Common problems and solutions, Symptom common causes possible corrections – Weil-McLain CGa User Manual

Page 23

User’s Information Manual

Part Number 550-110-592/0408

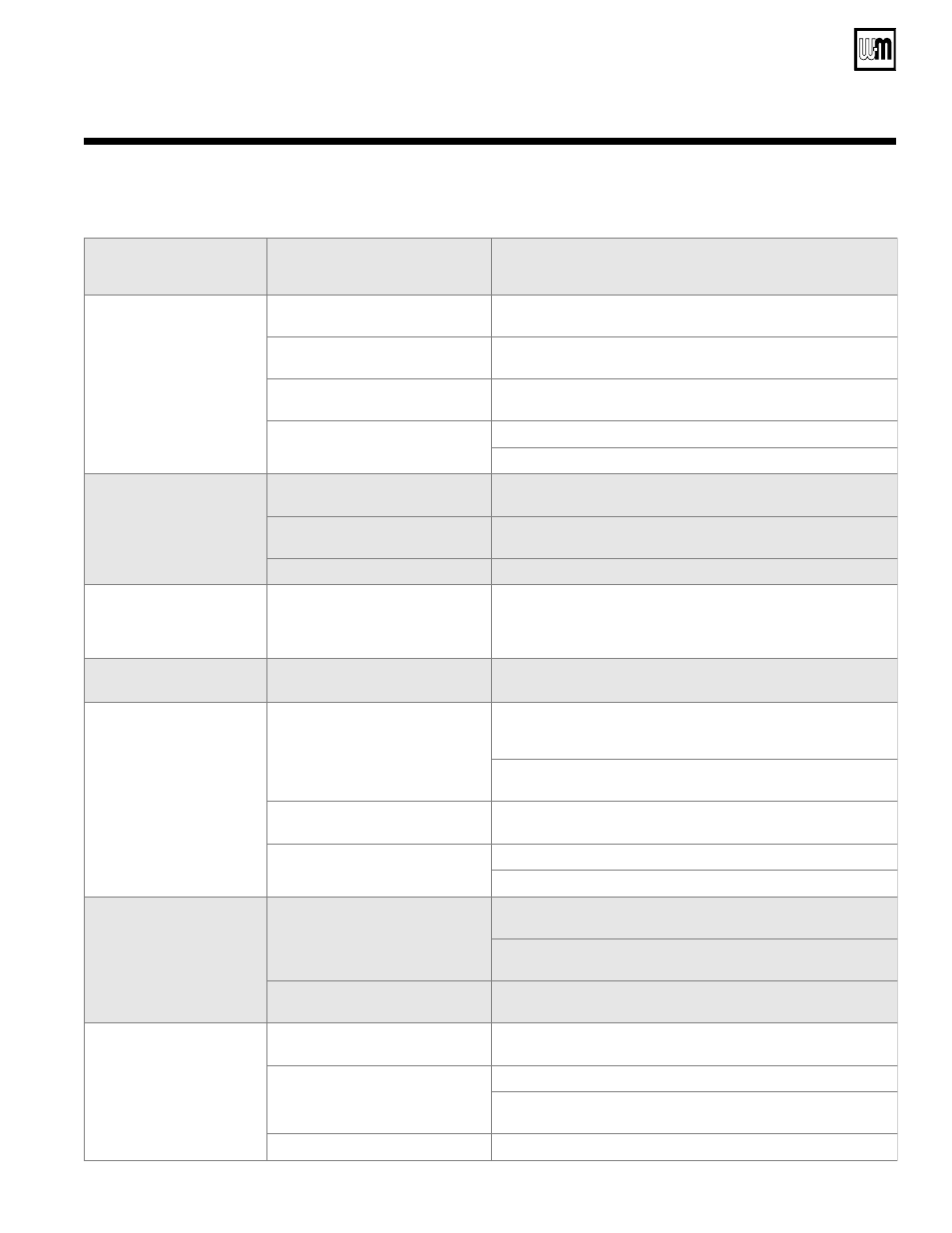

Common problems and solutions

Symptom

Common Causes

Possible Corrections

Rapid cycling —

boiler turns on and

off frequently

Thermostat installed where drafts

or heat affect reading

Locate thermostat on inner wall away from heat sources or cool

drafts.

Heat anticipator in thermostat

adjusted incorrectly

Adjust thermostat per manufacturer's instructions.

Incorrect limit setting

Set limit according to system needs. Maximum setting is 220˚F.

Increase limit setting to decrease cycling.

Insufficient water flow through

boiler

Check all valves to and from boiler. Return to proper setting.

Confirm circulator size.

Frequent release of

water through relief

valve

Expansion tank sized too small

Call qualified service technician to check expansion tank

operation and size.

Flooded expansion tank

Call qualified service technician to check expansion tank

operation.

Inoperative limit control

Call qualified service technician to replace limit control.

Need to frequently

add makeup water

Leaks in boiler or piping

Have qualified service technician repair leaks at once to avoid

constant use of makeup water. Makeup water can cause

mineral deposits which, in turn, can cause boiler section failure.

Do not use petroleum-base stop-leak compounds.

Black water

condition

Oxygen corrosion due to leaks in

boiler and piping

Have qualified service technician repair at once. Keep pH of

water between 7.0 to 8.5.

Popping or

percolating noise

heard in boiler

Mineral deposits in sections due

to constant use of makeup water

Call qualified service technician to de-lime boiler, if necessary.

In some cases, deposits will be too heavy to remove with de-

liming procedures.

Have qualified service technician repair leaks to eliminate need

for constant makeup water.

Incorrect pH of boiler water

Call qualified service technician to check pH level and correct.

pH should be maintained between 7.0 to 8.5.

Insufficient water flow through

boiler

Check all valves to and from boiler. Return to proper setting.

Confirm circulator size.

Metal flakes found in

vent outlet or vent —

flueway corrosion

Contaminated combustion air

supply — See page 3 in this

manual.

Remove any contaminating products. See page 3 in this

manual.

Provide outside air for combustion. Kit available through Weil-

McLain distributor. Have qualified service technician pipe-up kit.

Condensation of combustion

gases in boiler sections

Have qualified service technician inspect system piping and

controls to verify proper regulation of return water temperature.

Some radiators or

baseboard units do

not heat or are noisy

Air in system

Bleed air from system through air vents in radiators or

baseboard units.

Low system pressure

Fill to correct pressure.

Check for leaks in boiler or piping. Have qualified service

technician repair at once.

High limit set too low

Adjust high limit to higher setting.