Wayne-Dalton 8800 User Manual

Page 11

11

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the

Find a Dealer section online at www.wayne-dalton.com

Tools Needed:

iNST

alla

Tio

N

NoTe: For door section identification see page 4.

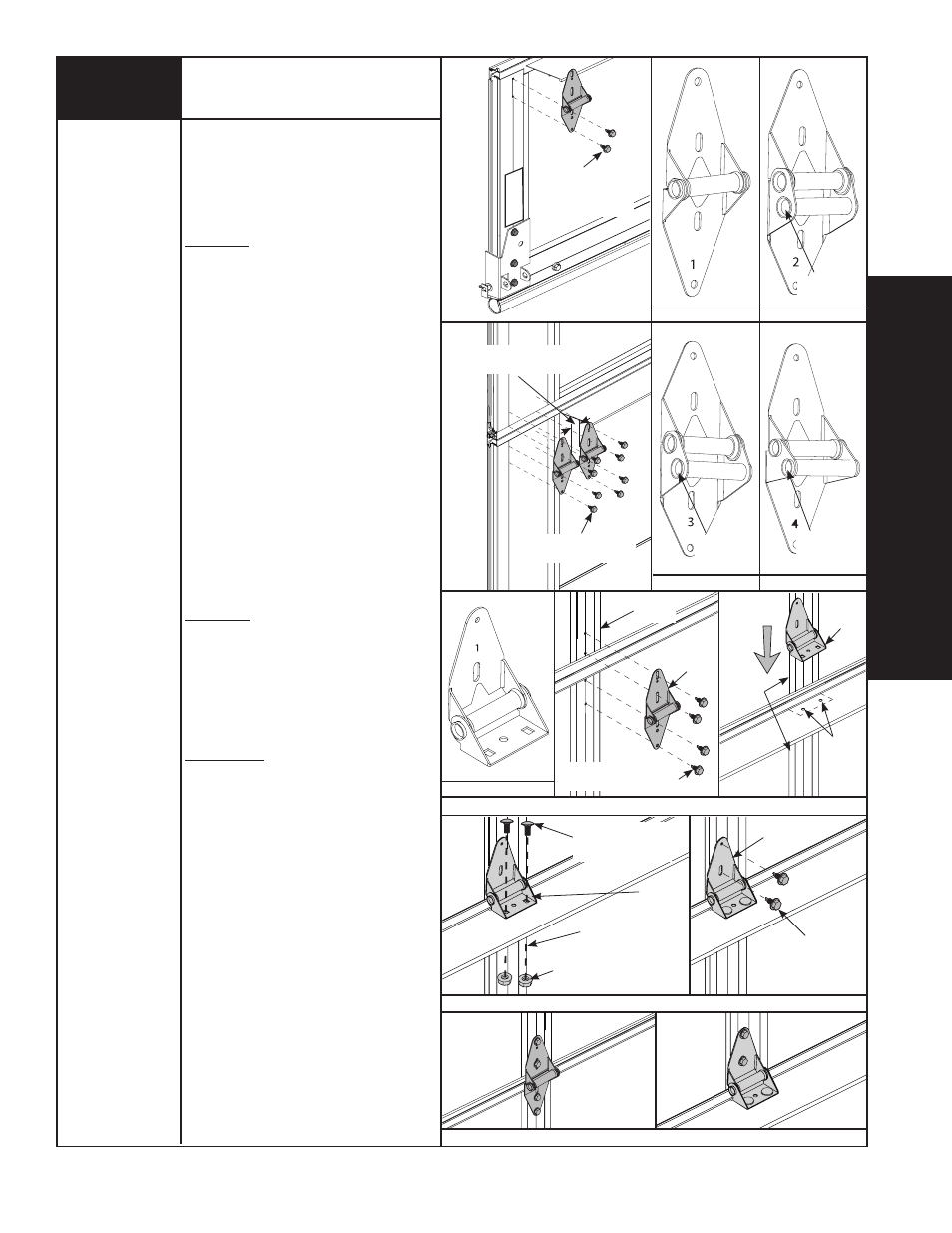

Locate the bottom section, using #1 end hinges for

the end stiles; depending on the width of your door

enough #1 half hinges for each of the pre-drilled

locations along the reinforcing fin.

end hinges:

Place (1) #1 end hinge at the top left hand corner

of the bottom section. Vertically align the slot/hole

of the lower (numbered) leaf with the small groove

in the end stile, and the center of the hinge with

the top edge of the section. Secure the end hinge

to the section using (2) 1/4” x 7/8” self drilling

screws. Insert a roller into appropriate end hinge

tube.

imPoRTaNT: WhEN PLACING ROLLERS

INTO END hINGES, ThE ROLLER MUST BE

INSERTED INTO ThE TUBE FURThEST AWAY

FROM ThE SECTION.

NoTe: If double end hinges are required, place

the second end hinge on the inner end stile and

secure using (2) 1/4” x 7/8” self drilling screw.

NoTe: Double end hinges will use long shaft

rollers.

Repeat for right hand side.

half hinges:

Align the half hinge with the pre-drilled holes of

the reinforcing fin, and secure the half hinge to the

reinforcing fin using (2) 1/4” x 5/8” Carriage Bolts

and (2) 1/4” Flanged hex Nuts.

Repeat for each of the pre-drilled locations along

the reinforcing fin.

center hinges:

Place (1) #1 end hinge at each of the center

stiles. Vertically align the slot/hole of the lower

(numbered) leaf with the small groove in the

center stiles, and the center of the hinge with the

top edge of the section. Secure the center hinges

to the section using (2) 1/4” x 7/8” self drilling

screw.

Repeat for all sections ExCEPT ThE TOP SECTION.

Use #2 end hinges for the lock section (second),

and enough #1 half hinges for each of the pre-

drilled locations along the reinforcing fin of the

second section.

Use #3 end hinges for the intermediate section

(third section), and enough #1 half hinges for each

of the pre-drilled locations along the reinforcing fin

of the third section.

Use #4 end hinges for the intermediate section

II (fourth section), and enough #1 half hinges

for each of the pre-drilled locations along the

reinforcing fin of the intermediate II section.

7

hinges

Power Drill

7/16” Socket

Driver

#1 hINGE

#2 END hINGE

#3 END hINGE

#4 END hINGE

ROLLER

PLACEMENT

ROLLER

PLACEMENT

ROLLER

PLACEMENT

hINGE

CENTER STILE

#1

hALF

hINGE

CENTER

STILES

CENTER hINGE PLACEMENT AND BEING ASSEMBLED

CENTER hINGE BEING ASSEMBLED

(2)1/4”- 20 x 5/8”

CARRIAGE BOLTS

(AS REqUIRED)

(2) 1/4” x 20

FLANGE hEx

NUT

#1 hALF hINGES

(2) 1/4” x 7/8”

SELF DRILLING

SCREWS

(8) 1/4” x 7/8” SELF

DRILLING SCREWS

PRE-

DRILLED

hOLES

(4) 1/4” x 7/8” SELF

DRILLING SCREWS

#1

hINGE

(2) 1/4” x 7/8” SELF

DRILLING SCREWS

1/4” SPACING

BETWEEN hINGES

CENTER

STILE

hINGE

CENTER hINGE ASSEMBLED