Installation, Continued) – Wayne CWS50 User Manual

Page 4

4

www.waynepumps.com

Installation

(Continued)

DRIVEN WELL

• Drive the point several feet below

the water table.

NOTE: A packer type foot valve can

be installed in the well (Figure 3,

Illustration B). This type of foot valve

allows the well to be filled with water

when priming and makes the inlet pipe

much easier to test for leaks. Follow

the manufacturer’s instructions when

installing the packer type foot valve.

As an alternative, an in-line check valve

can be used with a driven well (Figure

3, Illustration C). The pipe between the

check valve and the water level will

always be under a vacuum.

Leaking joints or couplings will allow

air to leak into the pipe and cause

abnormal pump operation. Make sure

to use pipe joint compound on all male

pipe threads.

DUG WELL, CISTERN, LAKE AND SPRING

INSTALLATION (FIGURE 17)

• Install a foot valve on inlet pipe and

lower into water.

The foot valve

should be at least 18

in. from the bottom of the well or sand

or sediment could be drawn into the

system.

NOTE: When a lake is used as a water

supply, make sure the inlet pipe is deep

enough to be submerged at all times.

Protect the pipe from damage from

swimmers and boats.

Slope the horizontal piping upward

toward the pump to prevent trapping

air. The pipe must be removed during

winter months or protected against

freezing.

Protect the pipe from damage from

swimmers and boats.

Install a screen

around the inlet

pipe to prevent the entrapment of

swimmers.

DEEP WELL INSTALLATION

DRILLED WELL (4 IN. OR LARGER) WITH

TWO PIPE JET (FIGURES 17 AND 4)

1. Assemble a 1-1/4 in. foot valve (not

included) to the jet body. A 1-1/4 in.

coupling is required to connect the

larger pipe to the jet assembly.

2. Connect the 1 in. pipe threads into

the smaller opening in the jet body.

3. Lower the jet into the well. Add pipe

as needed. Be sure to use pipe joint

compound on all male threads.

4. Position the jet 10 - 20 feet below

the lowest anticipated water level,

but never closer than 5 feet from the

bottom of the well, if possible.

5. Install a well seal to support the pipe

and prevent surface water and other

contaminants from entering the

well.

6. Install the horizontal pipe from

the well to the pump. Piping from

the vertical well pipe to the pump

should never be smaller than the

well pipes.

7. Slope both pipes upward toward

the pump to prevent trapping air. If

the horizontal distance exceeds 25

feet, see Chart 2 (on page 5) for the

recommended pipe sizes.

DUG WELL, CISTERN, LAKE AND SPRING

WITH TWO PIPE JET (FIGURE 17)

1. Install a 1-1/4 in. foot valve (not

included) to the jet body. A 1-1/4 in.

coupling is required to connect the

larger pipe to the jet assembly.

2. Connect the 1 in. pipe threads into

the smaller opening in the jet body.

3. Lower the jet into the water below

the lowest anticipated water level,

but never closer than 18 in. from

the bottom. Sand or debris may be

drawn into the system if the jet is

too close to the bottom.

4. Provide protection for the jet and

pipes against damage from boats

or swimmers if a lake is used for the

water supply.

Install a screen

around the inlet

pipe to prevent the entrapment of

swimmers.

5. Slope the horizontal pipes upward

toward the pump to prevent

trapping air. If horizontal distance

exceeds 25 feet, see Chart 2 for

recommended pipe sizes.

DRILLED WELL (2 IN.) WITH SINGLE PIPE

PACKER (FIGURES 17 AND 5)

NOTE: Single pipe packer jets rely on

the space between single pipe and

inside of well casing for return water to

operate jet. Two inch installations must

use 1-1/4 in. galvanized steel pipe with

special turned couplings (1-13/16 in.

O.D.) to avoid restricting flow of return

water back to jet.

1. Assemble the foot valve and packer

to the jet body.

2. Lubricate the rubber cups with

petroleum jelly.

3. Attach the first section of pipe and

lower jet into well.

4. Add pipe until the jet is positioned 5 -

15 feet below the lowest anticipated

water level. The jet should never be

closer than 5 feet from the bottom of

the well or sand and sediment may

be drawn into the system.

5. With the jet in position, fill the pipes

with water to make sure the rubber

cups are sealed against inside of the

well casing. It may be necessary to

move the jet up and down to seat

the cups.

6. Install the casing adapter and the

horizontal pipes.

Operating Instructions & Parts Manual

CWS50, CWS75 and CWS100

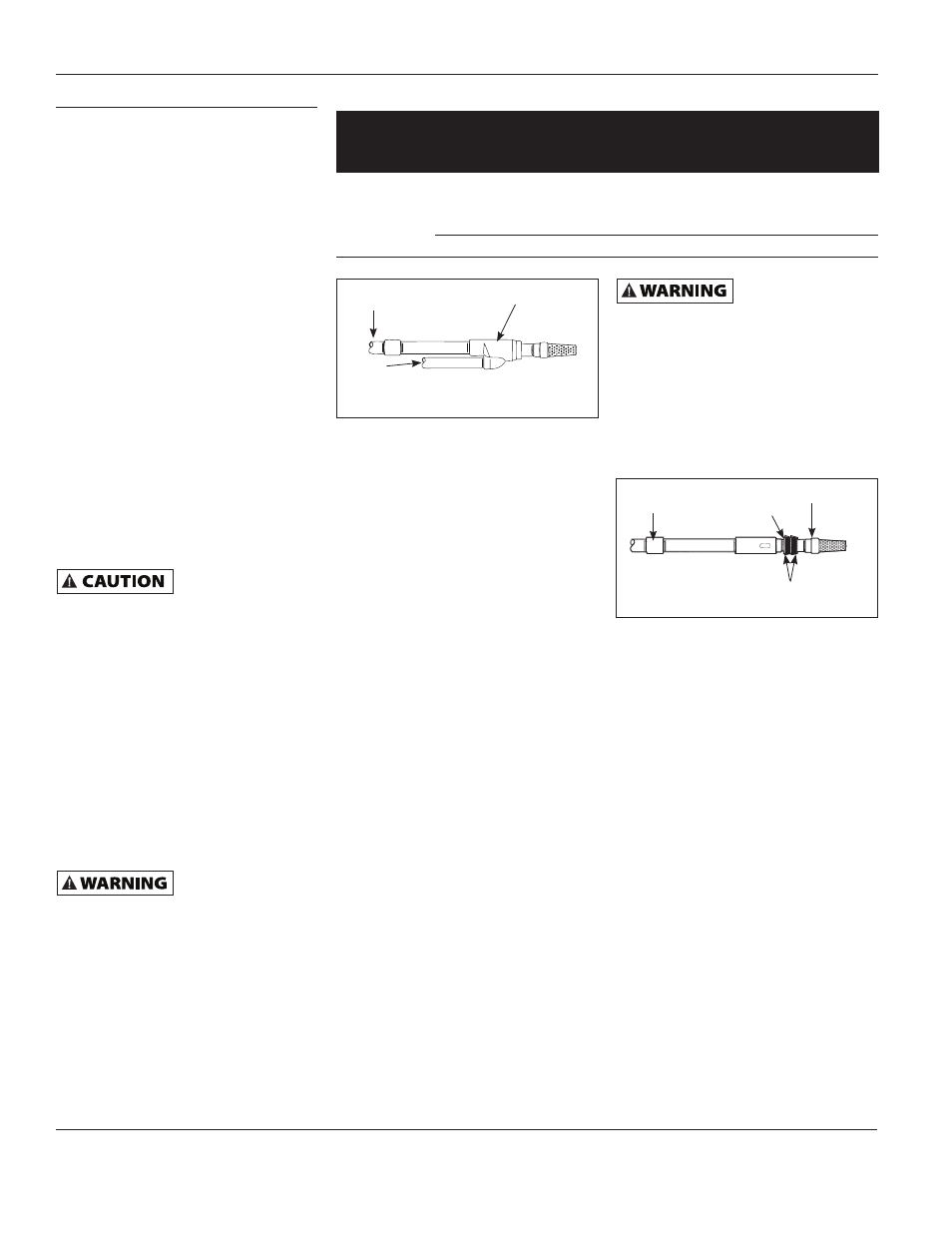

Figure 4 - Two Pipe Jet

Jet Body

Foot Valve

1-1/4 in. Pipe

1 in.

Pipe

Figure 5 - Single Pipe Jet

Packer

Foot Valve

1-1/4 in. Pipe

Cups

CHART 2 - PIPE SIZING

Pump Model

Pump

Opening

Horizontal Distance

(Feet)

0-25

26-100

Deep Well

Inlet:

Suction

1-1/4 in.

1-1/2 in.

Inlet: Drive

1 in.

1-1/4 in.

Outlet

3/4 in.

1 in.