General safety information, Pre-installation, Continued) – Wayne CWS50 User Manual

Page 2

2

Operating Instructions & Parts Manual

CWS50, CWS75 and CWS100

www.waynepumps.com

General Safety

Information

(Continued)

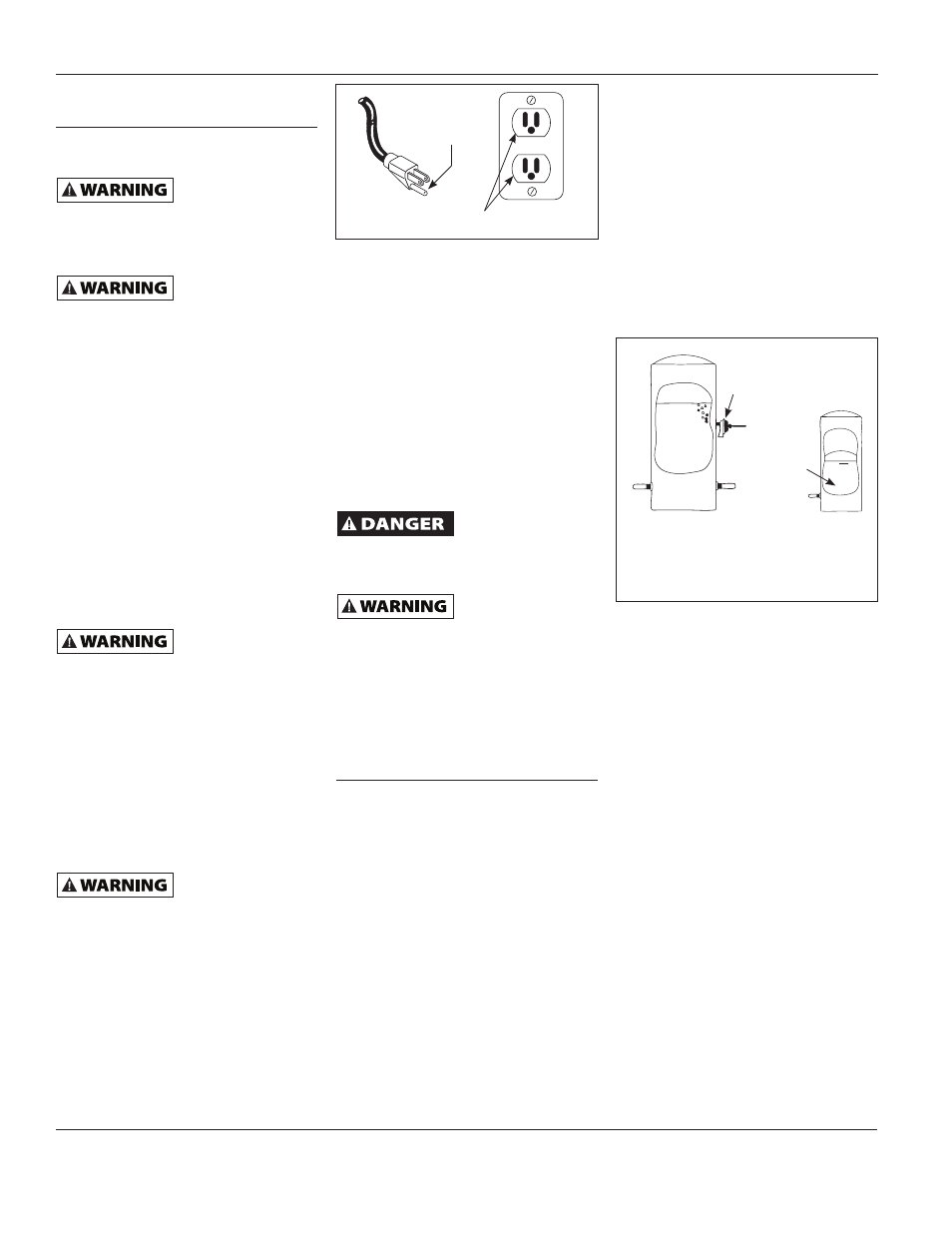

TANKS - CONVENTIONAL STORAGE

The function of the tank is to store a

quantity of water under pressure. When

full, the tank contains approximately

2/3 water and 1/3 compressed air. The

compressed air forces the water out

of the tank when a faucet is opened.

An air volume control automatically

replaces air lost or absorbed into the

water. The usable water, or draw-down

capacity, of the tank is approximately

1/6 of the tanks total volume when

operated on a “20-40” pressure setting

(Figure 2).

TANKS - PRE-CHARGED STORAGE

A pre-charged storage tank has a

flexible bladder or diaphragm that acts

as a barrier between the compressed

air and water. This barrier prevents the

air from being absorbed into the water

and allows the water to be acted on by

compressed air at initially higher than

atmospheric pressures (pre-charged).

More usable water is provided than

with a conventional type tank. Pre-

charged tanks are specified in terms

of a conventional tank. For example,

a 20 gallon pre-charged tank will have

the same usable water or draw-down

capacity as a 40 gallon conventional

tank, but the tank is smaller in size

(Figure 2).

PRESSURE SWITCH

The pressure switch provides for

automatic operation. The pump starts

when pressure drops to a cut-in setting.

The pump stops when pressure reaches

a cut-out setting.

12.Do not run the pump dry or damage

will occur and will void warranty.

This pump is

designed for indoor

installation only. Failure to install

indoors will significantly increase the

risk of injury or death from electrical

shock.

All wiring should

be performed by a

licensed or certified electrician.

13. For maximum safety, the unit should

be connected to a grounded circuit

equipped with a ground fault

interrupter device.

14. Before installing the pump, have

the electrical outlet checked by a

licensed or certified electrician to

make sure the outlet is properly

grounded.

15. Make sure the line voltage and

frequency of electrical current supply

agrees with the motor wiring.

16. Do not attempt repairs to the

electric motor. All repairs to the

motor must be completed at a

licensed or certified electrical motor

repair shop.

Do not touch an

operating motor.

Modern motors are designed to operate

at high temperatures.

17. Avoid kinking electrical cord

and protect electrical cord from

sharp objects, hot surfaces,

oil and chemicals. Replace or

repair damaged or worn cords

immediately.

18. Keep fingers and foreign objects

away from ventilation and other

openings. Do not insert any objects

into the motor.

Risk of electric

shock! Never

connect the green (or green and yellow

wire) to a live terminal!

19. To reduce the risk of electrical

shock, the pump should be plugged

directly into a properly installed

and grounded 3-prong grounding

type receptacle, as shown in

Figure 1. The green (or green and

yellow) conductor in the cord is the

grounding wire. The motor must be

securely and adequately grounded

for protection against shock.

20. Where a 2-prong is encountered,

replace the plug with a properly

grounded 3-prong receptacle in

accordance with the National

Electrical Code, local codes and

ordinances. To ensure a proper

ground, the grounding means must

be tested by a licensed or certified

electrician.

21. Use only 3-wire extension cords that

have a 3-prong, ground type plug,

and 3-pole receptacles that accept

the equipment plug.

22. Use wire of adequate size to

minimize voltage drop at the motor.

Do not handle pump

or pump motor with

wet hands, when standing on a wet

or damp surface or when standing in

water. Fatal electrical shock could occur.

Pump motor is

equipped with an

automatic resetting thermal protector

and may restart unexpectedly. Protector

tripping is an indication of motor

overloading because of operating pump

at low heads (low discharge restriction),

excessively high or low voltage,

inadequate wiring, incorrect motor

connections or defective motor or pump.

Pre-Installation

WATER SUPPLIES

The water supplies illustrated in Figure

26 are possible sources for water. These

water supplies can be divided into two

categories:

SURFACE WATER

Water from a lake, stream, pond and

cistern. This water is usually not fit

for human consumption, but may be

suitable for washing, irrigation or other

household uses.

GROUND WATER

Water found in the water bearing

stratum at various levels beneath the

earth. Of all the fresh water found on

earth only 3 percent is found on the

surface and 97 percent is underground.

TEST

RESET

Figure 1

Grounded Pin

Grounded Outlet

Figure 2 - Conventional and

Pre-charged Storage Tanks

Air Volume

Control

Conventional

Tank

Pre-charged

Tank

Bladder