Unified Brands VENTILATION SYSTEMS User Manual

Page 5

2

integral water wash system cleans the inside of

the grease extraction chamber either by manual

activation of the Wash Start button or by a

programmable timer. The duration of the wash is

electrically controlled. The wash system is also

activated by an electrical thermostat or a manual

switch in the event of a fire condition. A surface

fire extinguishing system is required and may be

factory supplied.

Auto Wash control panels are provided with these

systems. Wiring diagrams are provided with this

manual.

Installation shall be in accordance with NFPA 96.

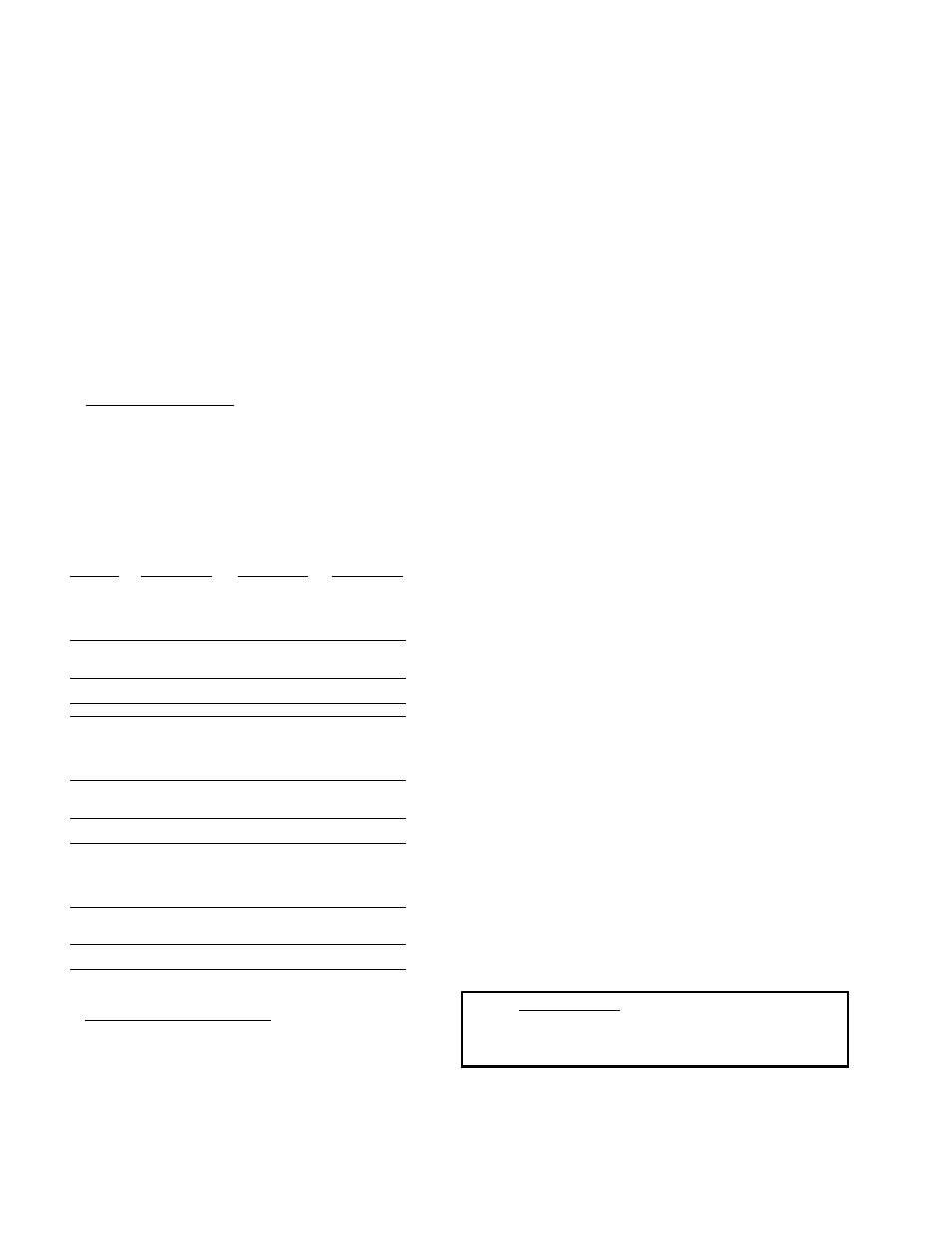

D.Airflow Requirements

Minimum exhaust airflow requirements and

maximum make-up airflow requirements [where

air is introduced directly inside the canopy] are

shown on the chart below. These flow rates were

established under laboratory conditions. Greater

exhaust airflows and/or reduced make-up airflows

may be required for complete capture.

CFM REQUIREMENTS

400°F Cooking

600°F Cooking

700°F Cooking

Model No.

Surface Equip.

Surface Equip.

Surface Equip.

AFWO,AFBO 200

300

525

AFDO,AFWP

AFBP,AFDP

AFWE,AFDE

AFBE

AFWI,AFBI

250[175]

N/R

N/R

AFDI,AFWD

AFBD,AFDD

AFIO,AFIP

250

400

600

AFIE

AFII,AFID

300[150]

N/R

N/R

AXWO,AXBO

200

275

525

AXDO,AXWP

AXBP,AXDP

AXWE,AXDE

AXBE

AXWI,AXBI

250[175]

N/R

N/R

AXDI,AXWD

AXBD,AXDD

AXIO,AXIP

250

400

600

AXII

300[150]

N/R

N/R

AWWO,AWWP

194

270

*525

AWWE,AWDO

AWDP,AWDE

AWBO,AWBP

AWBE

AWWI,AWBI

250[190]

270[146]

N/R

AWDI,AWWD

AWBD,AWDD

AWTE,AWTP

400

420

N/R

AWTO

N/R = Not Recommended

*=Manufacturer's test results not yet submitted to U.L. for capture tests.

E.Fire Extinguishing Systems

There are two basic types of ventilator fire

extinguishing systems in use today:

Wet Chemical and Water Mist. Wet Chemical

Systems may be all or partially factory installed

[by the Fire System Manufacturer]; final hook up

and certification at job site is done by the Fire

System Manufacturer's local representative.

These systems must be periodially inspected,

and critical parts replaced. It is suggested that a

service contract be purchased from the local

representative. For further details refer to the

manufacturer's technical manual.

AVTEC manufactures and installs a water mist

fire extinguishing system, "MIST-A-FIRE", that

connects to the building fire sprinkler system

[must be "wet" type system]. Final connect of this

system must be done in the field by the sprinkler

contractor or authorized plumber. A

certification/inspection report is done by an

authorized AVTEC representative. Periodic

inspection is generally required, but replacement

of parts and periodic maintenance is virtually

eliminated. For further details, refer to the

AVTEC MIST-A-FIRE Installation and Operating

Technical Manual.

II. INSTALLING THE VENTILATOR

The ventilator is supplied with brackets to facilitate

the attachment of hanger rods to the vent. Hanger

rods should be attached to all brackets to ensure

proper support.

A.Ascertain that the ceiling/roof structure is strong

enough to support the weight of the hood and

support system. The approximate weight of the

hood is shown below:

45 lbs/linear ft. for hoods w/o AMU plenums.

55 lbs/linear ft. for hoods w/AMU plenums.

125 lbs for fire control cabinet.

B.Carefully uncrate the hood so as not to dent or

scratch the outer surface.

C.Position the hood on the floor in approximately

its final installed location.

D.Use 1/2" threaded rods to hang the hood. The

hanger rods should be approximately 1/2" closer

to the wall at the structural attachment location

than at the top of the hood. [see fig. #4] This

ensures that the hood is held tightly against the

wall.

Note! Do not remove Support Brace until Ventilator

installation is complete. Upon completion of

installation, dispose of Support Brace and replace the

Acorn Nuts to their original locations.