Unified Brands VENTILATION SYSTEMS User Manual

Page 25

22

D. Grease Collection Receptacle

Should be emptied at least once a day, and

cleaned daily with a strong detergent.

E. Hood Canopy

1. Inside hood canopy should be wiped

down as needed. The area at the exhaust

intake openings should be wiped down daily.

2. Inspect inside of extraction chamber at

least monthly, to insure proper cleaning and

that the trough is free of foreign matter.

F. Detergent System

1. Detergent tank should be checked at

least weekly; and cleaned every six months.

Always keep cover on tight to prevent

spillage and evaporation.

2. A colloid type detergent, is recommended

due

to

its

non-caustic,

non-toxic,

biodegradable characteristics. It will not

damage the rubber or synthetic parts of the

pumping system. AVTEC recommends

using EVAC Detergent. Available thru your

local Service Agents or call Factory. See

page 28 for more information.

3. All fittings should be checked for air

tightness at least monthly.

4. Foot check valve should be cleaned every

six months.

G. Fusible Link Replacement

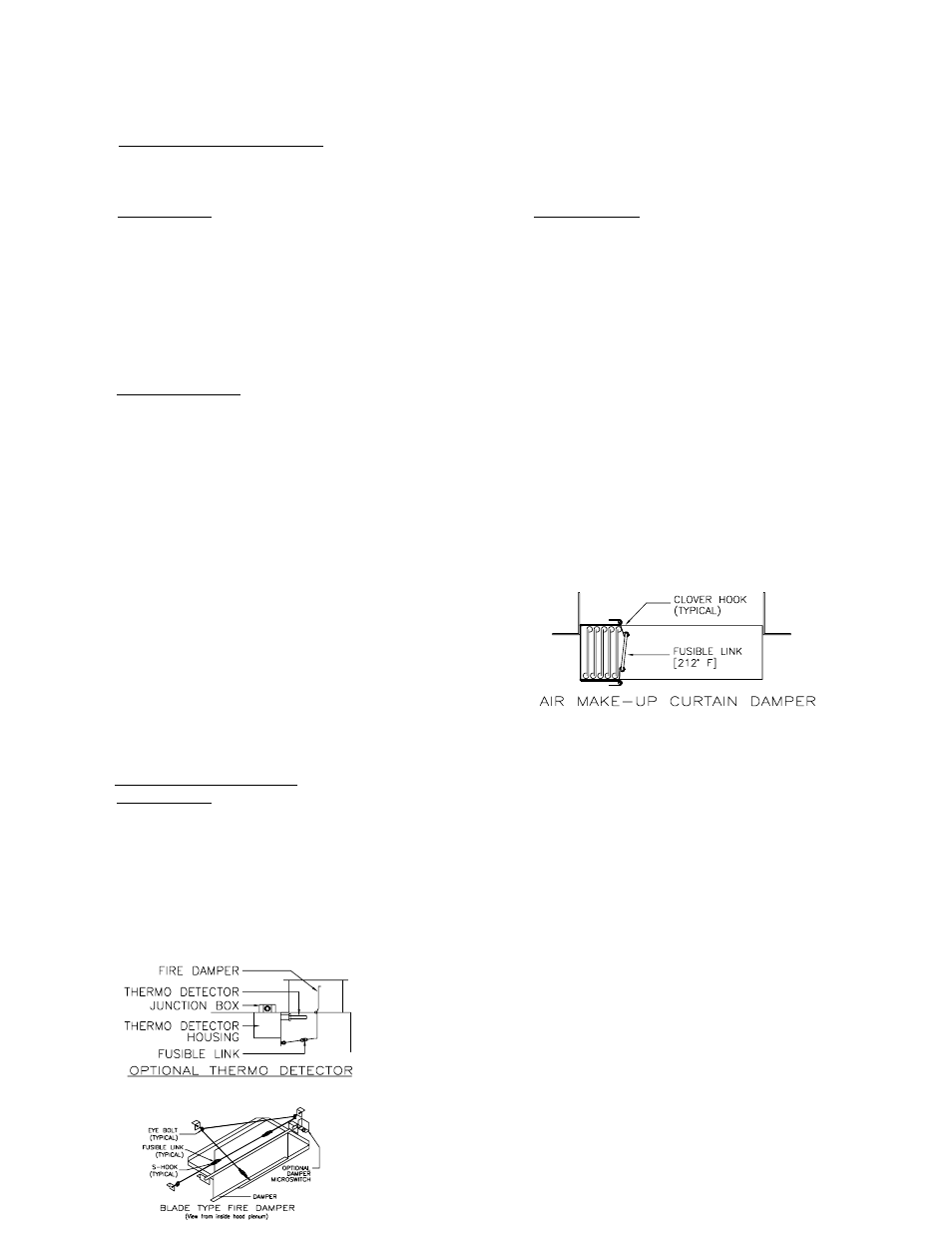

1. Blade Type [Refer to fig. 27]

Exhaust damper fusible links are rated at

350°F [P/N AS LNK0302] and Air Make-

up damper fusible links are rated at 286°F

[P/N AS LNK0303]. Fusible links shall be

replaced at least annually per NFPA 96, 8-

2.1.2. New "S" hooks [P/N FA HOK0301]

should be used whenever the fusible links

are replaced.

Cable tension can be adjusted by moving the

eye-bolts in and out to ensure that the

damper is fully open.

fig. 27

2. Curtain Type [Refer to fig. 28]

When make-up air is brought directly into

the capture area a fire damper is required at

the duct collar.

The curtain damper is

equipped with a 212°F fusible link [P/N AS

LNK0006]. Fusible links shall be replaced at

least annually per NFPA 96, 8-2.1.2. New

“s” hooks [P/N FA HOK0301] should be

installed whenever the fusible links are

replaced. These links are replaced by

unfolding the retaining strap and removing

the clover hook and fusible link as a unit.

Be careful to hold the curtain damper in

place as a spring will try to pull it closed.

fig. 28