Unified Brands VENTILATION SYSTEMS User Manual

Page 22

19

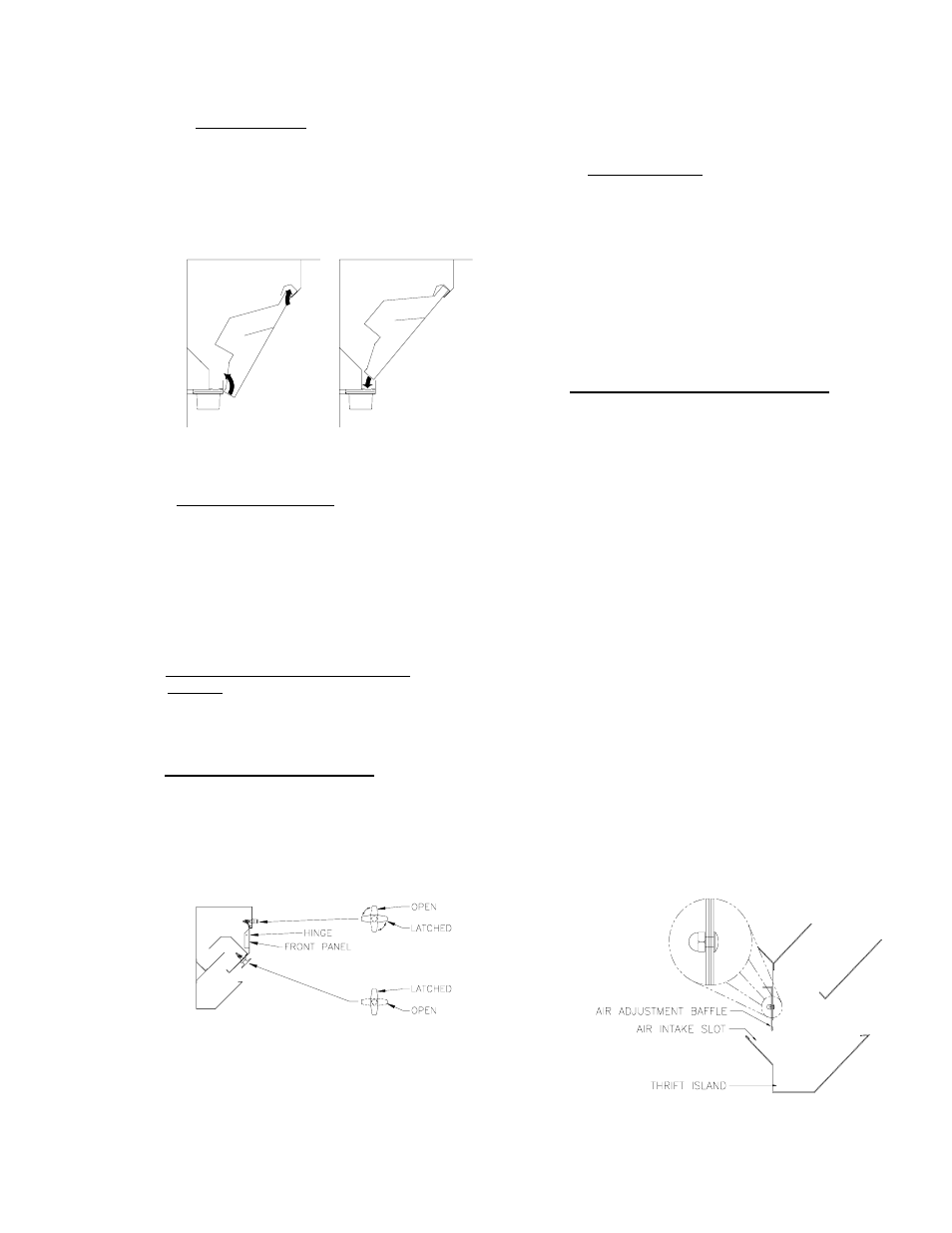

[Refer to fig. 21]

Grease extractor modules are installed

by sliding the top [narrow] part of the

module into the upper retaining slot and

then lowering the bottom part of the

module into the grease trough slot.

fig. 21

NOTE: Handle faces towards capture area.

2. Grease Receptacles

Grease receptacles are located at each

end of each ventilator section. These

must be cleaned out periodically. The

frequency of this cleaning is dependent

upon the type of equipment used beneath

the ventilator and the duration of its use.

It is suggested that initially the grease

receptacles be emptied daily.

C. Auto Wash Grease Extractors [AW

Models]

These type ventilators have an automatic

wash cycle which requires only occasional

wiping down of inside grease extractor.

1. Grease Extraction Chamber

The front panel is hinged to facilitate

access to the nozzles and grease

extraction baffles.

[Refer to fig.22]

fig. 22

To open, turn all front panel latches

clockwise to the open [unlatched] position

and swing the bottom of the front panel out.

"Kickstands" are provided at each end of the

ventilator section to hold the front panel

open.

2

.

Spray Nozzles

Spray nozzles for hot water wash and

cold water mist are protected from

clogging by wye-strainers located in the

plumbing enclosure. However, scale and

contaminants will accumulate in time and

these will require occasional cleaning to

assure proper wash down and spray

distribution. A paper clip or other pointed

object should be used to scrape

contaminants from the nozzles.

D. Air Adjustment Baffle [Refer to fig. 23]

Some grease extractor models may be

equipped with air adjustment baffles at the

exhaust intake slot. These baffles may be

adjusted to increase or decrease the intake

slot, according to the cfm desired or required

for varying pieces of cooking equipment

underneath. The length of the baffles varies

according to project design specifications and

conditions. The standard opening of nominal 3"

yields approximately 250 cfm/linear ft. and is

used for most cooking appliances. Air flow may

be reduced to a low as 150 cfm/linear ft. for

ovens, steamers, etc. depending on local job

conditions. Adjusting the slot to nominal 1-3/4"

opening will yield approximately 150 cfm/linear

ft.

The Thrift Island Series ventilators uses only

one grease extraction chamber and is designed

for 250-270 cfm/linear ft. on the cooking side

and 150 cfm/linear ft. on the oven/steamer side.

These units are provided with air adjustment

baffles to "fine-tune" the balance of air from

each side, and to change air velocity as job

conditions dictate.

fig. 23