Unified Brands VENTILATION SYSTEMS User Manual

Page 24

21

fig. 26

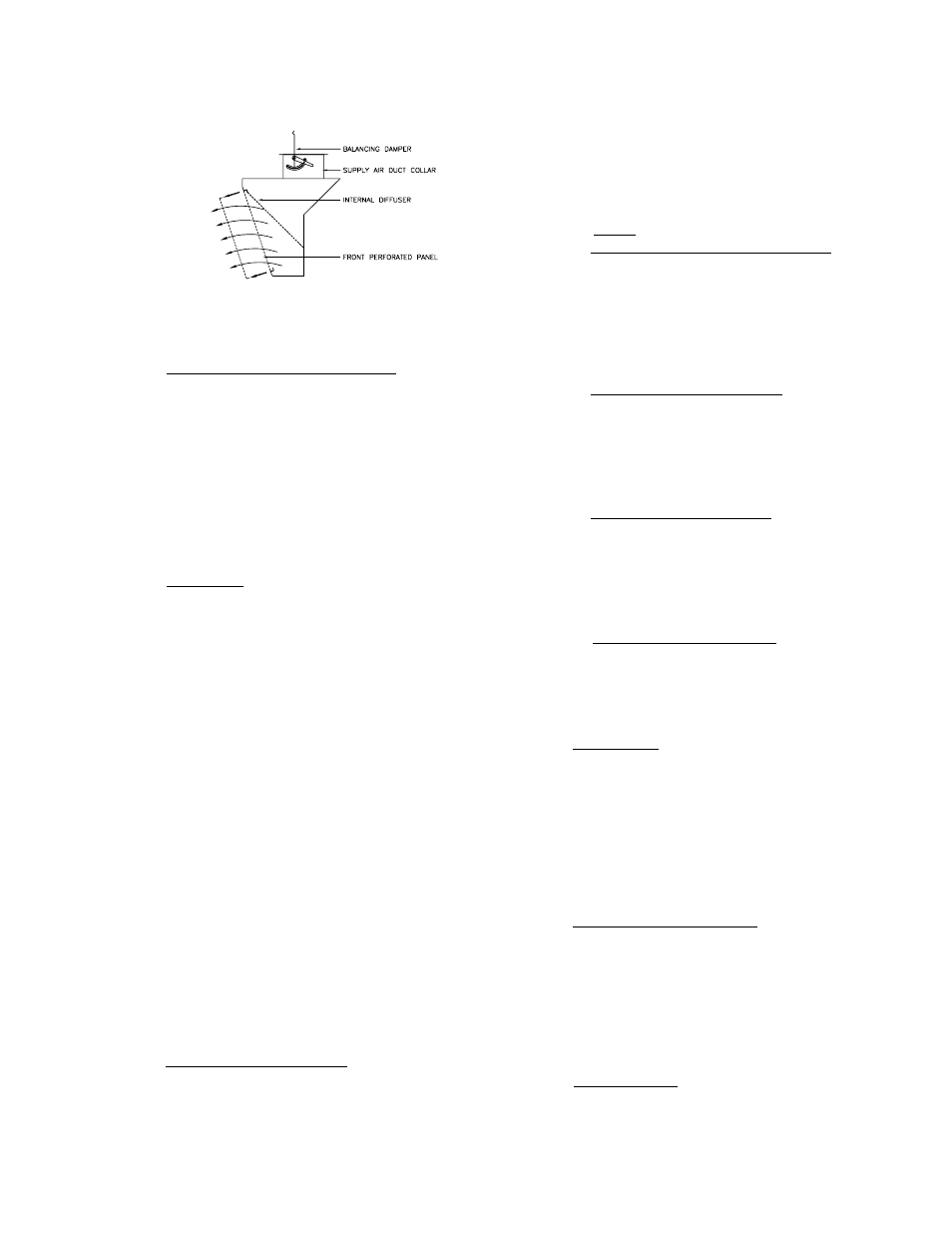

3. Slot-Type Internal Air Make-Up

Hoods provided with "Short-Cycle" type air

make-up only are supplied with a slot which is

designed to direct the air along the top of the

hood and into the exhaust plenum inlet. The

volume of air can be regulated through the

use of a combination balancing damper and

fire damper located on top of the air make-up

plenum. [Refer to fig. 24]

G.Auto Wash

Plenum wash down is a feature of the Energy

Aire Ventilator which eliminates the need to

frequently clean the grease extraction area.

The wash down cycle normally occurs

immediately after the cooking period and

does not occur while the fans are ON. A

water/detergent mixture is sprayed from a

series of nozzles to remove accumulated

grease and grime which flows out through the

drain. A vacuum breaker/check valve must

be installed upstream of the detergent

injection point [and a minimum of 6" higher

than the ventilator inlet] to prevent detergent

from backflowing into the building water

supply. [Refer to fig. 14]. Hot water should

be at 120

oF and pressure must be between

20 psig and 40 psig flow. The duration of the

wash down cycle is adjustable and will vary

depending of length of cooking cycle, type of

cooking equipment used, concentration of

detergent, water pressure and temperature,

among other considerations. See Sec. VI, b.,

"Setting the PAWS", for instructions.

**Note: See Page 28 cut sheet for detergent

information.

H.Cold Water Mist [Optional]

To aid in extracting particulates from the

exhausted air and to aid in cooling the

exhaust, a cold water mist option is available.

This is especially useful with charbroilers.

Cold water mist is a fine spray within the

plenum area which runs whenever the fans

are ON. This com- plements the baffle

system on Energy Aire Systems and does not

replace the wash down feature.

Water

pressure should be between 30-40 psig flow.

I. Lights

1. Surface Mounted - Incandescent

To replace the bulb unscrew the globe.

Fixture will accept bulbs up to a maximum of

100 watts. Screw the bulb into the socket

and then proceed to screw the globe tightly

in position. Be sure that the inner silicone

gasket is in place before installing the globe

2. Recessed - Incandescent

To replace the bulb, loosen screws which

retain diffuser panel. Diffuser panel is

attached to housing with a cable to prevent it

from falling or becoming lost. Fixture will

accept bulbs up to a maximum of 150 watts.

3. Recessed - Fluorescent

To replace bulbs, unscrew diffuser panel.

The diffuser is attached to a housing with a

cable to prevent it from falling or being lost.

Two [2] bulbs are required for each fixture.

Fixture Size

[nominal]

Bulb Size

24"

[2] F20T12TS

36"

[2] F30T12RS

48"

[2] F40T12RS

VIII. PERIODIC MAINTENANCE

A.Baffle Filters

Filters should be removed and cleaned at least

weekly, depending on hours of operation.

Filters may be cleaned by soaking in a strong

detergent

solution,

or

running

thru

a

dishwasher. When replacing, make sure filters

and handles are running vertically, and filters

are seated properly, refer to Sec. VII, A.1, pg.

15.

B.Modular Grease Extractors

Modules should be removed and cleaned at

least weekly, depending on hours of operation.

Modules may be cleaned with a brush and a

strong detergent solution, or run thru the

dishwasher. When replacing modules, make

sure they are seated properly, refer to Sec. VII,

B.1, pg. 16.

C.Grease Trough

Should be checked weekly for grease build up,

and

cleaned

with

strong

detergent,

if

necessary.