Easy engineering high reliability, Disturbance overshoot adjustment, Fine tuning – Omron Smart Process Control CJ-Series User Manual

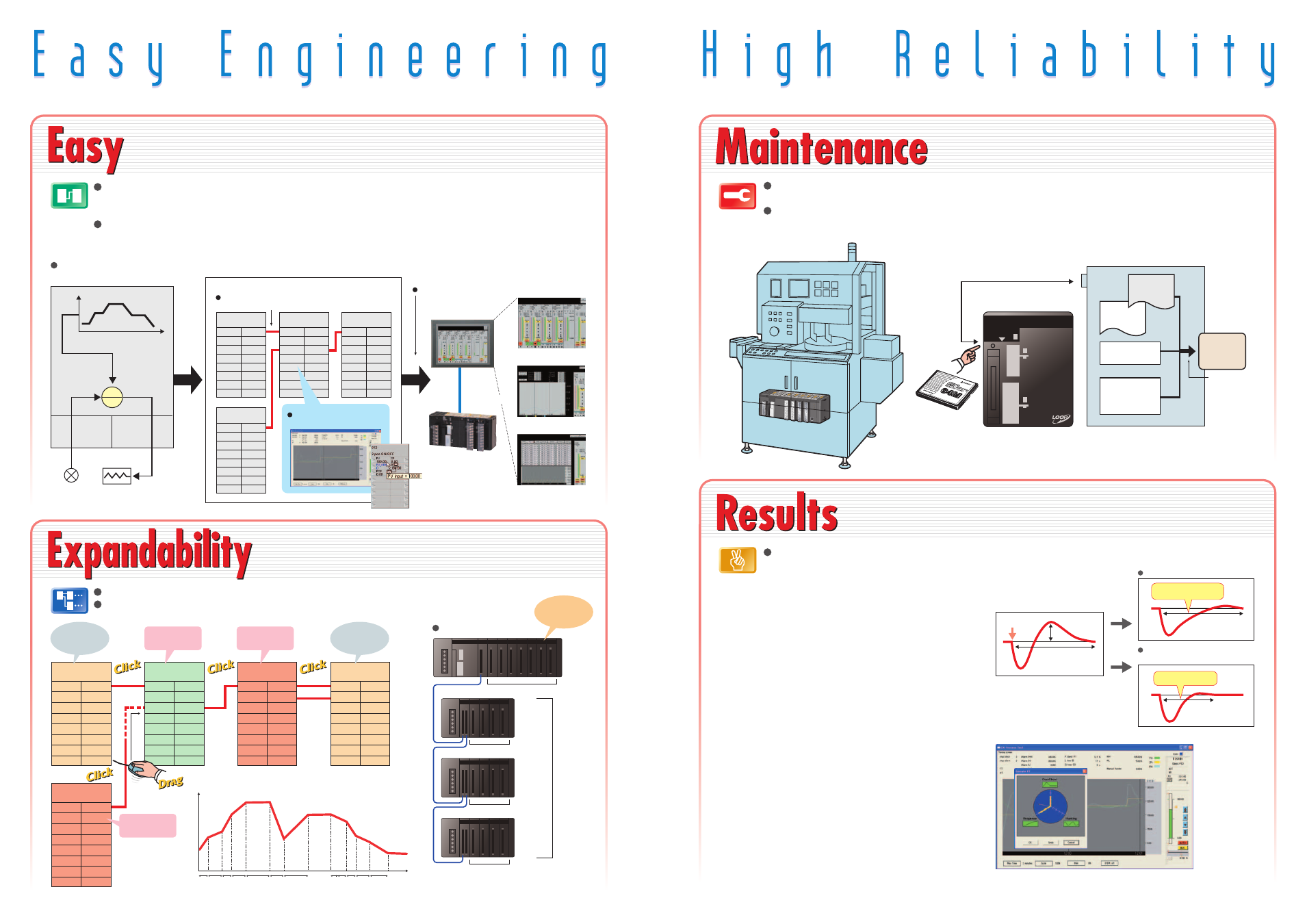

Page 3: New algorithm further enhances control stability, Optimum tuning to suit the application, Engineering example: program control, System configuration

5

New Algorithm Further Enhances Control

Stability

Disturbance Overshoot Adjustment

Optimum Tuning to Suit the Application

Fine Tuning

Disturbance

Disturbance generated

Time required to

stabilize

Overshoot

Conventional PID gain adjustment

Using the Disturbance

Overshoot Adjustment function

Longer time required

to stabilize

Faster stabilization

This function restrains overshoot when a disturbance is

generated, allowing faster stabilization.

[Example]

• Temperature drops when adding objects to a furnace

• Control disturbances when retooling

Adjust PVs, SPs, and MVs while monitoring, and save

data as CSV files from the software tuning window.

Autotuning (AT) and fine-tuning functions can also be

used for automatically calculating PID constants (see note

2).

Note 1: For details on CS-series Loop Control Boards, refer to the PLC-based

Process Control Catalog (Cat. No. P051).

2: Control can be fine-tuned by automatically tuning PID parameters using

previous control parameters and three user-set requirements to execute

fuzzy logic.

CS-Process Tool Tuning Window

Sequence

program

Function

block

program

I/O memory

Parameter Area

CPU Unit

Memory

Card

Condition: Pin 7 is ON

CX-Process Tool (Software for Personal Computer)

Face Plate Auto-Builder for NS

Touch panel windows are automatically generated.

Segment program

parameter setting window

Tuning window

NT-series PT

Loop-control CPU Unit

Serial or

Ethernet

communications

Control window

SP

TIC

Input

channel 1

Output

channel 1

Time

RSP

PV

MV

Temperature

input

Heater output

Loop-control CPU Unit

Y1

Y2

Y3

Y4

X1

X2

X3

X4

PV

RSP

MV

Analog Output

Field Terminal

Analog Input

Field Terminal

Y1

Segment

Program

Basic PID

Adjust PID and other parameters

in the tuning window.

Expansion Rack

Expansion Rack

Expansion Rack

10 Units max.

10 Units max.

10 Units max.

10 Units max.

Note: CJ1G-CPU44P/45P

(CJ1G-CPU42P/43P: Expand up to 2 Racks)

Analog Input

Field Terminal

MV

DV

SP

PV

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

RSP

Basic PID

Split Conversion

Y1

X1

Y2

Y1

X1

Y2

Segment

Program 2

X1

X2

X3

X4

X5

X6

X7

X8

Analog Output

Field Terminal

Function blocks make loop-control programming easy. You can also create

CX-Process Tool tuning windows to help adjust loops. Controller faceplates

can be created automatically for touch panel displays.

Lineup includes low-cost models that use up to 50 function

blocks and models that allow up to 300 blocks designed for

large-scale systems and complicated operations.

Sequence control programs: Standardize and simplify programs using structured programming. Special I/O

Unit and CPU Bus Unit settings are easy with function blocks (using ladder programming language or

structured text).

Loop control programs: By combining function blocks, a wide array of control methods can be easily

configured, from basic PID control used by Temperature Controllers to program, cascade, and feed-forward

control. Easily display values, such as temperatures, in engineering units, allowing you to check operation.

Simple backup function enables backup, recovery, and comparison of all PLC data including the

function block programs for the Loop Control Board using the Memory Card.

Save tag settings, comments, annotations, and connection data created using the CX-Process

Tool to either a Memory Card or a Loop-control CPU Unit.

Loop control: Proven functionality of Temperature Controllers and CS-series Loop Control

Boards (see note 1) in a compact size.

Loop control: Programming with function blocks to suit the application.

System configuration: Choose and combine functions from a broad selection of I/O Units.

Engineering Example: Program Control

Analog

Input

Unit

Analog

Output

Unit

Combine function blocks and connect graphically

using the mouse.

1

2

3

Read data from

Analog Input

Units

Perform PID

control

Perform

heating/cooling

control

Perform program

control

Control output

from Analog

Output Unit

Process Input

Units, Analog

I/O Units, etc.

System Configuration

Expansion

Rack: 3

Racks

max.

(See note.)

Simply turn the DIP Switch ON/OFF to save or read the

user program including function blocks using the

Memory Card.

Consolidating OMRON's expertise in temperature and process control

cultivated over many years to provide you with effortless solutions

using proven algorithms.

Press the

Memory Card

power supply

switch for 3 s.

Simple backup

to Memory

Card, including

function block

data.

Note: Supported by unit version 3.0 or later.

T0

T1 T2

T3

T4

T5

T6

T97 T98 T99 T100

TIME

Set point (SP)

4