Introducing the new style of loop control, Down-sizing, Integrated loop control and sequence control – Omron Smart Process Control CJ-Series User Manual

Page 2: Loop-control cpu unit, Sequence control engine loop control engine

3

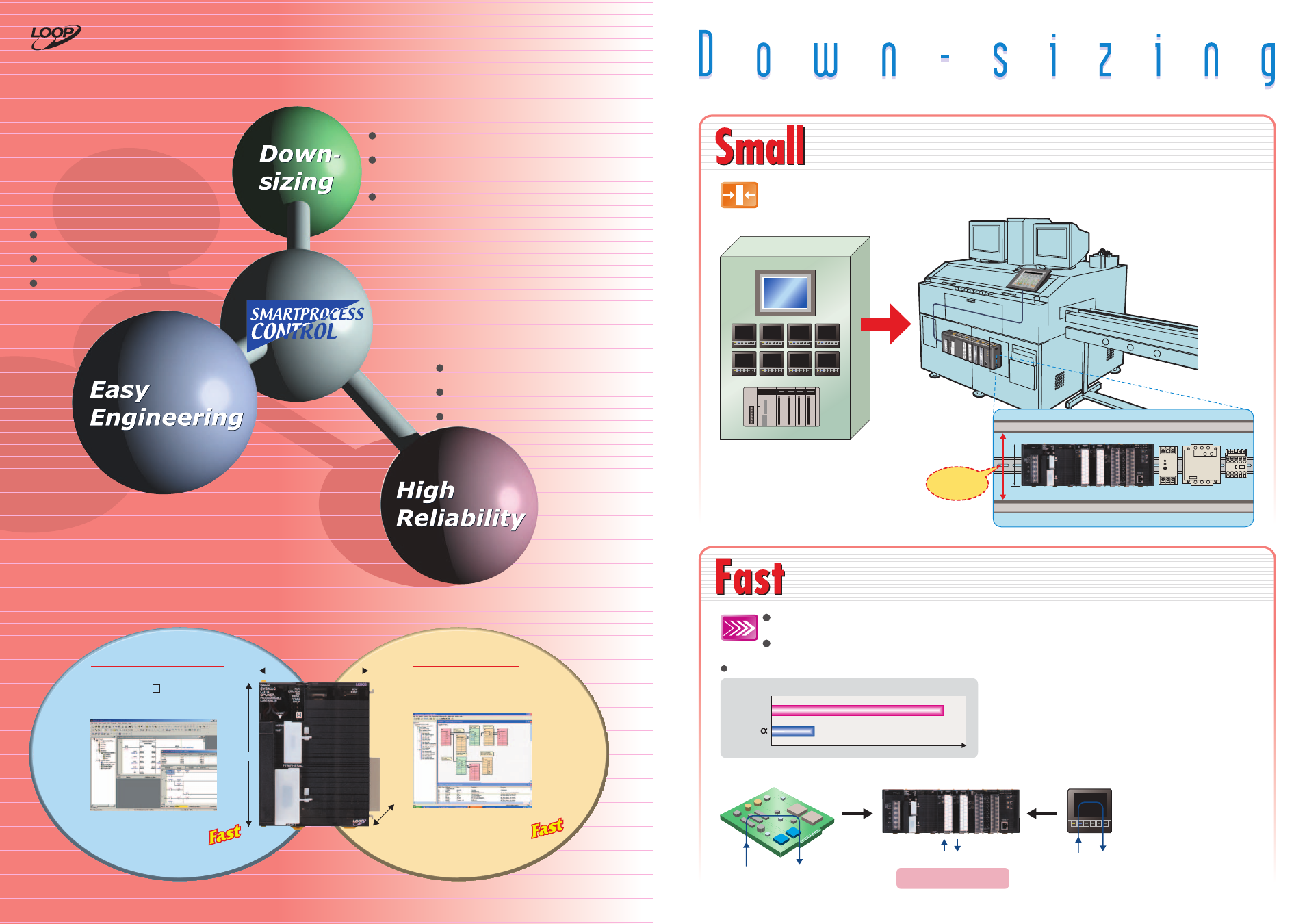

Introducing the New Style of Loop Control

Advanced controller functions integrated with the same CJ-series

functionality and high-speed capabilities

Duct

Duct

90 mm high

S82K

G3J

J7AN

Power supply

SSR

Contactor

The same level of high-speed processing

Digital Controller

High-speed processing

(Example: 1-ms response)

High-speed processing

(Example: 50 ms)

SYSMAC CJ-series PLC

Dedicated microcomputer board

PCMIX Values

CJ1G

SYSMAC

7.4

1.4

Sequencing

Only One CPU Unit Needed

Greatly

reduces space

between ducts

Note: Loop configuration: Ai4 Terminal + Segment Linearizer + Basic PID + Ao4 Terminal

The external I/O response time in the overall system refers to the conversion time.

Ultra-small size fits in most

devices

Backplane-free structure provides

the functions you need in

minimum space.

Low-cost solution for controlling

multiple loops

Control functions have the added

ability to control multiple loops.

Consolidating the proven CS-

series loop-control technology

Effective maintenance functions

Function block programming for

easy engineering

Seamless integration of sequence

control and loop control.

HMI windows can be simply

generated from function blocks

automatically.

Super compact: Only 90 mm High and 65 mm Deep, and

Backplane-free structure enables flexible width design.

High-speed sequence control functions can be used directly for

high-speed, advanced loop control.

Compact PLC Aids Machine Downsizing by Fitting Just About Anywhere.

Wide Array of I/O Units, Special I/O Units, and CPU Bus Units Are Available to Suit Your Application.

Sequence control: Executes 20-Kstep ladder programs in 1 ms (with basic instructions only).

PCMIX = 7.4 LD or OUT executed in 40 ns

Loop control: Executes PID operations for 20 loops in up to 10 ms. This is a guide for general

applications.

(See note.)

Integrated Loop Control and Sequence Control

Sequence Control Engine

Loop Control Engine

An engine for controlling analog quantities (e.g., temperature, pressure, flowrate) is built into the CPU Unit together

with the engine for executing sequence control, delivering high-speed sequence control and high-speed, advanced

analog quantity control in a single Unit.

CPU Unit element:

CJ1G-CPU4 H

69 mm

D: 65 mm

90 mm

Loop-control

CPU Unit

2

CX-Programmer sequence control program

(ladder, function block, structured text)

Loop Controller Element:

Up to 300 or 50 function blocks

CX-Process loop control program (function blocks)

20-Kstep

1 ms

Execute

20-Kstep

ladder

programs in

1 ms

(See note.)

Note: Basic instructions only

20 Loops in 10 ms

Execute PID Control for

20 Loops

10 ms

(See note.)

Note: General application (e.g., loop

configuration: Ai4 Terminal + Segment

Linearizer + Basic PID + Ao4 Terminal)