Raypak XPAK 85 User Manual

Page 67

67

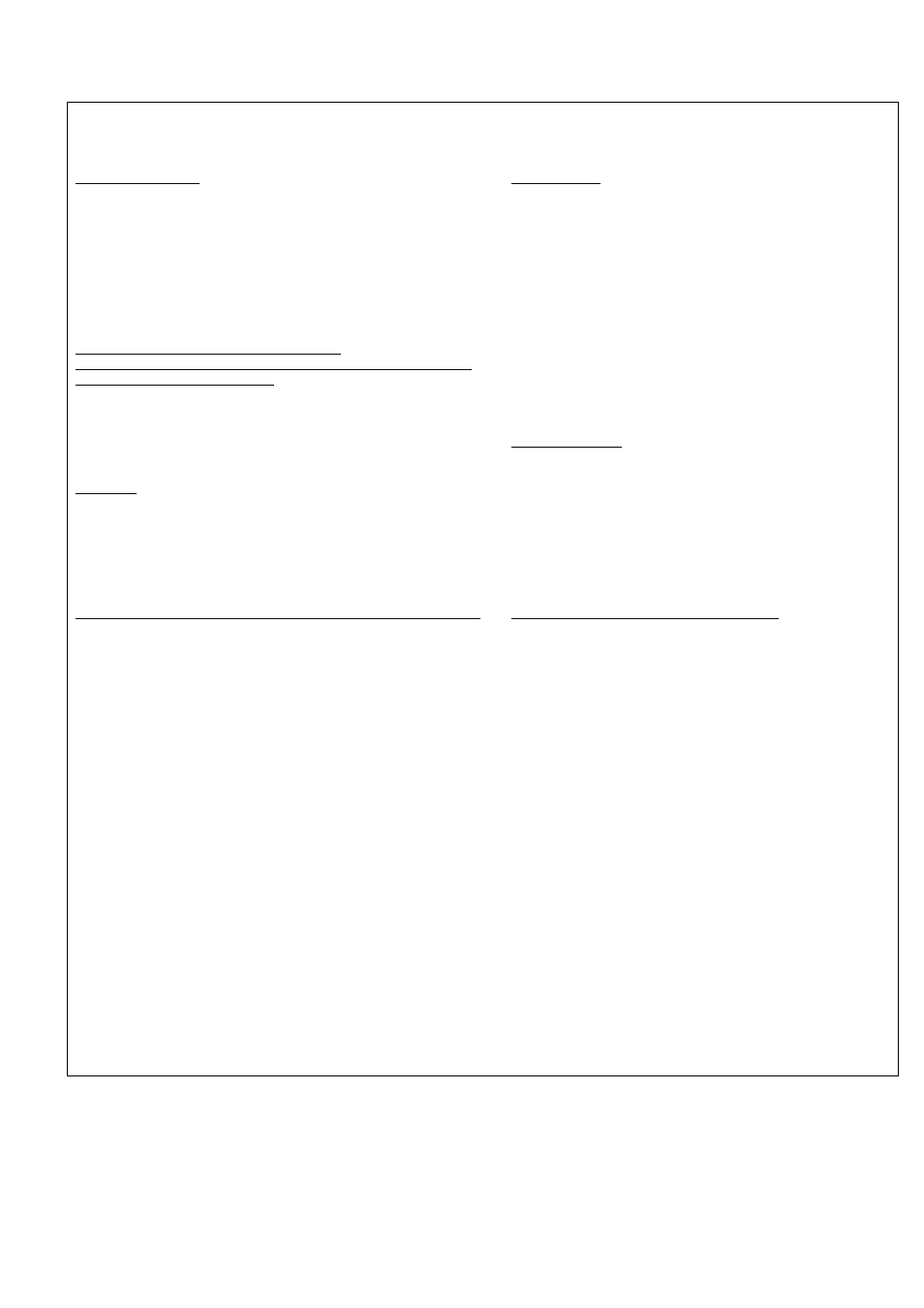

START-UP CHECKLIST FOR FAN-ASSISTED

RAYPAK PRODUCTS

This start-up checklist is to be completely filled out by the service technician starting up the Raypak Boiler for the first time. All

information may be used for warranty purposes and to ensure that the installation is correct. Additionally this form will be used to

record all equipment operation functions and required settings.

GAS SUPPLY DATA

CLEARANCES

Regulator Model & Size

_________ /

CFH

Front Clearance

_______________In.

Gas Line Size (in room)

____________

In. NPT

Right Side Clearance

_______________In.

Length of Gas Line

____________

Eq Ft

Left Side Clearance

_______________In.

Gas Shut-Off Valve Type

____________

Rear Clearance

_______________In.

( Ball, Lube cock)

Overhead Clearance

_______________In.

Sediment Trap

____________

Y/N

Port

_______Std__

Full

ELECTRICAL

Voltage Supply (VAC)

No Load______ Load_____

Voltage -24 VAC

_____________ VAC

Voltage Com to Ground _____________ VAC

VISUAL INSPECTION OF COMPONENTS

Operating Control Setting _____________deg F

Verify inspection was done and condition of components are in

good working order with a “yes”

Wiring Harness

_____________ Y/N

Burner/s (flame)

_____________ Y/N

Remote flame sense

_____________ Y/N

Sketch plumbing on reverse side

WATER SUPPLY

Flow Rate in GPM or Delta T __________ If Avail

Measure flow rate at full fire

VENTING

Number of Tanks and Size Qty____ ____ Gallons

Vent Size:___________

Stack Height:_____

Plumbing Size

_______________

Category: _________

sketch vent on reverse side ***

Pump Size: _________ (boiler)

Pump HP: ________

Vent Material:

__________________

Impeller trim____________

Pump Model________

Vent Termination Type:

__________________

Louvers __________________

Screens____________

Combustion Air Openings:

Low __________in2

Ventilation air

High _________ in2

EMISSIONS SETTINGS AND TEST INFORMATION (AT FULL FIRE)

Nominal Factory Recommended Settings

Blower Pressure Setting

______________ In. WC

See manual or card tag

Supply Gas Pressure

______________ In. WC

See manual or card tag

Verify stable pressure static & dynamic condition

Manifold Gas Pressure

_____________ In. WC

See manual or card tag

Tracking Pressure (clean filter) ______________In. WC

The following measurements must be obtained with a Combustion Analyzer.

NOX

_____________ PPM

Less than 20 PPM (If required by Certifying Agency)

Free Oxygen

_____________ %

See manual

CO

_____________ PPM

Less than 170 PPM

CO2

_____________ %

See manual

Model Number: ______________________________

Serial Number: _______________________________

*** Note: draw venting with details, such as extractors,

Site Altitude Above Sea Level __________________Ft.

barometric dampers, blast dampers or draft inducers

Job Name _______________________________________________________________________________________

Address _________________________________________________________________________________________

Physical Location of Boiler: Indoors______; Outdoors______; Ground Level______; Roof______; Below Grade______

Mechanical Contractor / Installer _______________________________________________________________________

Date and Time of Start-up _____________Print Name and Signature of Start-up Technician_________________________

Information must be faxed to: (805) 278-5471 in order to ensure warranty consideration Attn: Service Manager