Raypak XPAK 85 User Manual

Page 37

37

12. OUTDOOR SENSOR CONNECTION

The user can program the desired supply temperature based on

the outdoor temperature. Once the outdoor sensor is connected

to the control board, the water temperature of the boiler will adjust

to run the boiler more efficiently and provide greater comfort to the

living space.

Connection Specification – Wire 22 AWG maximum to 100 ft (30 m).

Outdoor Sensor is connected in the junction box on the XPak.

Route wires from the terminal strip to your outdoor sensor, which

will allow the user to change the temperature going to the Central

Heating loop automatically. Place the outdoor sensor preferably

to the north or northwest or to the side which will be affected by

changing weather conditions outside. NOTE: Do not locate the

sensor in the direct sunlight.

14. REMOTE CONTROL CONNECTION

The boiler can be fully remoted using an open therm plus remote

control (use only Raypak REC 08 Part No 013073).

When the control is installed with the boiler display shows as per

Fig. 36. No operation can be made on the boiler control panel

once the remote control is installed.

All the boiler settings can be made only by Remote Control once

it is connected.

See Remote Control instruction for setting and use.

Fig. 36

Fig. 37

Fig. 38

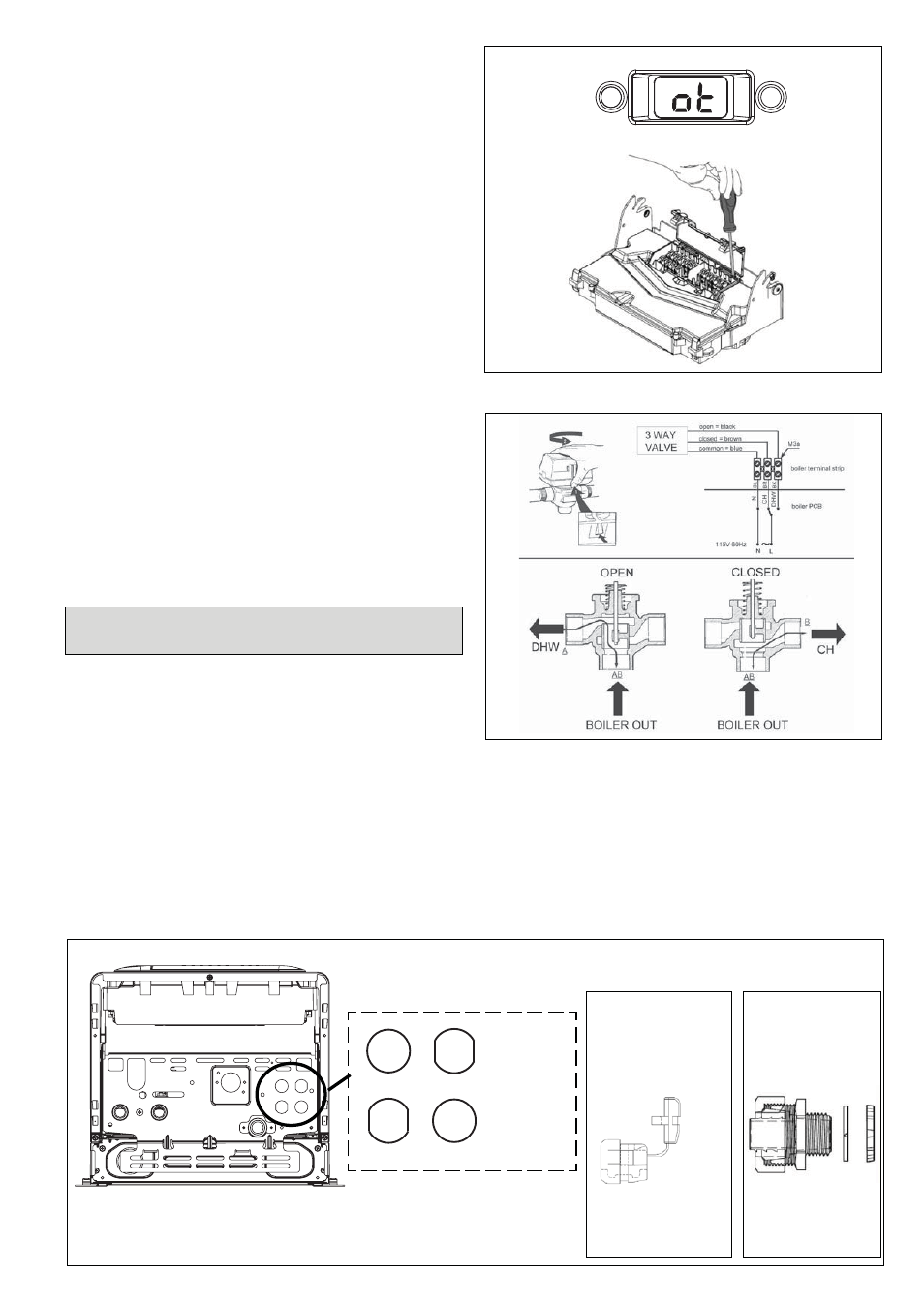

13. 3-WAY VALVE WIRING CONNECTION

XPak boiler can manage an external 3-way valve (field supplied),

the terminal strip (M3a) output is 120V – 60 Hz (see electric

diagram).

Logic of the boiler managing 3-way valve

1.

Boiler configuration in DHW (case A and case B), see Fig. 61

for boiler jumper configuration.

2.

Once the jumper has set in DHW mode (tank with probe or

tank with thermostat), when there is a heat request from the

sensor or from the thermostat, there is power out (120V – 60

Hz) to the boiler terminal strip M3a (Fig. 35).

3.

The output to the 3-way valve DHW pin is continuously supply

up to the heat is satisfied.

4.

The room thermostat request is independent from the DHW

request (Priority is always given to DHW production).

5.

The 3-way valve is always powered, even if there is no DHW

demand.

WARNING:

The 3-way valve is continuously powered even

if there is no heat request from the tank.

Wiring connections 3-way valve

Suggested source: Honeywell VC6011 (actuator) + VCZMK6000

Wiring the valve as per diagram Fig. 38.

Follow the installation of the piping referring to the diagram

showing the logic of working Fig. 38.

The connections colors and schematic refer to the Honeywell

VC6011 (actuator) + VCZMK6000.

Choose one of the two options for the strain relief that XPak allows

Main supply

cable

3 way valve

cable

1

Straight-Thru:

Heyco HFC-Z 1/2

Listed under UL

File #E-206446

2

Strain Relief

Bushings:

Heyco SR 7K-2

Listed under UL File

#E-15331 CSA

LR8919

2

2

1

1

Fig. 39