Electrical – Nortec 132-3091 User Manual

Page 7

has been improved to prevent backup despite long

or gently sloped drain lines but it can not

compensate for flat or uphill runs.

2.

The drain line should not end in a sink used

frequently by personnel, or where plumbing codes

prohibit it. Route to a floor drain or equivalent for

safety reasons, since drain water from humidifier

can be very hot.

3.

Keep drain lines as short as possible. Keep drain

lines sloped down, not level and not up since

low spots in drain lines will accumulate

sediment and cause backup. The drain line

should be 7/8" O.D. copper pipe or larger. Do not

use plastic pipe for drain lines. Consult factory.

STEAM LINE AND CONDENSATE RETURN LINE

1.

Refer to the installation manual of the steam

distribution system used in your application.

Steam Distribution - Form #XX-231, SAM-e - Form

#XX-249, Blower Pack - Form #XX-239.

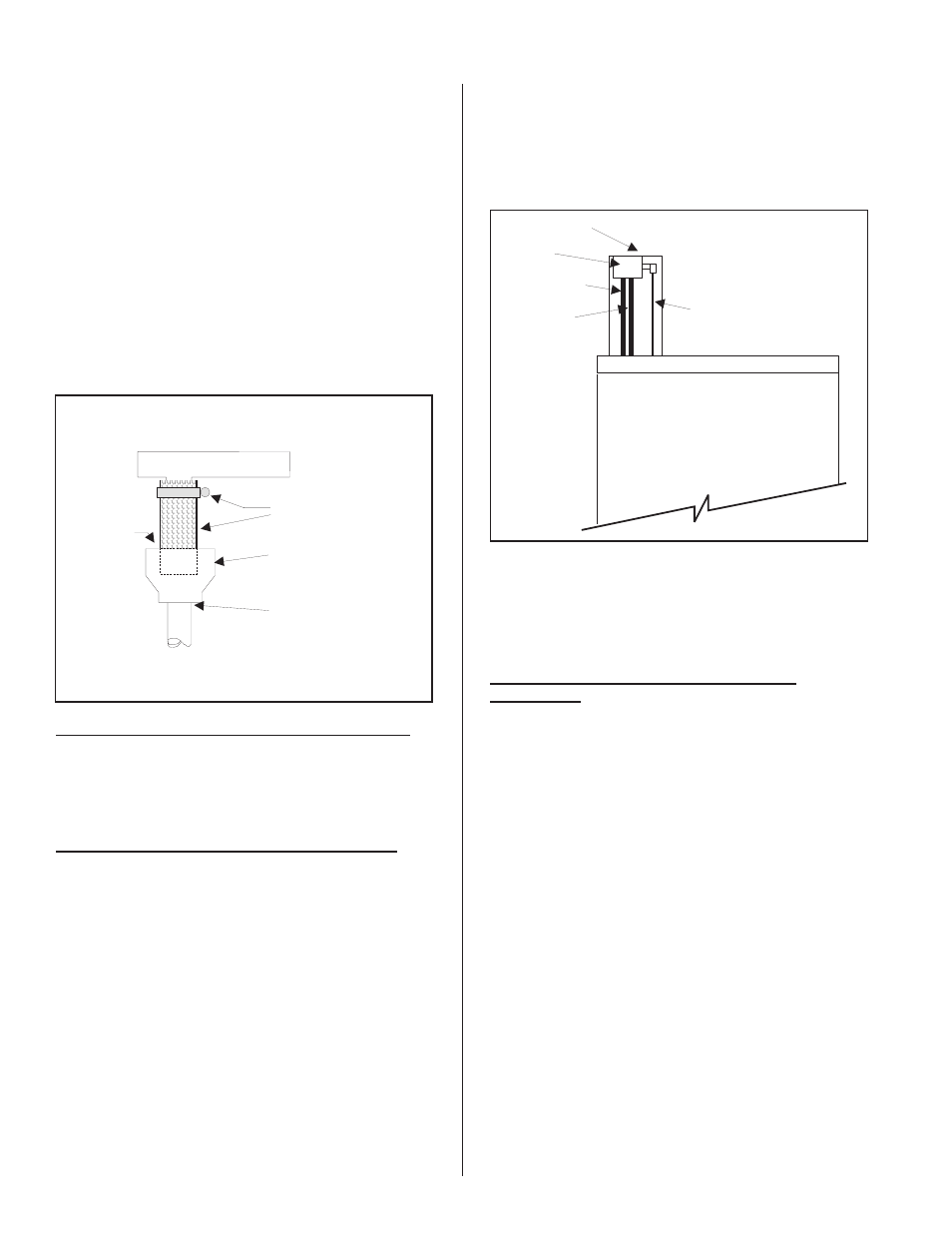

ACCESSORIES - FILL CUP EXTENSION KIT(S)

1.

The NH Series humidifier is an electrode

humidifier. It produces steam at atmospheric

pressure. Pressure head must develop to push

steam through supply line and into air duct.

2.

Combined resistance of duct positive static

pressure and steam line resistance creates a

small pressure head in steam cylinder. Total

amount of positive static pressure head is

reflected directly by water column differential that

develops between water in the fill cup hose

feeding cylinder and water level in cylinder.

3.

Standard dimensions of humidifier limit static that

can be tolerated before water will be pushed high

enough to spill over into overflow tube in fill cup

assembly.

4.

To increase allowable water column (allowable

positive static pressure) an accessory Fill Cup

Extension Kit is available from NORTEC. See

Figure #8.

5.

Water column requirements are even higher duct

static pressure when distributor’s steam outlets

are faced with downflow duct applications.

ELECTRICAL

PRIMARY VOLTAGE SUPPLY WIRING TO

HUMIDIFIER

1.

Check and ensure that available voltage and

phase corresponds with operating voltage and

phase of humidifier as indicated on the humidifier

nameplate label (see Figure #1).

2.

Ensure that an adequate power supply is available

to carry full humidifier amperage drawn as

specified by rated amps on the humidifier

nameplate label refer to local codes.

3.

A dedicated external disconnect must be installed.

Do not exceed the maximum circuit protection

amps as indicated on the nameplate label.

4.

Optional internal primary fuses are not intended to

substitute for external fuses. Internal primary

fuses are a factory added option (when specified)

to protect internal primary wires individually.

5.

Connect ground wire to cabinet ground clamp. Do

not use neutral wire of four wire supply as ground.

6.

Single phase humidifiers may be run on three

phase power, but load may unbalance power grid.

7.

External wiring sizes must be in accordance with

NEC and/or CEC and existing local electrical

codes and by-laws.

- 4 -

ClampAnd

1.5” I.D. Hose

Factory Supplied

2" O.D. StainlessSteel Pipe

Or 2" I.D.DI Compatible Hose

(Not Supplied)

Stainless steel Reducer To

ServeAs Funnel

Drain (By Others)

Air Gap

NOTE: Steam hose should not reach bottom of the funnel.

Figure #7

Drain Connection

Hose From Fill Valve

Fill Cup Bracket

Fill Cup

Overflow Hose

Fill Hose To

Cylinder

Figure #8

Fill Cup Extension Kit to Overcome Static Pressure