Low volt age con trol wiring 5, On-off con trols 5, Con trol in stal la tion 5 – Nortec 132-3091 User Manual

Page 14: Low voltage control wiring, On-off controls, Control installation

dependent on water supply conditions and humidifier

usage. Failure to replace the cylinder at the end of

cylinder life may result in unit damage. NORTEC is

not responsible for any damages resulting from, or

attributable to, the failure to replace a used cylinder

(see Manufacturer’s Warranty). There are many

indications, each of which signifies the end of cylinder

life.

NHMC

1.

After a period of operation (not on initial start-up),

the water level will approach the top of the

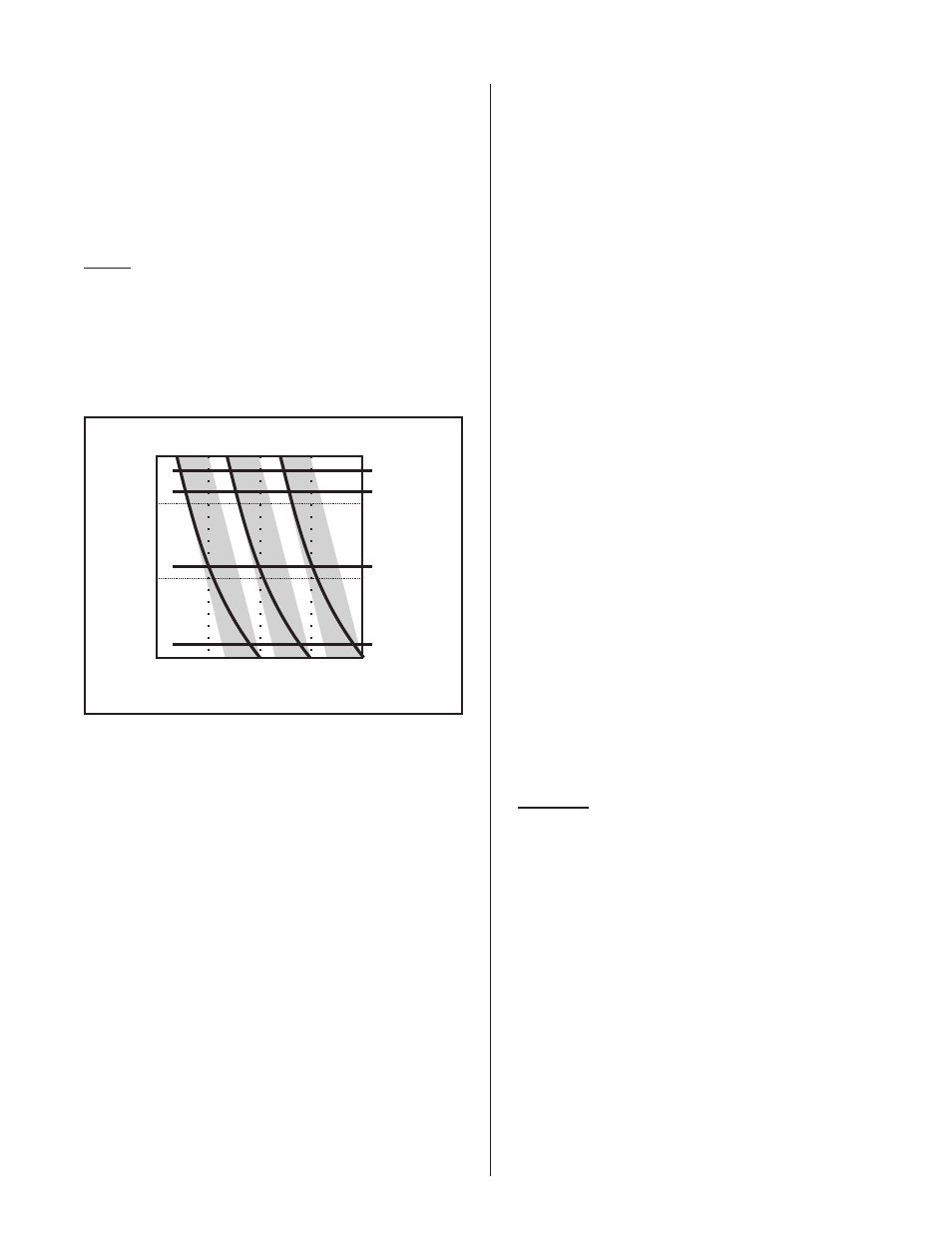

cylinder. (Life varies from 500 to 2000 operating

hours, as illustrated in Figure #12.)

2.

There will be reduced output in spite of a 100%

capacity setting and/or an unsatisfied demand

from the humidistat for more humidity. This is

evident by monitoring the unit’s output on the LCD

(liquid crystal display) with up to two lines of

continually updated alphanumeric information for

the user.

3.

Each NHMC humidifier has an internal

micro-computer that can detect end of cylinder life.

If the cylinder is not changed, the humidifier will

automatically shut down.

4.

The unit’s yellow status lamp is activated anytime

there is a system message sent to the LCD where

two lines of alphanumeric information await the

user. System messages are explained in greater

detail later in this manual. Three (3) different

messages will appear, in sequence, as the

cylinder goes from new to spent to needing

replacement.

5.

The NHMC is pre-programmed to inform the user

of the cylinder’s status. It is important to

understand the significance of the unit’s system

messages, status lamps and 24VAC circuits for

remote indication. Figure #2 summarizes these

messages and responses.

6.

The three (3) messages that will appear in

sequence are “MAXIMAL LEVEL”, then

“CYLINDER SPENT”, and finally “CYL. LIFESPAN

END”. The yellow unit status lamp will be on

during all three.

7.

The green unit status lamp, primary contactor and

steam output will stop at “CYL. LIFESPAN END”.

This distinguishes it from “MAXIMAL LEVEL” and

“CYLINDER SPENT”.

8.

Each of these three (3) messages has a unique

combination of responses at the terminal strip for

remote indication. These unique combinations

distinguish them from each other and from any

other system message.

9.

At “MAXIMAL LEVEL” remote yellow-green-red

are OFF-ON-OFF. (Note that “MAXIMAL LEVEL”

will also appear at unit start-up.)

10.

At “CYLINDER SPENT” remote yellow-green-red

are OFF-ON-ON. In other words, the red comes

on as the cylinder ages from “MAXIMAL LEVEL”

to “CYLINDER SPENT”. This gives the user

ample warning (remote red on) to replace the

cylinder before the NHMC shuts itself down.

11.

At “CYL. LIFESPAN END” remote

yellow-green-red are ON-OFF-ON. In other

words, the remote green goes off and the remote

yellow comes on in addition to the red if

“CYLINDER SPENT” remains unchanged for

approximately three (3) days.

12.

The NHMC is always internally wired to provide

24VAC to the terminal strip for optional external

remote indication. Up to 100 mA is available at

each of three terminal pairs (61-20, 62-40 and

63-36) for activating yellow, green and red optional

external remote indicators, respectively. Any or all

of these remote indicators can be utilized. They

can be field-supplied resistive 24 VAC loads such

as lamps or ordered as options from NORTEC.

NHB/NHP

1.

There will be reduced output in spite of a 100%

capacity setting and/or an unsatisfied call from the

on/off humidistat for more humidity. The NHP has

an output display where you will observe that the

capacity of the unit is decreasing.

2.

Each NHB/NHP humidifier has a yellow status

lamp, a green status lamp, and a relay for remote

indication. Double units (models NH 150-200)

have two of each.

3.

The yellow and green status lamps are long-life

LED’s (light emitting diodes) not incandescent

lamps.

4.

The yellow and green status lamps are to be

viewed as a pair. This way, they convey four

- 11 -

Grains

of

Hardness

Capacity Adjustment Setting

Cylinder Life Expectancy

(average operating hours)

30

20

10

5

100%

50%

25%

500

400

200

100

500

1000

2000

4000

8000

CaCO

mg/L

(ppm)

3

Figure #12

Water Conditions vs. Cylinder Life