Steam dis trib u tors 3, Steam distributors, Plumbing – Nortec 132-3091 User Manual

Page 6

safety thermostat to turn off the humidifier if the

blower pack gets overheated. Control thermostat,

mounted on the steam distributor, starts the fan

when steam is generated. When supply voltage

differs from voltage required to run blower motor,

blower pack will contain a proper transformer. All

blower packs provide intake air filters.

For installation details about the blower pack,

please refer to the blower pack installation manual

located in the blower pack box (Form #XX-239).

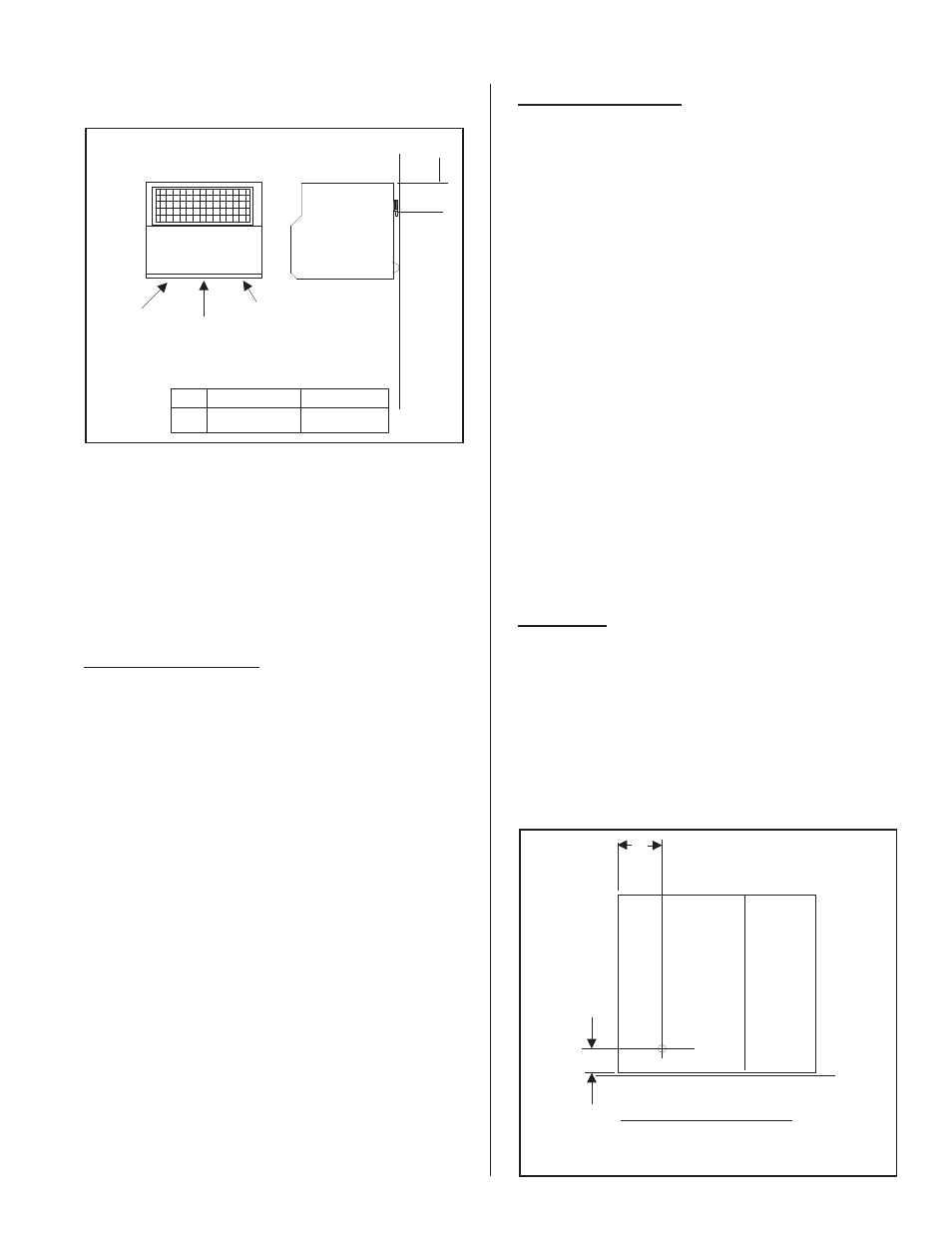

STEAM DISTRIBUTORS

1.

Steam distributors are used in ducts or air

handling units, and are made of stainless steel.

2.

Steam distributors can be in vertical or downflow

applications.

3.

Proper location should consider: air temperature,

relative humidity before the distributor, air velocity,

dimensions of the location, amount of steam

introduced into the duct, downstream obstructions,

and surfaces vulnerable.

4.

For installation details, please refer to steam

distributor installation manual located in the

distributor box (Form #XX-231).

5.

For calculating absorption distances, refer to

H.E.L.P. Software or steam distribution and

absorption distances engineering manul (Form

#XX-232).

PLUMBING

All water supply and drain line connections

should be installed in accordance with local

plumbing codes.

WATER SUPPLY LINE

1.

Humidifier is intended to operate on potable (cold)

tap water.

2.

If the raw water is very hard, NORTEC can

provide longer cylinder life on softened water.

However, softened water is more conductive and

more corrosive. Some hardware and/or software

changes may be required, at time of order or in the

field. Consult factory.

3.

If RO or DI is available, blending may increase

cylinder life. Consult factory.

4.

DO NOT use a hot water supply to humidifier.

Minerals will adhere more easily to surfaces and

the fill valve’s small flow regulating orifice and

could become plugged.

5.

Standard fill valves are sized for water pressure

ranging from 30 to 80 psig (ideally 55 to 60 psig).

For other pressures, consult factory. This

pressure should be measured at the humidifier if

the water pressure is suspect.

6.

ALWAYS supply and install a shut off valve in the

water supply line dedicated to the humidifier to

facilitate servicing. Use ½" OD copper to within 4

feet of the humidifier. Reduce copper to 3/8" OD

and connect to the factory-supplied 3/8" olive

compression fitting under the humidifier.

DRAIN LINE

1.

Humidifier is equipped with a 7/8" O.D. unthreaded

drain outlet on underside of drain canal on bottom

of the humidifier (see Figure #6). A field-supplied

funnel (see Figure #7) is recommended. It will

prevent backup in the drain pan and in the cylinder

due to partially blocked or badly installed drain

lines. This prevents rusting of the drain pan and

arcing due to over-concentration. The drain canal

- 3 -

005-030

3.2" (8.0cm)

050-100

3.2" (8.0cm)

A

Front

Wall

Side

Steam

Condensate

A

Power and control

wiring from humidifier

Figure #5

Remote Mounted Blower Packs (RMBP)

Bottom View

Wall

B

A

Model

005 - 030

050 - 100

150 - 200 Left

150 - 200 Right

B in.(mm)

19.6 (498)

Ain.(mm)

1.0 (25)

2.2 (55)

2.2 (55)

2.2 (55)

6.2 (158)

6.2 (158)

5.0 (127)

Figure #6

Drain Line Connection