Nhmc operation – Nortec 132-3091 User Manual

Page 11

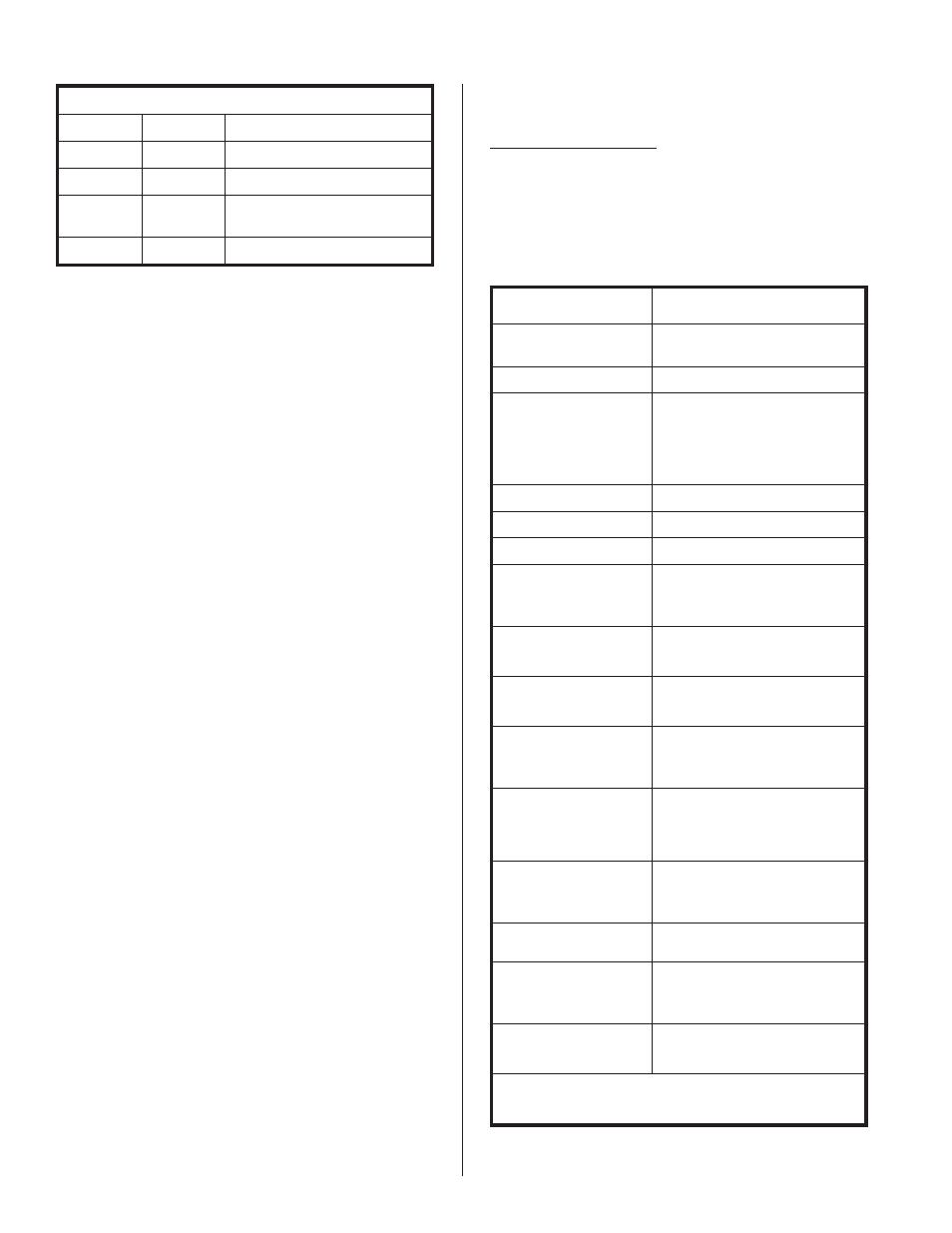

SIGNAL LIGHT STATUS

YELLOW GREEN

OFF

OFF

Off

OFF

ON

Normal operation

ON

ON

Replace cylinder or normal

startup operation

ON

OFF

Operation fault

The prerequisites for getting power and water into

the steam cylinder are as follows:

- on/off/drain switch must be switched on

- control circuit 8-10 must be made

- modulation humidistat, if present, must be calling

- control circuit 82-83 must be made

- control circuit 84-85 must be made

- cabinet mounted humidistat, if present, must be

calling

- door interlock switch must be made (interlock switch

can be pulled out to operate unit)

Most water does not contain enough conductivity

for full boil on initial start-up. Units will need to

concentrate the water over a time period (hours to

days). During this process both lights are on.

NHMC OPERATION

START-UP SELF TEST

Observe the LCD display when the on/off/drain

switch is first pushed on. The microcomputer pc board

will check the system components, display in words

what it is doing and provide a message if any faults

are found. The start-up self-test sequence will be

displayed as follows:

LCD

EXPLANATION/COMMENTS

(WHAT YOU READ)

CONDAIRMATIC MC

Note the V number. It tells you

the EPROM version.

NORTEC V2...

CONDAIRMATIC MC

Note the model type. Ensure

NHMC (model type) compatibility

with spec label (name plate).

Can be reconfigured if

necessary.

SYSTEM TEST

Test begins.

LAMP GREEN

Observe green signal light on

LAMP YELLOW

Observe yellow signal light on

CONTACT RELAY 1

Provides 24 VAC to 61-20 and

external optional yellow lamp at

control strip to simulate a fault.

DRAIN VALVE

Observe 24 volt solenoid

activated on drain valve.

INLET VALVE

Observe 24 volt solenoid

activated on fill valve.

CONTACTOR

Observe 24 volt coil activated

on contactor OR fan activated on

blower pack if present.

CONTACT RELAY 2

Provides 24 VAC to 63-36 and

external optional red lamp at

control strip to simulate cylinder

spent.

CONTACT RELAY 3

Provides 24 VAC to 62-40 and

external optional green lamp at

control strip.

INTERNAL TEST

Completion of self test.

LAMP

GREEN-YELLOW

INTERNAL TEST

Observe green and yellow

lamps pulse on together as sign

that all passed.

STEAM OUTPUT

INTERNAL TEST

Begins normal operation and

displays lbs/hr.

NOTE: If cylinder water reaches the full cylinder

sensor, the LCD will read “MAXIMAL LEVEL”.

- 8 -