Nortec 132-3091 User Manual

Page 23

2. Max. Filling Time

Symptom(s) Diagnosed: The fill valve has been

“on” for a longer time than is normally required for

non-zero current to flow between the electrodes or

for water level in the cylinder to reach the high

water sensor pin.

Probable Cause(s): Blocked drain due to blocked

cylinder strainer or blocked drain valve preventing

water from entering the cylinder. Drain valve

leaking due to dirt in seal or powered by defective

main PC board or powered by wiring error. High

water sensor circuit not responding due to sensor

plug not connected or defective high water sensor

PC board or wiring error or defective main PC

board. Water supply rate too low or zero due to

too low pressure or line restriction or clogged

built-in strainer. Too low supply water

conductivity. DI (de-ionized) or RO (reverse

osmosis) supply water has almost no conductivity.

Measure conductivity and report findings to factory

if suspected.

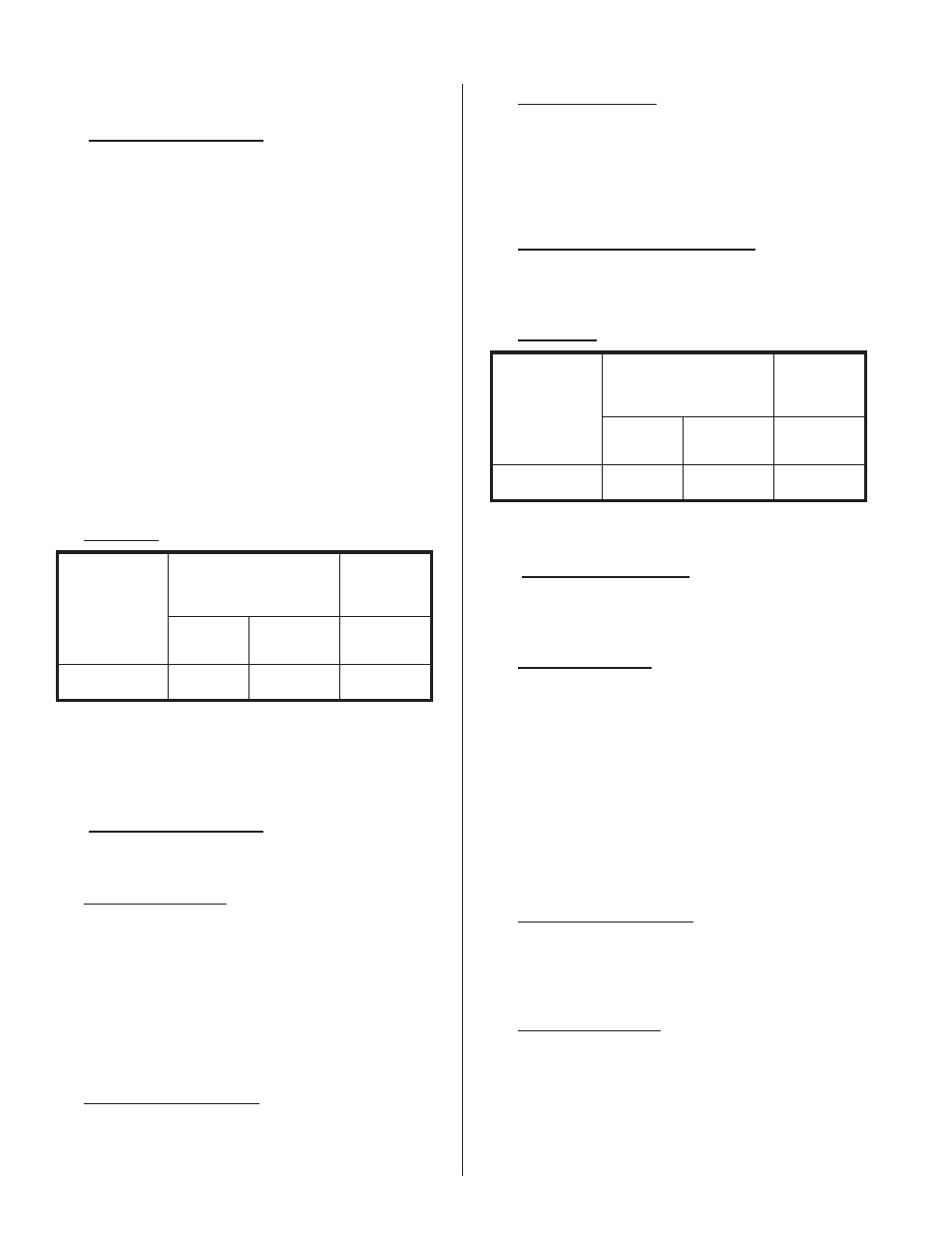

Response:

UNIT STATUS LAMPS

REMOTE

INDICATION

(24 Vac to:)

UNIT

CONTACTOR

YELLOW

GREEN

61-20

“YELLOW”

OFF

ON

OFF

ON

NHB Explanation of Symptoms Without Automatic

Shutdown

4. No Current But High Water Sensor On

Symptom(s) Diagnosed: High water level in the

steam cylinder is detected, yet no current is

detected in the steam cylinder.

Probable Cause(s): Sensor plug connected to

wrong cylinder pin. High water sensor PC board

defective (activates with no water). Main PC

board defective (activates high water circuit

without sensor PC board). Monitored leg of three

phase power supply is dead. Main PC board

defective (does not sense current when current is

present in monitored leg).

5. Cylinder Spent

Symptom(s) Diagnosed: The high water sensor

circuit is activated. Other criteria are used to

distinguish cylinder spent from normal startup and

diagnose the steam cylinder as spent, as

previously described.

Probable Cause(s): As pure steam is produced

from tap water, most minerals are drained by the

auto-adaptive control system. However, it is

inevitable that minerals will buildup on the

electrodes and strainer inside the steam cylinder.

It is unavoidable and the cylinder is intended to be

disposable.

Unit Takes Self-Corrective Action: The humidifier

continues to operate with gradually decreasing

capacity, giving the user notice by responding as

shown below.

Response :

UNIT STATUS LAMPS

REMOTE

INDICATION

(24 Vac to:)

UNIT

CONTACTOR

YELLOW

GREEN

61-20

“YELLOW”

ON

ON

ON

ON

6. No Current But Humidistat Calling

Symptom(s) Diagnosed: For a few minutes, no

current is detected in the steam cylinder, despite a

demand for humidity. (Current is not expected to

be zero when there is a demand for humidity.)

Probable Cause(s): Drain valve is leaking, so

water never reaches the electrodes. Water supply

is obstructed. Contactor is not activated. Supply

water is “pure” without conductivity. Fill valve is

blocked. Fill valve is not being activated. Supply

water pressure is too low (less than 30 psig).

Wrong orifice in fill valve. High duct static

pressure blows back into the fill cup (via the steam

line and empty cylinder) diverting the fill water to

overflow. (Taking the steam hose off until some

water gets into the cylinder solves this.)

6. Output Too Low

Symptom(s) Diagnosed: For a few minutes,

current does not increase in the steam cylinder,

despite the fill valve being activated. (Current is

expected to increase soon after the fill valve is

activated.)

Probable Cause(s): Drain valve is partially open,

so fill rate maintains non-zero but non-increasing

current. Continual overflow because high water

sensor circuit did not respond to full cylinder.

Supply water insufficiently conductive. Fill valve is

partially restricted due to dirt, pinched supply line,

or wrong orifice. Steam supply line is obstructed

so back pressure causes continual overflow.

- 20 -