Op er a tion 7, In tro duc tion 7, Lay out and func tion 7 – Nortec 132-3091 User Manual

Page 16: Nhmc op er a tion 8, Start-up self test 8, Operation, Introduction, Layout and function, Nhmc operation start-up self test

messages, instead of two, as summarized in

Figure #14.

5.

When both the yellow and the green status lamps

are on, the water level is detected as being at the

top of the cylinder. This is normal on start-up, but

as the contained water concentrates, the water will

stabilize at a lower water level and the yellow lamp

will be off.

6.

When the cylinder is fully used, the water level will

have returned to the top of the cylinder. Since

there is no longer any clean electrode surface

available at end-of-cylinder-life, the required steam

output rate can no longer be maintained.

7.

At this stage, the yellow lamp flashes and the

green lamp is on, telling the user that the cylinder

is reaching the end of its life and will need to be

replaced shortly. The humidifier continues to

operate.

8.

The NHB relay for remote indication is not

intended to indicate end-of-cylinder-life. It is

intended to indicate other detected faults

explained later in this manual.

9.

The NHP at end of cylinder life will not operate,

the yellow lamp will “flash”, and the green lamp will

be “off”.

HOW TO REMOVE THE STEAM CYLINDER

1.

(It is advisable to keep a spare cylinder in stock

throughout the humidification season.) When

ordering a replacement steam cylinder, always

quote the three or five digit model number on the

label applied to the cylinder or quote the unit’s

serial number, model and voltage located on the

spec label (nameplate).

2.

Turn off water supply to unit.

3.

The used cylinder must be drained completely

before removal. If the water has just been boiling,

allow it to cool before draining. Push the

ON/OFF/DRAIN switch to the MANUAL DRAIN

position. Leave it in this position just long enough

to drain the cylinder (usually less than 10

minutes).

4.

When completely drained, push the main

ON/OFF/DRAIN switch back to the OFF position.

5.

Once drained, open the main electrical disconnect

during the entire cylinder change operation.

6.

Open plumbing door.

7.

Cylinder plugs are attached to the primary voltage

cylinder wires. (The plugs remain attached to the

wires unless they have to be replaced due to

damage.) The plugs are press-fitted over the

electrode pins protruding from the top of the

cylinder. Remove cylinder plugs from cylinder by

pulling vertically.

8.

Using slot screwdriver, loosen the steam hose

clamp(s) and pull steam hose off the cylinder

vertically.

9.

Using a small slotted screwdriver, depress tab on

the re-usable tie wrap, if present, around the

middle of the cylinder. This will loosen the tie

wrap to come apart for re-use later on.

10.

Cylinder is now ready to be lifted out of the unit.

CAUTION: Cylinder and any undrained water

might still be HOT.

MANDATORY CLEANING OF THE DRAIN

VALVE

Always clean the drain valve before installing a

new cylinder since the valve port may be as dirty as

the used cylinder.

1.

Remove used cylinder as previously described.

NORTEC does not recommend the use of any

acid solutions to clean the used cylinder. Always

replace a used cylinder.

2.

Note that ring terminal for drain valve green

ground wire is sandwiched between drain valve

body and drain pan.

3.

Remove two screws securing drain valve body to

drain pan. Disconnect the two slip-on terminals

from the two tabs on the (24VAC) drain valve coil.

4.

Remove hose clip and hose connection from drain

valve body.

5.

Drain valve assembly is now free to be taken to a

sink for disassembly and cleaning.

- 13 -

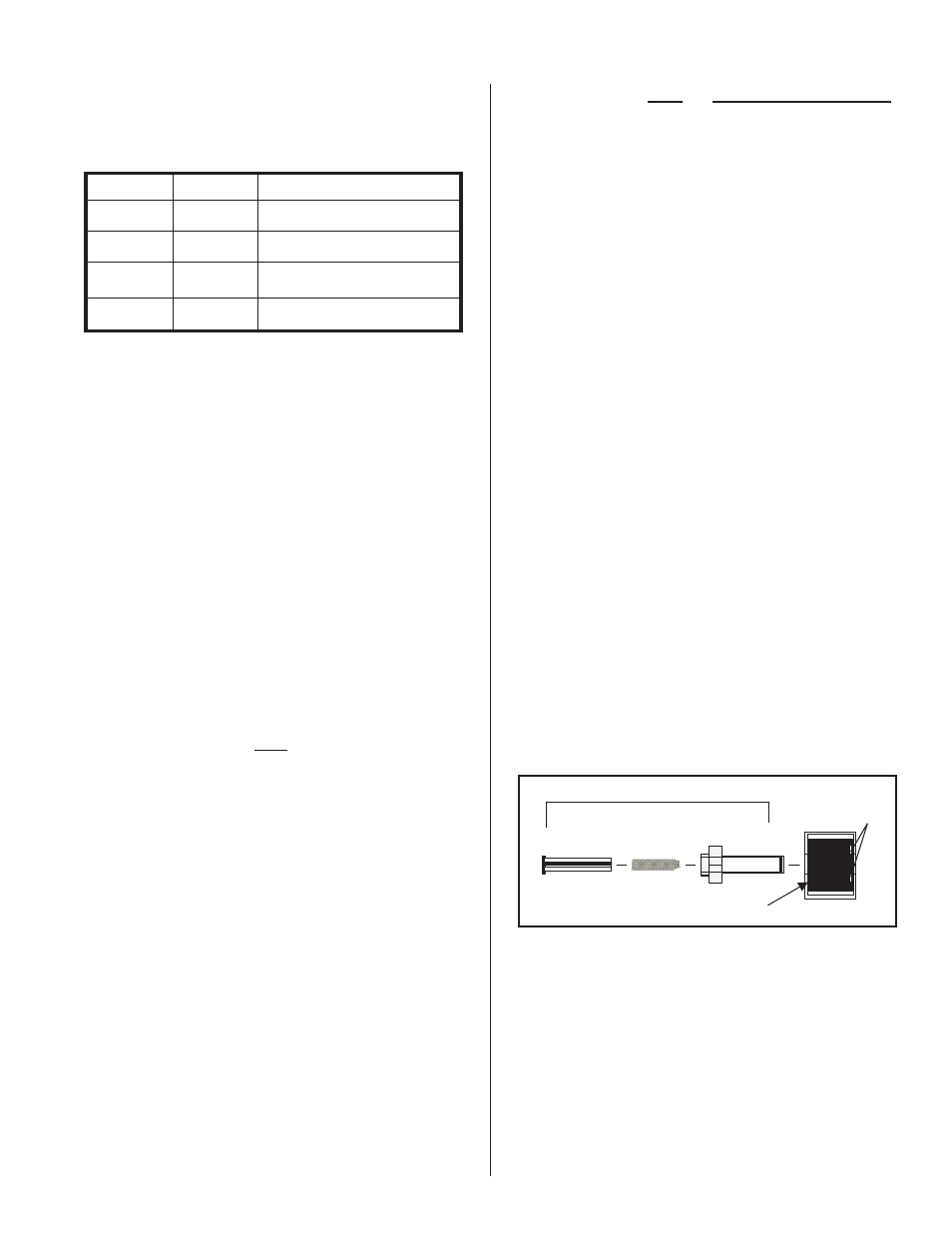

Plunger

Spring

Holding Coil

Sleeve

Male Slip-on

ConnectionTabs

Actuator

Figure #15

Reassembly of the Drain Valve and Fill Valve

YELLOW

GREEN

OFF

OFF

Off

OFF

ON

Normal operation

ON

ON

Replace cylinder or normal

start-up operation

ON

OFF

Operation fault

Figure #14