Panasonic ASCT1F46E User Manual

Page 11

10

1.Temperature,

humidity,

air pressure

During usage, storage, or transportation, avoid locations subject to direct sunlight and maintain normal

temperature, humidity, and pressure conditions.

The allowable specifications for environments suitable for usage, storage, and transportation are given

below.

1. Temperature: The allowable temperature range differs with each relay, so refer to the relay's

individual specifications. In addition, in the case of transporting and storing relays in a tube package, the

temperature may differ from the allowable range of the relay. So, please contact us for individual

specifications.

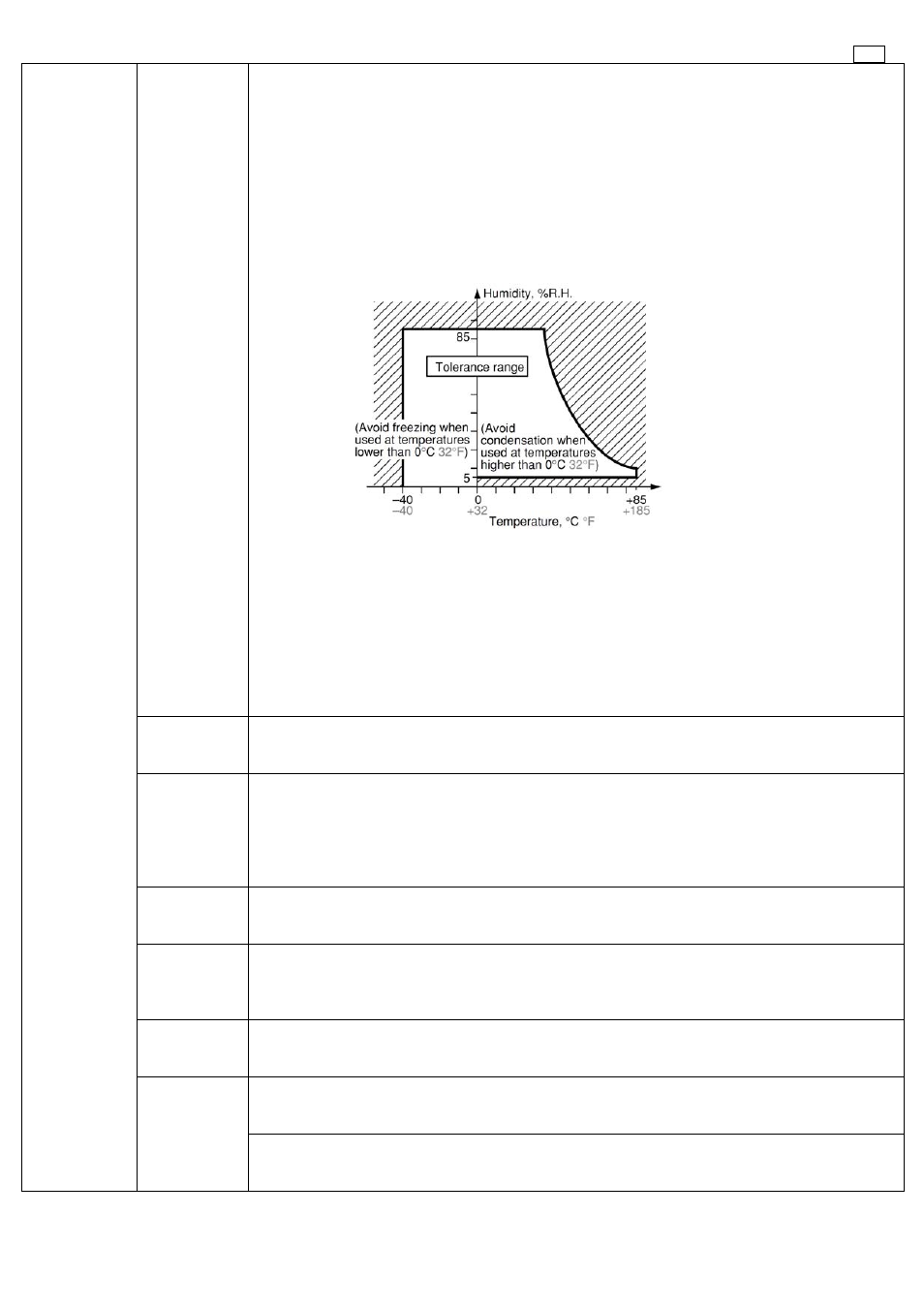

2. Humidity: 5 to 85 % R.H.

3. Pressure: 86 to 106 kPa

Furthermore, the humidity range varies with the temperature. So, use relays within the range indicated in

the graph below.

(The allowable temperature range differs for each relay.)

-Be sure the usage ambient temperature does not exceed the value listed in the catalog.

-When switching with a load which easily generates arc in high-humidity environment, the NO

x

generated by the arc and the water absorbed from outside the relay combine to produce nitric acid.

This corrodes the internal metal parts and adversely affects operation. Avoid using them at an ambient

humidity of 85%RH or higher (at 20°C). If it is unavoidable to use them in such environment, please

consult us.

-Plastic sealed type relays are especially not suited for use in environments which require airtight relays.

Although there is no problem if they are used at sea level, avoid using them in atmospheric pressures

beyond 96±10kPa. Also avoid using them in an atmosphere containing flammable or explosive gases.

2. Dust

It is recommendable to use relays in a normal temperature and humidity with less dust, sulfur gases

(SO

2

, H

2

S), and organic gases.

Sealed types (plastic sealed type) should be considered for applications in an adverse environment.

3. Silicon

Silicon-based substances (silicon rubber, silicon oil, silicon-based coating material, silicon caulking

compound, etc.) emit volatile silicon gas. Note that when silicon is used near relay, switching the

contacts in the presence of its gas causes silicon to adhere to the contacts and may result in contact

failure.

Therefore, please use a substitute that is not silicon-based. Plastic also has air permeability so please

avoid using them in a silicone atmosphere.

4. Magnetism

If relays are proximately installed each other or installed near highly-magnetized parts such as motor

and speaker, the relay may change its operational characteristics or cause malfunction. So, please

verify in actual installation and operational condition.

5. Vibration

Vibration of the area where relay is installed may be enhanced more than expected depending on

installation condition of PCB. So, please verify in actual use condition. NO contact is the recommended

contact for the use at the vibration-frequent area because the vibration resistance performance of NC

contact is generally inferior to that of NO contact.

6. Shock

It is ideal for mounting of relay that the movement of the contacts and movable parts is perpendicular to

the direction of vibration or shock. Especially note that the vibration and shock resistance of NC contacts

while the coil is not excited is greatly affected by the mounting direction of the relay.

Condensation forms when vapors when there is a sudden change in temperature under high

temperature, high humidity conditions. Note that condensation may cause deterioration of the insulation,

breaking of coil, and rusting.

12. Usage

ambient

condition

7. Dew

condensation

Note that if a relay is connected or installed with a high heat-capacity such as bas bar, connector,

harness, and PCB, heat removal phenomenon will accelerate cooling of the relay inside and promote

condensation. So, please verify in actual installation condition.