Troubleshooting, Caution, Power source- weld controller – Lincoln Electric POWER WAVE 11124 User Manual

Page 64

E-13

TROUBLESHOOTING

E-13

POWER WAVE® AC/DC 1000

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

Observe all Safety Guidelines detailed throughout this manual

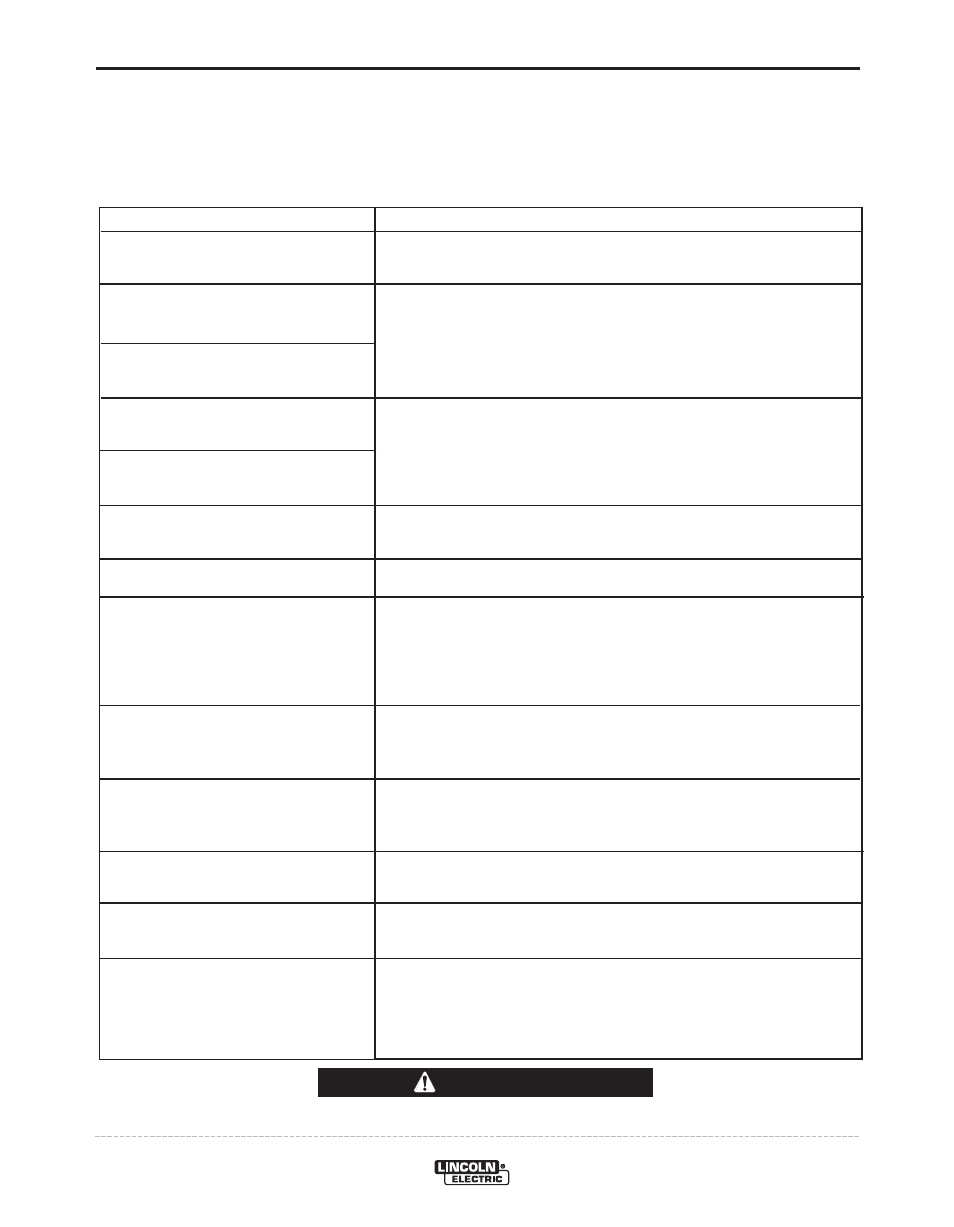

ERROR CODES

The following is a partial list of possible error codes for the Power Wave AC/DC 1000. For a complete listing con-

sult the Service Manual for this machine.

Error Code #

31 Primary (Input) overcurrent error.

32 Capacitor "A" under voltage (Left

side facing machine)

33 Capacitor "B" under voltage (Right

side facing machine)

34 Capacitor "A" over voltage (Left

side facing machine)

35 Capacitor "B" over voltage (Right

side facing machine)

36 Thermal error

37 Soft start error

41 Secondary (Output) overcurrent error

43 Capacitor delta error

46 Secondary (Output) overcurrent error

49 Single phase error

54 Secondary (Output) overcurrent error

Other

Indication

Excessive Primary current present. May be related to a switch board or output

rectifier failure.

Low voltage on the main capacitors. May be caused by improper input configu-

ration, or an open/short circuit in the primary side of the machine.

Excess voltage on the main capacitors. May be caused by improper input con-

figuration, , excessive line voltage, or improper capacitor balance (see Error

43)

Indicates over temperature. Usually accompanied by Thermal LED. Check fan

operation. Be sure process does not exceed duty cycle limit of the machine.

Capacitor pre-charge failed. Usually accompanied by codes 32-35.

The long term average secondary (weld) current limit has been exceeded.

This error will cause the machine output to phase back to 100 amps, typi-

cally resulting in a condition referred to as “noodle welding”.

NOTE: The long term average secondary current limit is 1050 amps.

The maximum voltage difference between the main capacitors has been

exceeded. May be accompanied by errors 32-35. May be caused by an open

or short in the primary or secondary circuit(s).

Absolute maximum output level has been exceeded. Usually associated with

excessive short circuit currents and/or specific weld mode issues. This is a

short term average designed to protect the inverter switching circuitry.

Indicates machine is running on single phase input power. Usually caused by

the loss of the middle leg of the input power (L2).

The long term average secondary (weld) current limit has been exceeded.

This error will immediately turn off the machine output.

Error codes that contain three or four digits are defined as fatal errors. These

codes generally indicate internal errors on the Power Source Control Board. If

cycling the input power on the machine does not clear the error, contact the

Service Department.

POWER SOURCE- WELD CONTROLLER