Installation, Recommended equipment – Lincoln Electric POWER WAVE 11124 User Manual

Page 15

A-5

INSTALLATION

A-5

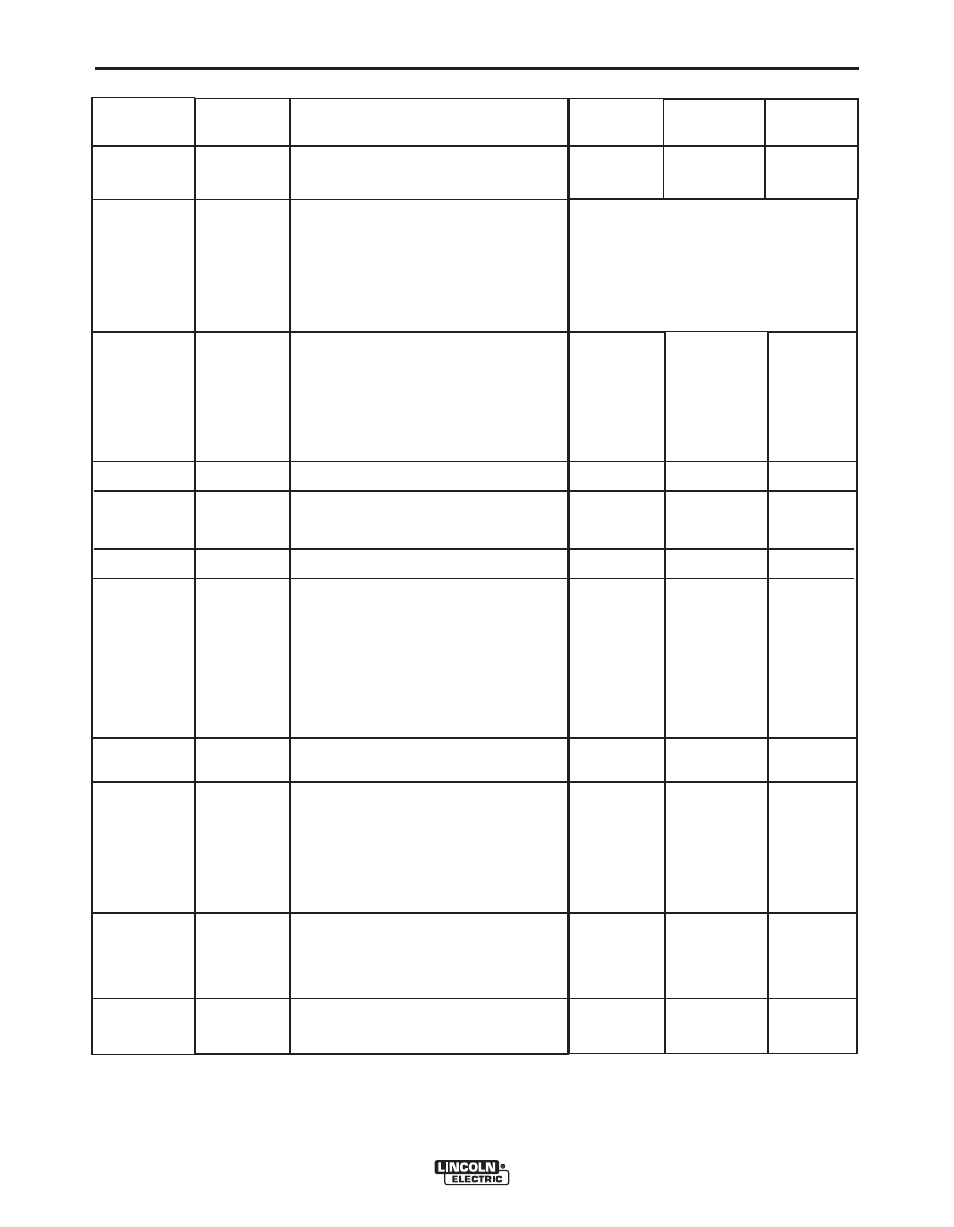

RECOMMENDED EQUIPMENT

System

Identifier

Power Source

Weld Cables

Head

Torch

Power Source to

Head

Control Cable

User Interface

ArcLink Digital

Communication

Cable

PLC (w/ User

Interface)

DeviceNet Cables

and Accessories

System Interface

System Interface

to Power Source

Control Cable

Part No.

K2344-1

-or-

K2344-2

K2163-xx

-or-

K1842-xx

K2370-1

-or-

K2312-1

K231-xxx

K1785-xx

K2362-1

K1543-xx 5

Customer

Supplied

Automation

Department or

Customer

Supplied

K2282-1

K1795-xx 5

Single Arc

4

1

1

1

2

1

1

2

1

2,4

1

---

---

---

---

Tandem Arc

4

2

1

2

2

2

2

2

2

2,4

3

---

---

1

2

2

2

Description

Power Wave AC/DC 1000 Power Source

Welding Power Cables

Power Source to contact Nozzle,

and Power Source to Work

K2163 Series cables sold in pairs.

K1842 Series cables sold individually.

See Price Book for details and bulk cable

availability.

Power Feed 10S Head for 3/32 to 7/32 in. solid

wire (includes hopper, wire straightener, cross

seam adjuster, head mounting hardware, and 2 -

5ft 4/0 weld cables).

Power Feed 10S Head for 3/32 to 7/32 in. solid

wire (fixture builder's head, with wire straightener -

insulators not included).

Submerged Arc Contact Nozzle Assembly

Feeder Control Cable (14 pin).

Power Feed 10A Controller

ArcLink Control Cables (5 pin).

Single Arc:

(1) PF-10A Controller to the power source

Tandem Arc:

(1) Lead Arc to System Interface

(2)System Interface to Lead Arc PF-10A

Controller

(3) Trail Arc to Trail Arc PF-10A Controller

Triple Arc:

(1) Lead Arc to System Interface

Programmable Logic Controller

(DeviceNet compatible)

DeviceNet Cables, Tees, and Terminators (5 pin)

sealed "mini style") form a trunk style network con-

necting PLC to each power source and the System

Interface.

For additional information refer to the "DeviceNet

Cable Planning and Installation Manual" (Allen

Bradley publication DN-6.7.2).

Power Wave System Interface provides the

means to synchronize the AC wave shapes of up

to four different arcs to a common carrier frequen-

cy, and control the phase angle between them to

reduce the effects of "Arc Blow".

Control Cable (22 pin) connects between each

power source and the System Interface.

Triple Arc

3,4

3

1

3

2

3

3

2

---

1

1

4

Cables, Tees,

and

Terminators

as required

per Triple Arc

Connection

Diagram

4

1

2

3

2

Refer to "Output Cable Guidelines"

for recommended size and quantity

Notes:

1. "Recommended Quantity" assumes one power source per arc. Multiple power sources may be used to increase the output capacity per arc (see "Connection Diagram - Parallel

Machines").

2. Control Cable connections only required at the Master of each parallel power source arc grouping.

3. Can be expanded to 4 or more arcs (Note: The System Interface can currently only synchronize up to four AC arc groupings).

4. The triple arc system is an economical breakpoint for a PLC Interface. It does not preclude the use of a PLC for single or tandem arc systems, nor PF-10A's from being used to control

multiple arc systems with greater than two arcs.

5. Cables can be connected end to end to extend length.

POWER WAVE® AC/DC 1000