Operation, Caution, B-8 multiple arc system considerations – Lincoln Electric POWER WAVE 11124 User Manual

Page 46: Basic modes of operation, Constant current (cc), Constant voltage (cv)

B-8

OPERATION

B-8

MULTIPLE ARC SYSTEM

CONSIDERATIONS

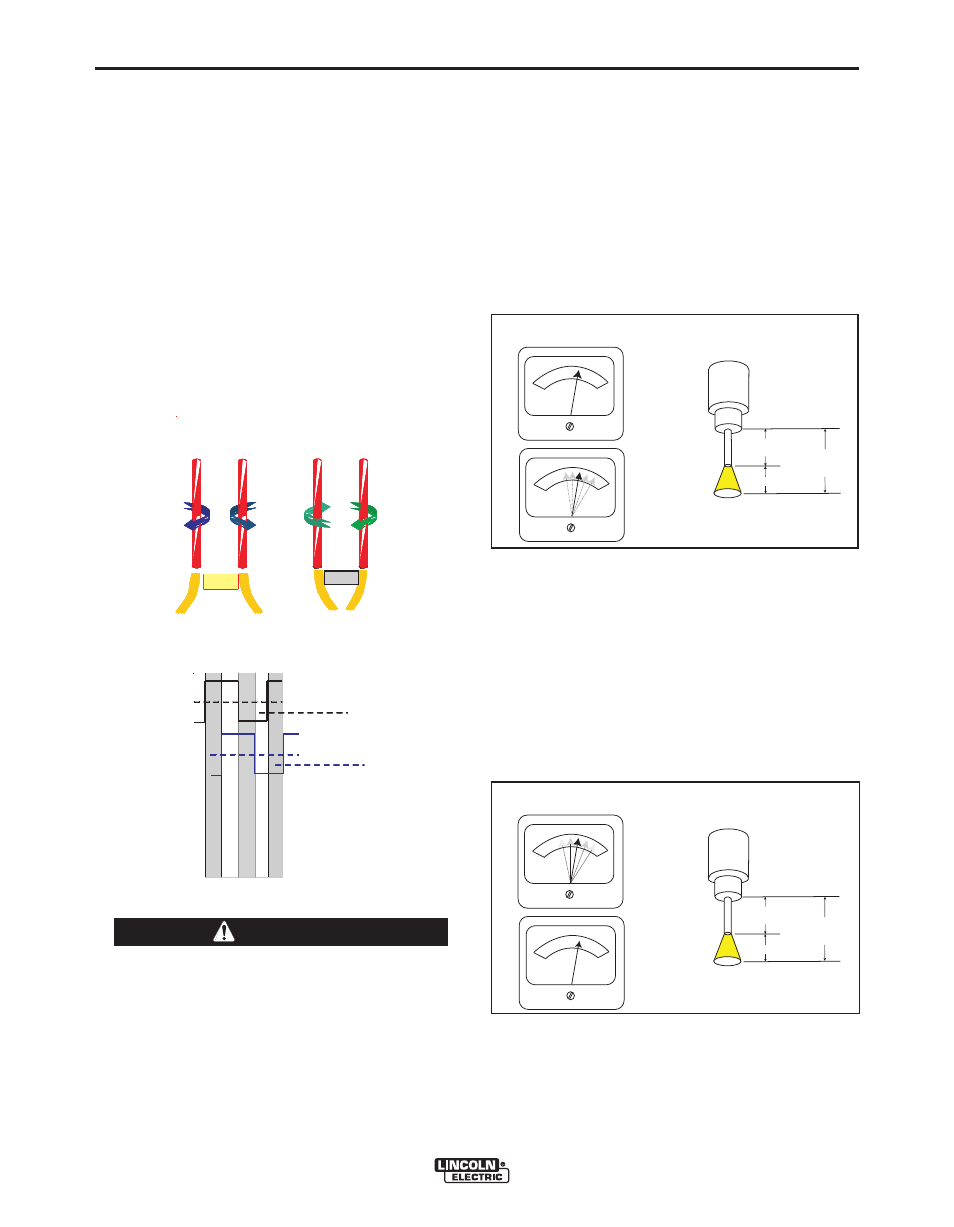

Large scale SAW applications often employ multiple

arcs to increase deposition rates. In multiple arc sys-

tems, magnetic forces created by like and opposing

weld currents of adjacent arcs can result in arc inter-

action that can physically push or pull the arc columns

together. To counteract this effect, the phase relation-

ship between adjacent arcs can be adjusted to alter-

nate and equalize the duration of magnetic push and

pull forces. This is accomplished by the use of an

optional K2282-1 Power Wave System Interface,

which not only synchronizes the arcs, but also

enables adjustment of the phase relationship between

them. Ideally, the net result is a cancellation of the

interacting forces.

FIGURE B.2

FIGURE B.3

Never simultaneously touch electrically "hot"

parts in the electrode circuits of two different

welders. The electrode to electrode no load volt-

age of multiple arc systems with opposite polari-

ties can be double the no load voltage of each arc.

Consult the Safety information located at the front

of the Instruction Manual for additional informa-

tion.

------------------------------------------------------------------------

BASIC MODES OF OPERATION

CONSTANT CURRENT (CC)

• Operator presets Current and desired Voltage.

• The Power Source:

- Goal is to maintain a constant arc length.

- Drives a constant Current.

- Synergically Controls WFS to Maintain Voltage

at the desired Set point.

• Arc Length is proportional to Voltage.

• Traditionally used for larger diameter wires and

slower travel speeds.

CONSTANT VOLTAGE (CV)

• Operator presets Wire Feed Speed and desired

Voltage

• The Power Source:

- Goal is to maintain a constant arc length.

- Commands constant wire feed speed

- Synergically Controls Current to Maintain

Voltage at the desired Set point

• Arc Length is proportional to Voltage

• Traditionally used for smaller diameter wires and

faster travel speeds.

POWER WAVE® AC/DC 1000

+

-

-

+

PUSH

+

+

-

-

PULL

+

-

-

+

+

-

+

PUSH

+

+

-

-

PULL

PUSH

+

+

-

-

+

+

-

+

+

-

-

PULL

Lead Arc

Trai l Arc

P

o

s

it

iv

e

N

e

g

a

ti

v

e

P

o

s

it

iv

e

P

o

s

it

iv

e

N

e

g

a

ti

v

e

N

e

g

a

ti

v

e

P

o

s

it

iv

e

N

e

g

a

ti

v

e

P

o

s

it

iv

e

N

e

g

a

ti

v

e

Lead Arc

Trai l Arc

P

U

S

H

P

U

S

H

P

U

S

H

P

U

L

L

P

U

L

L

CAUTION

Extension

Heating= Vir

Arc Length= Varc

Total Electrical

Stick out

V= Vir+Varc

TO

MAINTAIN CONSTANT

ARC LENGTH

AND

WIRE FEED

SPEED VARIED

CURRENT HELD

CONSTANT

AMPS

CONSTANT CURRENT (CC)

WIRE FEED SPEED

Extension

Heating= Vir

Arc Length= Varc

Total Electrical

Stick out

V= Vir+Varc

TO

MAINTAIN CONSTANT

ARC LENGTH

AND

WIRE FEED SPEED

HELD CONSTANT

CURRENT VARIED

AMPS

CONSTANT VOLTAGE (CV)

WIRE FEED SPEED