Troubleshooting, Caution – Lincoln Electric POWER WAVE 11124 User Manual

Page 61

E-10

TROUBLESHOOTING

E-10

POWER WAVE® AC/DC 1000

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

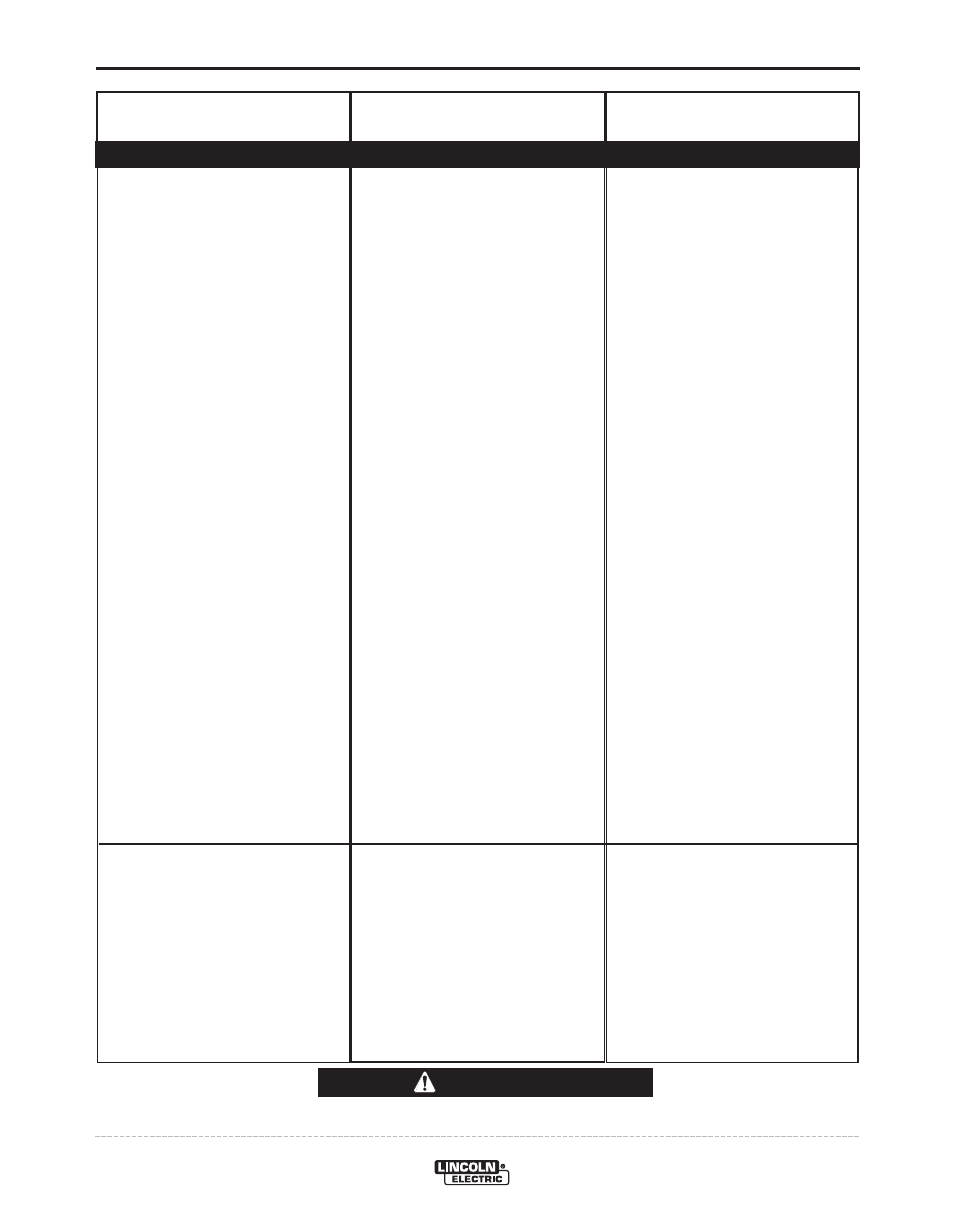

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Bad Weld Ending

Bad Welding

1. Burnback Disabled.

2. Burnback Time.

3. Analog Scans Between Updates.

4. Limit Error reported at the end of a weld.

5. Fan Out.

6. Welding set points.

7. Analog Hysteresis.

8. Gas.

1. Analog Scans Between Updates.

2. Voltage Sense Leads.

1. From the DeviceNet tab of the

Diagnostics Utility, select Monitor. The

Monitor window will be displayed. Verify

under the "State Enabled" that "Burnback"

is present.

2. Using Command Center verify that

Burnback Time for the active schedule in

the main window has a value other than 0.

3. The DeviceNet tab of the Diagnostics

Utility displays the Power Wave’s "Analog

Scans Between Updates" and "I/O

Scans/Sec." Verify that "Analog Scans

Between Updates" is 1/4 of "I/O

Scans/Sec" value.

4. Verify all welding settings for Burnback

and Crater states.

5. From the DeviceNet tab of the

Diagnostics Utility, select Monitor. Verify

under "Analog Input Fan Out" that

Burnback is present for all analogs in.

6. Verify Burnback set points for work point,

trim, and wave values.

7. From the DeviceNet tab of the

Diagnostics Utility, select Configure.

Verify in "Analog Input Channels" that the

Hysteresis settings are all 0.

8. Verify Gas is turned on.

1. The DeviceNet tab of the Diagnostics

Utility displays the Power Wave’s "Analog

Scans Between Updates" and "I/O

Scans/Sec." Verify that "Analog Scans

Between Updates" is 1/4 of "I/O

Scans/Sec" value.

2. Verify voltage sense leads are properly

connected and configured as described in

the instruction manual.

DEVICENET-PLC CONTROLLED SYSTEM