Troubleshooting and repair – Lincoln Electric BULLDOG SVM208-A User Manual

Page 74

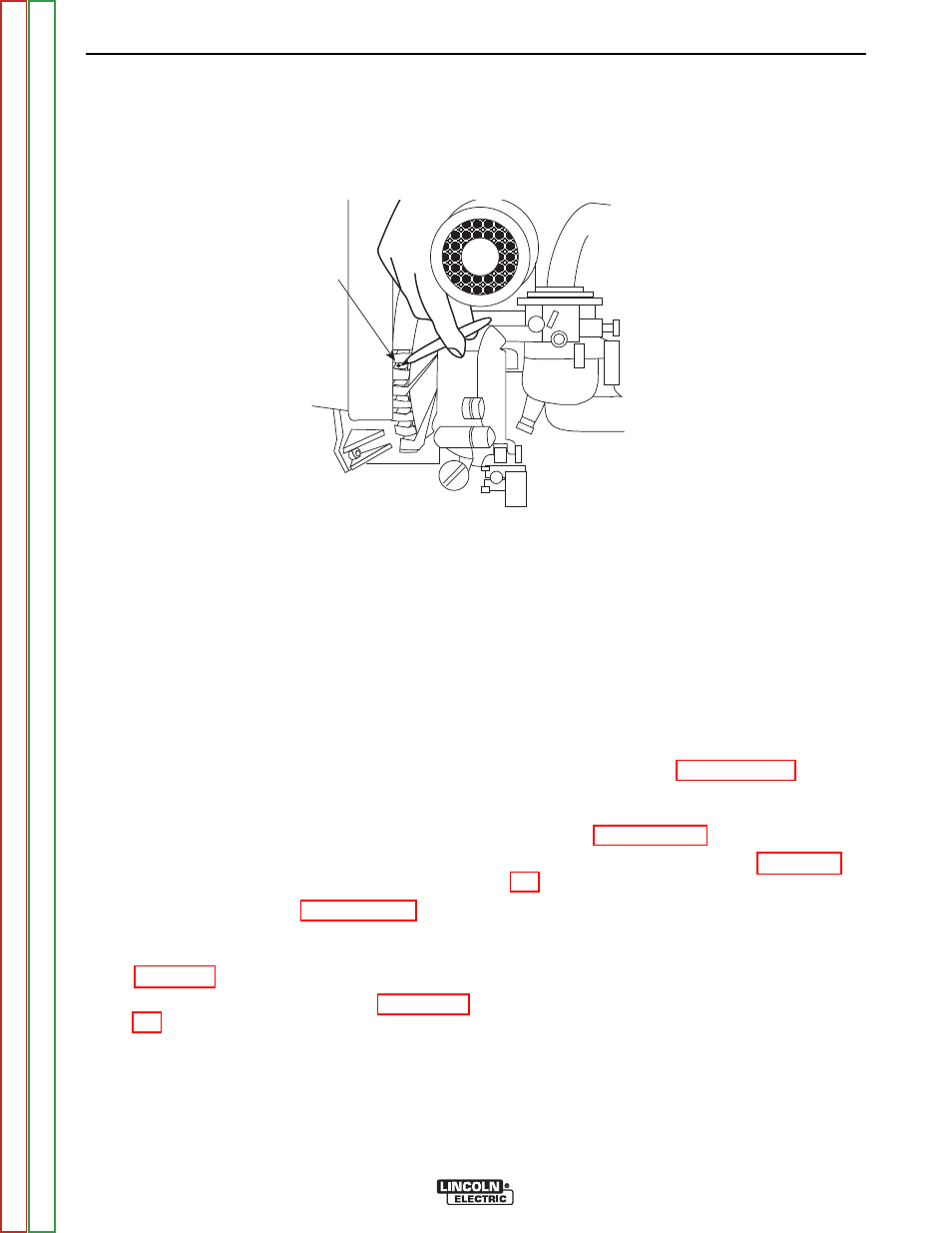

MARK

FIGURE F.7 – MARK LOCATION

ENGINE THROTTLE ADJUSTMENT TEST

ROBIN/SUBARU ENGINE (continued)

PROCEDURE

This test can be conducted by any of three meth-

ods.

Strobe-tach Method:

1. Stop the engine and remove the spark plug wire

to prevent accidental kickback or starting.

2. With the black or red marking pencil, place a

mark on one of the blower paddles, which can

be reached through the vent slots in the end

bracket. See Figure F.7.

3. Connect the strobe-tach according the manu-

facturer’s instructions.

4. Reconnect the spark plug wire and start the

engine. Direct the strobe-tach light on the blow-

er paddle and synchronize it to the rotating

mark. The tach should read 3700 RPM.

5. Using the 10mm socket wrench, slightly loosen

the throttle locking nut. See Figure F.8.

5. Using the screwdriver adjust the high speed

stop screw until the tach reads 3700 RPM. See

Figure F.9.

5. Re-tighten the throttle locking nut. See Figure

Frequency Counter Method:

1. Plug the frequency counter into one of the 115

VAC auxiliary receptacles.

2. Start

the

engine

and

check

the

frequency counter. At the proper RPM (3700),

the counter should read 62 Hz.

3. Using the 10mm socket wrench, slightly loosen

the throttle locking nut. See Figure F.8.

4. Using the screwdriver, adjust the high speed

stop screw until the frequency counter reads

3700 RPM. See Figure F.9.

5. Re-tighten the throttle locking nut. See Figure

Oscilloscope Method:

1. Connect the oscilloscope according to the man-

ufacturer’s instructions. At 3700 RPM, the

waveform should exhibit a period of 16.2 mil-

liseconds. Refer to the NORMAL OPEN

CIRCUIT VOLTAGE WAVEFORM (115 VAC

SUPPLY) HIGH IDLE - NO LOAD in this section

of the manual.

TROUBLESHOOTING AND REPAIR

F-26

F-26

BULLDOG® 140