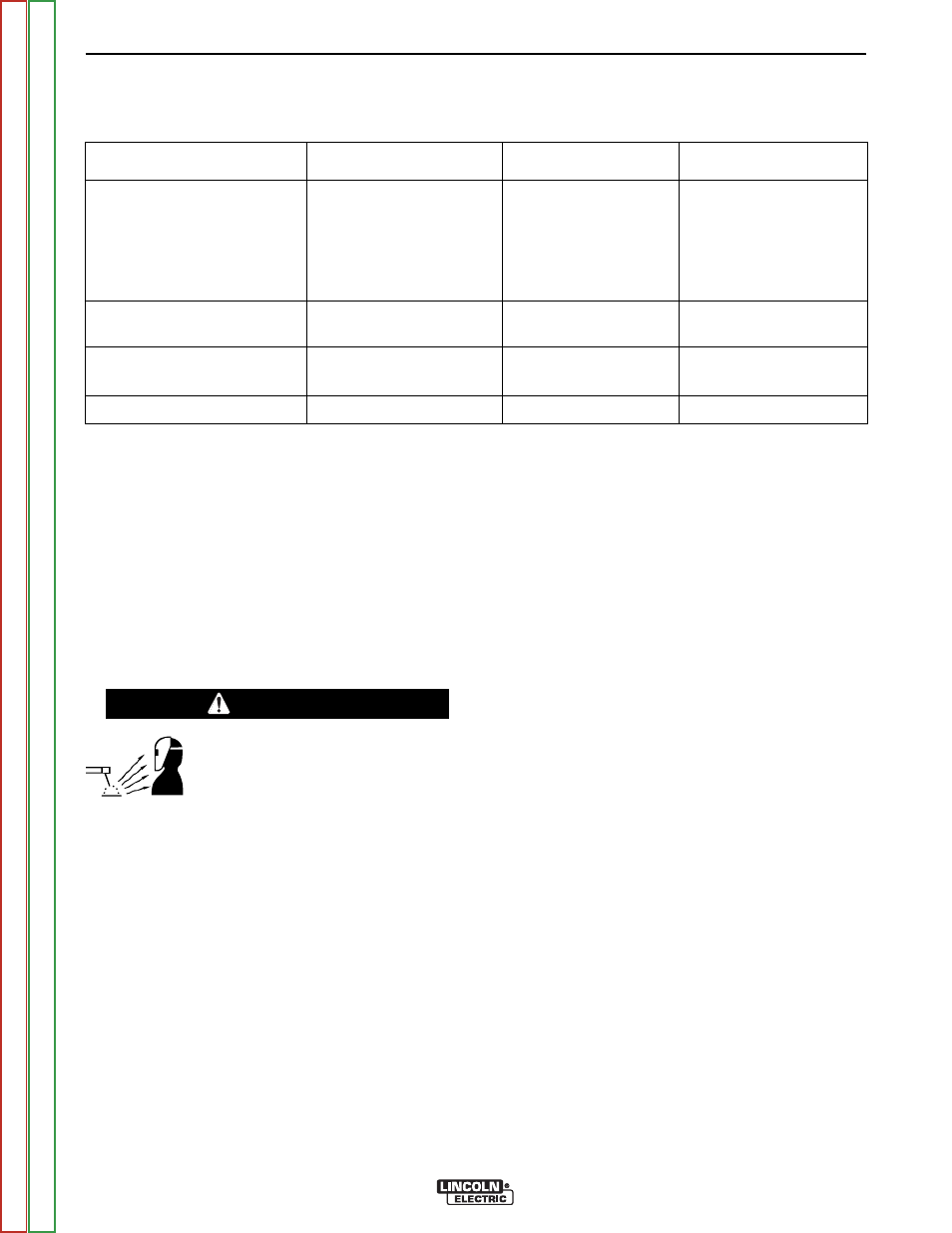

Table b.2 , welding applications, See table b.2 ), Welding guide- lines – Lincoln Electric BULLDOG SVM208-A User Manual

Page 25: To table b.2, Operation, Stick welding, Welding guidelines, Learning to stick weld, Warning

OPERATION

B-9

B-9

BULLDOG® 140

Stick welding is probably the most familiar welding

process known. A coated ELECTRODE, the weld rod,

is clamped into an ELECTRODE HOLDER, an insulat-

ed clamping device, which in turn connects to the

ELECTRODE CABLE, a heavy wire. The WORK, the

metal piece to be welded, is connected to the WORK

CABLE, a heavy wire which contains the WORK

CLAMP. Quality Lincoln cables use many fine copper

wires with a very flexible insulating covering for the

electrode and work cables. When properly connected

to the OUTPUT STUDS of a high current power

source, the electrode melts and bonds the metal being

repaired. See “Cable Installation” section for proper

cable connection to a Power-Arc.

The Power-Arc provides excellent weld output charac-

teristics when used in combination with Lincoln AC

electrodes. Other AC electrodes may also be used.

Follow the settings listed in Table B.2 “Welding

Application Guide” and the “Electrode Selection Guide”

found on the nameplate of the machine.

ARC RAYS can burn.

• When using an open arc process, it

is necessary to use correct eye,

head and body protection.

------------------------------------------------------------------------

Stick Welding

Semi-automatic, Wire Welding With a

Lincoln Wire Feeder / Welder

The Bulldog® 140 generator power can be used to

supply power up to 4,000 watts continuous input power

to a Lincoln Wire Feeder/Welder. The Wire

Feeder/Welder is equipped with all the supplies need-

ed for Flux-Cored Arc Welding (FCAW). Also some

Wire Feeder/Welders come equipped with the essen-

tials needed for Gas Metal Arc Welding, GMAW, or

MIG processes, while others require the purchase of a

conversion kit. These products are available where

Lincoln products are sold. Contact your local autho-

rized Lincoln representative for more details.

Material Thickness

Electrode Type

Size

Setting

FLEETWELD

®

37

90 amps

1

AWS E6013

1/8” and thinner

FLEETWELD

®

180

3/32”

70 amps

AWS E6011

Lincoln 7018 AC

90 amps

AWS E7018

3/16” Maximum

FLEETWELD

®

37

1/8”

125 amps

AWS E6013

5/16” Maximum

FLEETWELD

®

180

1/8”

90 amps

AWS E6011

Any Thickness

WEARSHIELD

®

ABR

1/8”

100 amps

WELDING GUIDELINES

TABLE B.2

WELDING APPLICATIONS/ELECTRODE SELECTION GUIDE

NOTES:

The values listed are suggested settings. Actual setting

may vary depending on individual preference and/or

specific application. Beginners should use Lincoln

E7018 AC.

For electrodes not listed, follow tables that are packed

with the electrodes.

Ask for the Lincoln WELD DIRECTORY (Publication

C2.10) for a complete listing of all Lincoln stick elec-

trodes available.

1

AWS = American Welding Society

Learning To Stick Weld

The serviceability of a product or structure utiliz-

ing this type of information is and must be the sole

responsibility of the builder/user. Many variables

beyond the control of The Lincoln Electric

Company affect the results obtained in applying

this type of information. These variables include,

but are not limited to, welding procedure, plate

chemistry and temperature, weldment design, fab-

rication methods and service requirements.

WARNING