Asme addendum, Water connections – Lochinvar EnergyRite ER302 User Manual

Page 49

11

ASME addendum

(continued)

Installation & Operation Manual

49

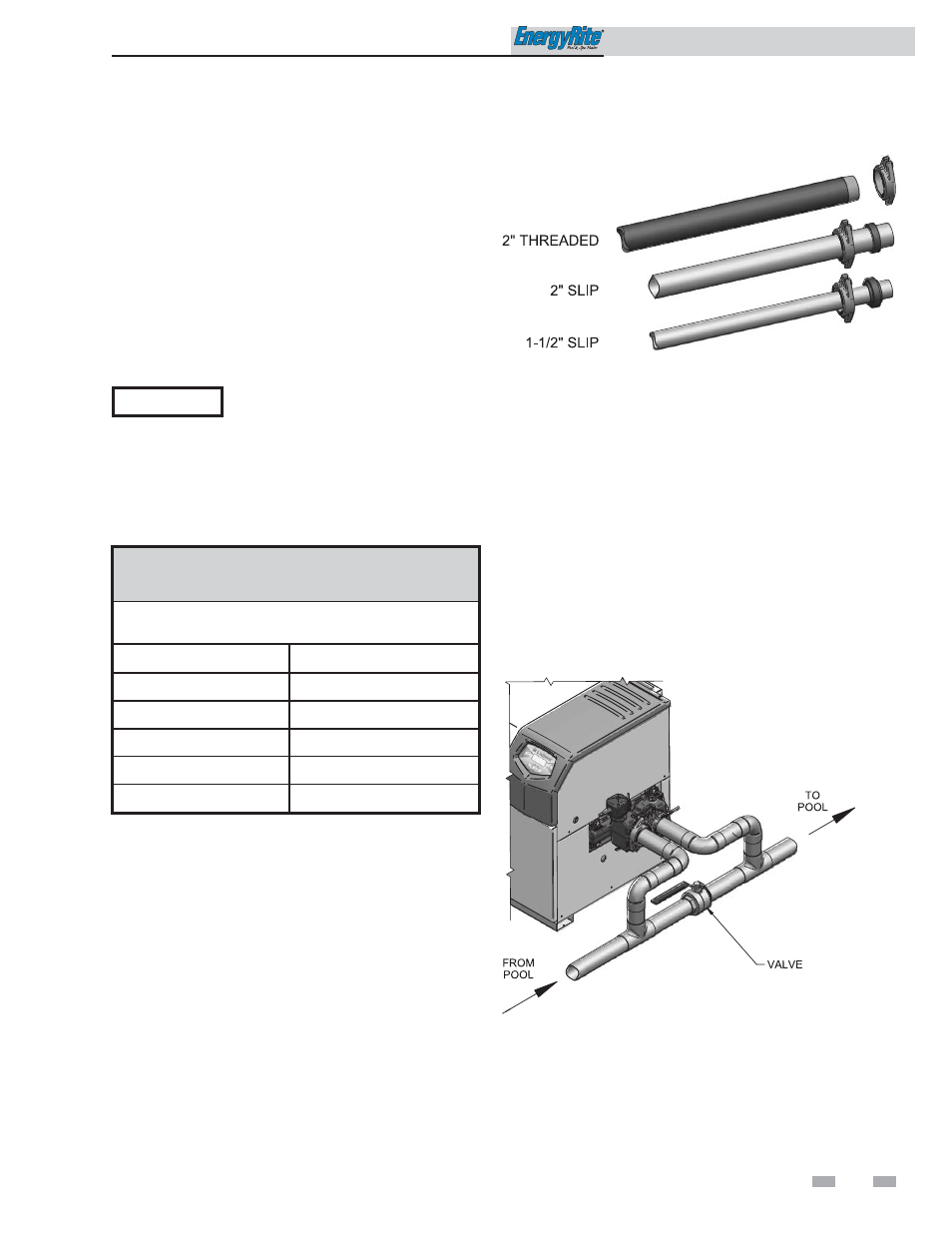

Water connections

Inlet and outlet connections

Connection to the pool heater can be made with either 2"

threaded pipe or a slip connection with 1 1/2" or 2" pipe.

Two inch threaded pipe may be directly screwed into the

flanged header connections for both inlet and outlet piping.

Each pool heater is supplied with two sets of gaskets to allow

a flanged compression attachment of either 2" or 1 1/2"

copper pipe directly to the front header. Ensure that the

correct gasket is used to match the pipe diameter used.

Minimum pipe size for installation of the pool heater is

1 1/2" diameter.

NOTICE

The pool heater installation may require

a 3/4" drain pipe. Check with your local

code authorities. In these applications,

install a 3/4" threaded connection in the

piping, located immediately downstream

of the inlet/outlet connection on the

front header for system drainage.

A metallic pipe heat sink is not required on pool heater

installations. PVC, CPVC, or other high temperature plastic

piping may be used to pipe directly to the pool heater if

permitted by local codes. When the pool heater is used with

a spa or therapy pool, CPVC or metallic pipe is

recommended. A silicon type sealant with a high elasticity

must be used at flanged connections to prevent leakage.

This helps to compensate for the large differences in

expansion and contraction of the materials used in piping

and the flanged connections. The filtration pump must

operate simultaneously when the heater is in service to

ensure that there is no damage to PVC piping connected

directly to the pool heater. A check valve should be installed

in the piping to the heater if there is the possibility of “back

siphoning” when the pump stops.

Figure 11-1_ Alternate Piping Connections

Auxiliary bypass

When water flow rates to the pool heater exceed 100 GPM, a

portion of this high water flow must be diverted with an external

bypass. High performance pumps can provide flows in excess of

100 GPM. An auxiliary bypass as shown in FIG. 11-2 must be

installed when the maximum flow is exceeded. The bypass must

have a valve installed between the connections to the pool heater

to allow a portion of the excess flow to be diverted to the pool.

The bypass allows the proper volume of water to be supplied to

the pool heater to prevent sweating and condensate. The

bypassed water prevents needless pressure drop and reduction in

flow rates.

Figure 11-2_ Auxiliary Bypass Piping

TABLE - 11A

MINIMUM WATER FLOW REQUIREMENTS

Minimum water flow rates to ensure proper operation

are as follows:

Model

Minimum Flow

ER152-A

15 GPM

ER202-A

20 GPM

ER252-A

25 GPM

ER302-A

30 GPM

ER402-A

40 GPM