Gas connections – Lochinvar EnergyRite ER302 User Manual

Page 32

Installation & Operation Manual

32

6

Gas connections

Gas supply

Verify unit is supplied with the type of gas specified on the

rating plate. This unit is orificed for operation up to 4000 feet

altitude. Consult factory for installations above 4000 feet

elevation.

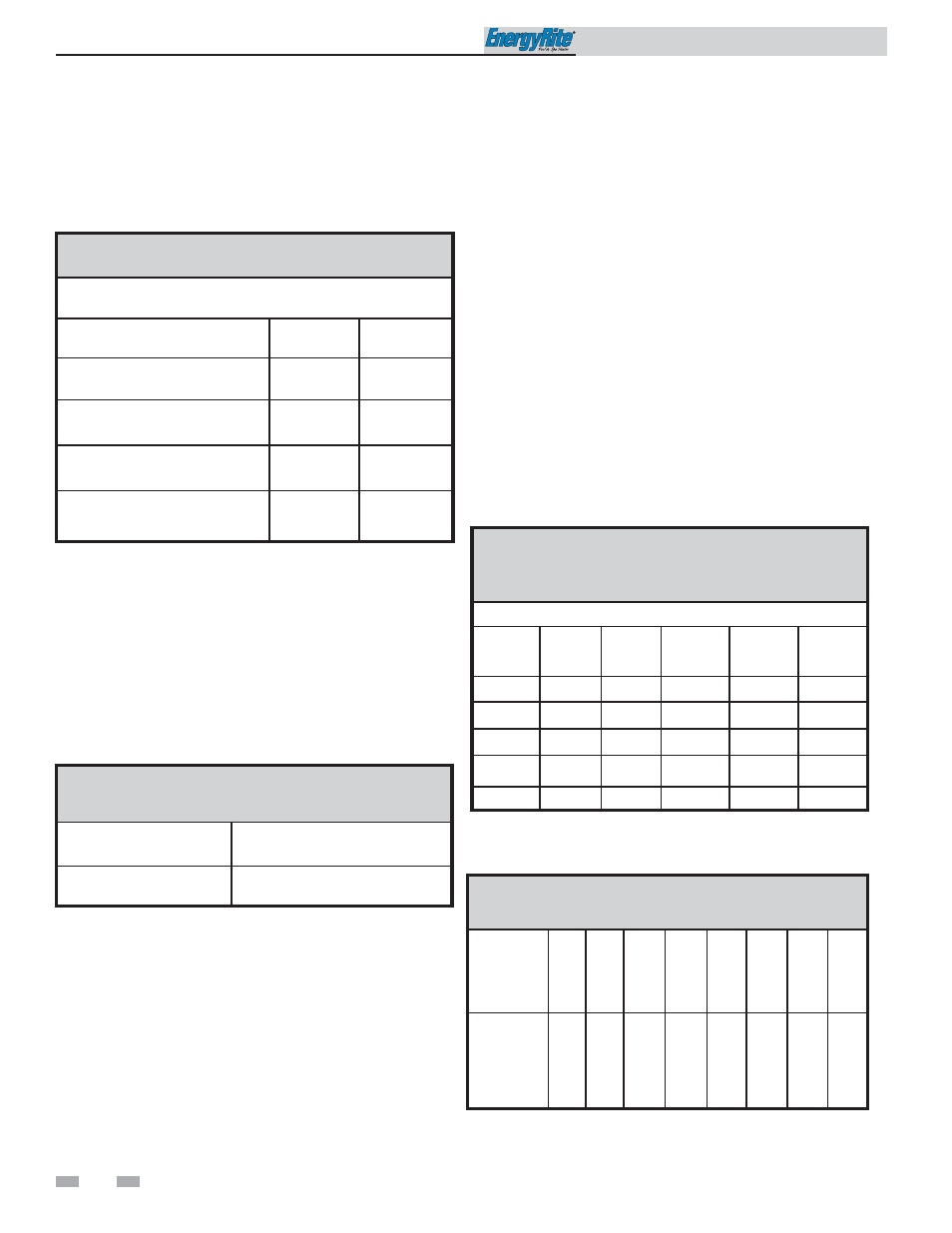

TABLE - 6A

INLET GAS PRESSURE

Measured at the inlet pressure tap located upstream of the

combination gas valve.

Model

Number

Natural

Gas

LPG

ER152 - ER202

Min. (Inches Water Column)

4.0

8.0

ER252 - ER302

Min. (Inches Water Column)

4.5

8.0

ER402

Min. (Inches Water Column)

5.0

8.0

ER152 - ER402

Max. (Inches Water Column)

14.0

14.0

Maximum inlet gas pressure must not exceed the value specified.

Minimum value listed is for the purposes of input adjustment.

MANIFOLD PRESSURE: Measured as a net pressure between

the pressure tap on the downstream side of the gas valve and the

chamber pressure. Connect one side of the manometer to the

chamber pressure, and the other to the outlet pressure tap. If

adjustment of the regulator pressure is required, see the

Manifold Adjustment Procedure section in the EnergyRite Service

Manual. Do not increase regulator pressure beyond specified

pressure settings.

TABLE - 6B

NET MANIFOLD PRESSURE

Model

Number

Natural and LP Gas

Regulator Setting

ER152 - ER402

(Inches Water Column)

1.8 (Nat.) 4.6 (LP)

Gas pressure test

1.

The pool heater must be disconnected from the gas

supply piping system during any pressure testing of that

system at a test pressure in excess of 1/2 PSIG (3.5 kPa).

2.

The pool heater must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 PSIG (3.5 kPa).

3.

The pool heater and its gas connection must be leak-

tested before placing the heater in operation.

Gas connection

Safe operation of the unit requires properly sized gas supply

piping. See the following data:

1.

Gas pipe size may be larger than heater connection.

2.

Installation of a union is highly recommended for ease of

service. Install union as close as possible to gas valve inlet.

3.

Install a manual main gas shutoff valve, outside of the

appliance gas connection and before the gas valve, when

local codes require.

4.

A trap (drip leg) must be provided in the inlet of the gas

connection to the unit.

5.

The combination gas valve has an integral vent limiting

device and does not require venting to atmosphere,

outside the building.

6.

Optional gas controls may require routing of bleeds and

vents to the atmosphere, outside the building when

required by local codes.

TABLE - 6C

LOW PRESSURE SINGLE UNIT INSTALLATIONS

SUGGESTED GAS PIPE SIZE

DISTANCE FROM METER

Model

Number

0 - 50' 51' - 100' 101' - 200' 201' - 300' 301' - 500'

ER152

3/4"

1"

1 1/4"

1 1/4"

1 1/2"

ER202

1"

1"

1 1/4"

1 1/2"

2"

ER252

1"

1 1/4"

1 1/2"

1 1/2"

2"

ER302

1 1/4"

1 1/4"

1 1/2"

1 1/2"

2"

ER402

1 1/4"

1 1/4"

1 1/2"

2"

2"

For each elbow or tee, add equivalent straight pipe to total

length from Table 6D.

TABLE - 6D

FITTINGS TO EQUIVALENT STRAIGHT PIPE

Diameter

Pipe

3/4"

1"

1 1/4" 1 1/2"

2"

3"

4"

5"

Equivalent

length of

Straight

Pipe

2'

2'

3'

4'

5'

10'

14'

20'