Conventional venting, A conventional negative draft venting system – Lochinvar EnergyRite ER302 User Manual

Page 17

Installation & Operation Manual

3

Conventional venting

17

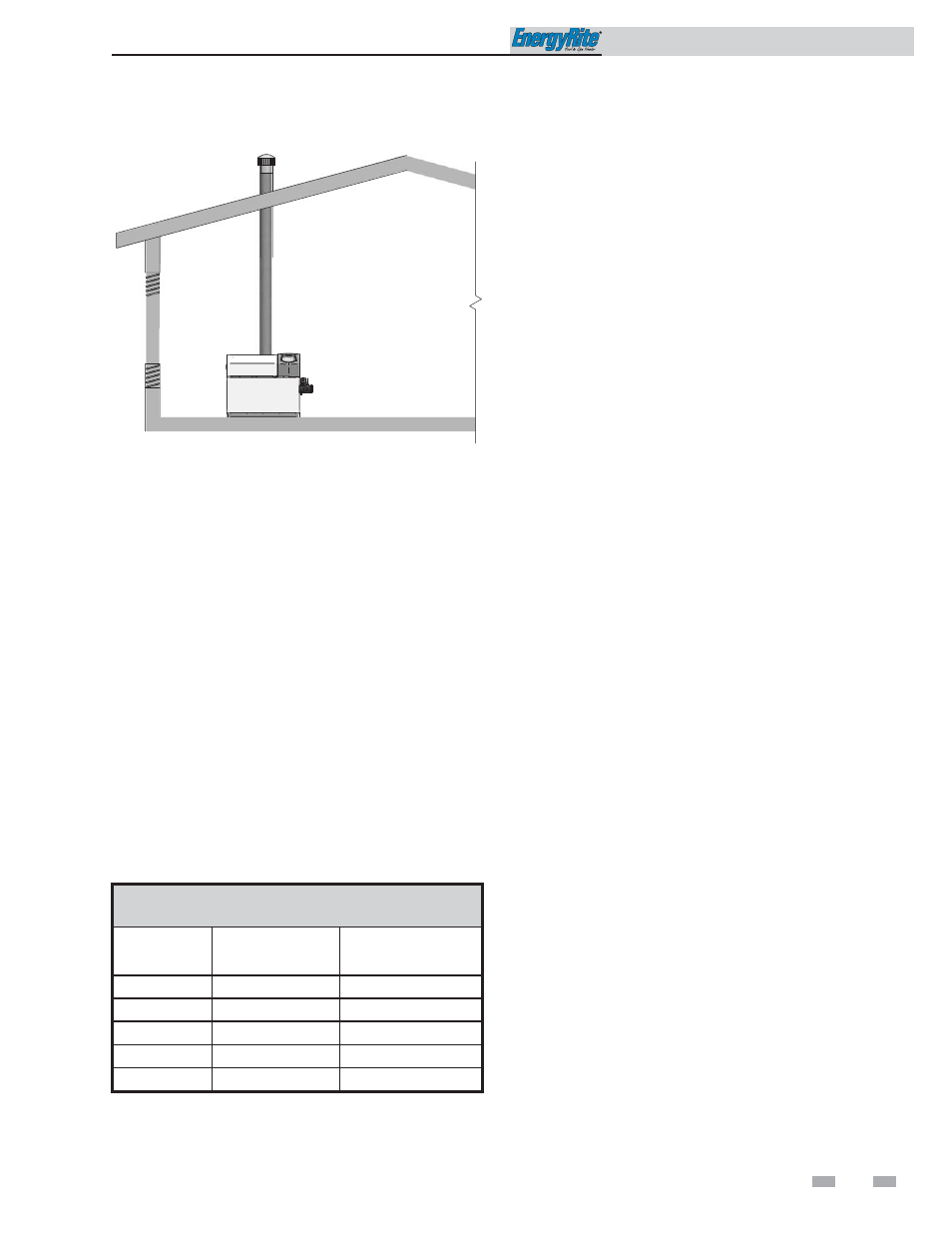

Figure 3-1_Conventional Negative Draft Vertical

Venting with Combustion Air Louvers

A conventional negative draft venting system

The outdoor vent cap assembly must be removed before any

connection to a conventional negative draft vent system can

be made. A conventional vent adapter kit must be installed

on the pool heater’s flue outlet. The conventional vent kit

includes the flue adapter and an air inlet cover. Mount the

air inlet cover over the combustion air inlet opening on the

rear of the jacket. No additional draft diverter or

barometric damper is required on single unit installations

with a dedicated stack and a negative draft within the

specified range of a negative 0.02 to 0.08 inches water. If the

draft in a dedicated stack for a single unit installation

exceeds the maximum specified draft, a barometric damper

must be installed to control draft. Multiple unit

installations with combined venting or common venting of

this pool heater with other Category I negative draft

appliances requires that each pool heater must have a

barometric damper installed to regulate draft within the

proper range.

TABLE - 3A

CONVENTIONAL VENT DATA

Model

Number

Conventional Vent

Flue Size

Conventional Vent

Kit Number

ER152

5"

CVK3004

ER202

5"

CVK3004

ER252

6"

CVK3005

ER302

6"

CVK3006

ER402

6"*

CVK3006

The negative draft in a conventional vent installation must

be within the range of a negative 0.02 to 0.08 inches water

to ensure proper operation. All draft readings are made

while the unit is in stable operation (approximately 2 to 5

minutes). Remember that the draft in a conventional

negative draft vent may vary seasonally. A pool heater

with a high draft when operating in the winter months

may have a much lower draft in the summer. Initial set-up

of a vent system with a draft of not more than a negative

0.05 inches water will generally ensure that increased draft

in the winter months will not exceed the specified

maximum. Maximum draft can not exceed a negative

0.08 inches of water.

On a conventionally vented, negative draft pool heater, the

connection from the vent to the stack or vent termination

outside the building must be made with listed Type “B”

double-wall (or equivalent) vent connectors and must be

direct as possible with no reduction in diameter. Use the

National Fuel Gas Code venting tables for double-wall

vent to properly size all vent connectors and stacks. The

Type “B” vent and accessories, such as firestop spacers,

thimbles, caps, etc., must be installed in accordance with

the manufacturer’s instructions. The vent connector and

firestop must provide correct spacing to combustible

surfaces and seal to the vent connector on the upper and

lower sides of each floor or ceiling through which the vent

connector passes.

Any vent materials specified must be listed by a nationally

recognized test agency for use as vent material.

Locate the pool heater as close as practicable to chimney

or gas vent.

Avoid long horizontal runs of the vent pipe, 90° elbows,

reductions and restrictions. Horizontal portions of the

venting system shall be supported to prevent sagging.

Horizontal runs must slope upwards not less than 1/4 inch

per foot from the appliance to the vent terminal.

Do not use an existing chimney as a raceway for a flue pipe

if another appliance or fireplace is vented through the

chimney.

The weight of the venting system must not rest on the

unit. Adequate support of the venting system must be

provided in compliance with local codes and other

applicable codes. All connections should be secured with

rustproof sheet metal screws.

Vent connectors serving appliances vented by natural draft

MUST NOT be connected to any portion of a mechanical

draft system operating under positive pressure.

Connection to a positive pressure stack may cause flue

products to be discharged into the living space causing

serious health injury.

*On the ER402 model you MUST have at least 8 feet of

vertical vent to use a 6" vent , if less than 8 feet the vent size

must increase to 7".