Water connections – Lochinvar EnergyRite ER302 User Manual

Page 34

34

Installation & Operation Manual

7

Water connections

This pool heater is equipped with an automatic, built-in bypass

located in the front header. This bypass is flow actuated to

maintain proper flow through the pool heater at flow rates of

less than 100 GPM. If the water flow rate to the pool heater

exceeds 100 GPM, an auxiliary bypass must be installed in the

piping to the pool heater. See the Auxiliary Bypass section for

piping and adjustment.

If the flow rate is unknown, ensuring the temperature rise across

the pool heater is between 10°F and 15°F will ensure the proper

flow rate (reference the Service Menu Descriptions - Delta T

section of the EnergyRite Service Manual).

TABLE - 7A

MINIMUM WATER FLOW REQUIREMENTS

Minimum water flow rates to ensure proper operation are

as follows:

Model

Minimum Flow

ER152

15 GPM

ER202

20 GPM

ER252

25 GPM

ER302

30 GPM

ER402

40 GPM

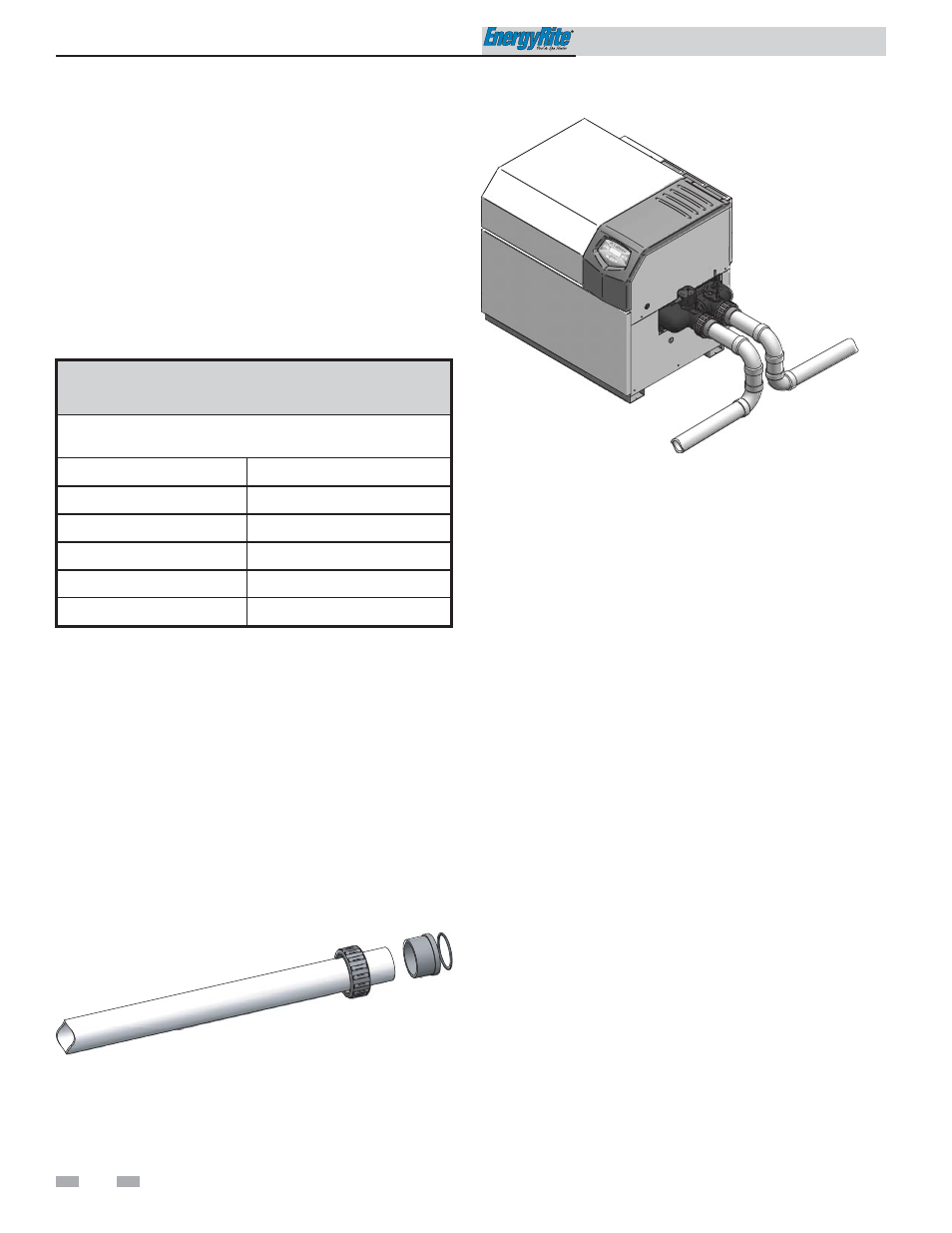

Figure 7-2_Typical Piping for Water Connections

Inlet and outlet connections

Connections can be made with 2" slip connections to both the

inlet and outlet connections. Included with the unit are two

CPVC union nuts (WTR2102), two CPVC tail pieces

(MSC2213), and two gaskets (GKT2071). Assemble the gasket

and tail piece with the union nut as shown in FIG. 7-1. Make

slip connections to the tail pieces using proper cement and

primer.

To use something other than PVC or CPVC pipe, connect the

tail pieces and gaskets with the union nuts as described above.

Connect six inches of PVC or CPVC pipe to the tail pieces as

described above. Connect a slip NPT adapter to the other end

of the six inch pipe. All other piping can be made there.

For ASME models please see the ASME Addendum section of

this manual for water connections.

A metallic pipe heat sink is not required on pool heater

installations. When the pool heater is used with a spa or therapy

pool, CPVC or metallic pipe is recommended. The filtration

pump must operate simultaneously when the heater is in service

to ensure that there is no damage to the piping connected

directly to the pool heater. A check valve should be installed in

the piping to the heater if there is the possibility of “back

siphoning” when the pump stops.

Auxiliary bypass

When water flow rates to the pool heater exceed 100 GPM, a

portion of this high water flow must be diverted with an

external bypass. High performance pumps can provide flows in

excess of 100 GPM. An auxiliary bypass as shown in FIG. 7-3

must be installed when the maximum flow is exceeded. The

bypass must have a valve installed between the connections to

the pool heater to allow a portion of the excess flow to be

diverted to the pool. The bypass allows the proper volume of

water to be supplied to the pool heater to prevent sweating and

condensate. The bypassed water prevents needless pressure

drop and reduction in flow rates.

Figure 7-1_Piping Connection Assembly