Gas connections – Lochinvar EnergyRite ER302 User Manual

Page 33

6

Gas connections

(continued)

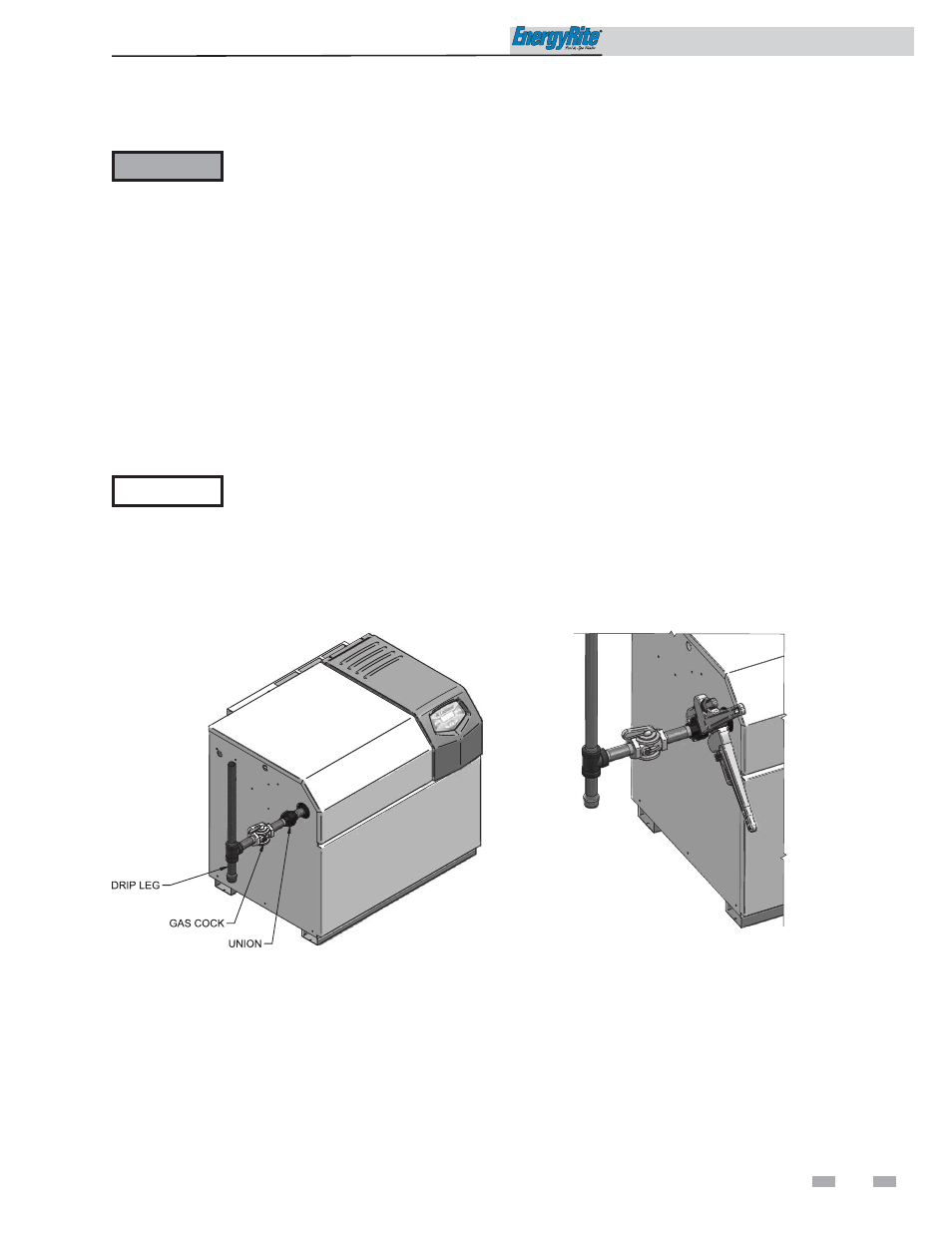

Figure 6-1_Gas Line Connection to unit w/sediment

trap and manual main gas shut-off valve

Gas piping

All gas connections must be made with pipe joint

compound resistant to the action of liquefied petroleum

and natural gases. All piping must comply with local codes

and ordinances. Tubing installations must comply with

approved standards and practices.

Figure 6-2_Wrench to Support Gas Valve for Piping

Connection

8.

Connect the gas pipe to the inlet of the unit. Use a wrench

to support the gas manifold on the unit (FIG. 6-2).

9.

For LP gas, consult your LP gas supplier for expert

installation.

10. Ensure that all air is properly bled from the gas line before

starting the ignition sequence. Start up without properly

bleeding air from the gas line may require multiple reset

functions of the ignition control module to achieve

proper ignition.

Install piping to gas valve

1.

The gas line should be a separate line direct from the

meter unless the existing gas line is of sufficient capacity.

Verify pipe size with your gas supplier.

2.

Use new, properly threaded black iron pipe free from

chips. If tubing is used, make sure the ends are square,

deburred, and clean. All tubing bends must be smooth

and without deformation. Avoid flexible gas connections.

Internal diameter of flexible lines may not provide the unit

with the proper volume of gas.

3.

Install a manual main gas shutoff valve at the pool

heater’s gas inlet, outside of the pool heater and before

the gas valve. When the pool heater is installed in, under,

or directly attached to the pool or spa structure, the

manual main gas shutoff valve must be located outside

the pool structure.

4.

Run pipe or tubing to the pool heater’s gas inlet. If

tubing is used, obtain a tube to pipe coupling in order to

connect the tubing to the pool heater’s gas inlet.

5.

Install a sediment trap (drip leg) in the supply line to the

pool heater’s gas inlet (see FIG. 6-1).

6.

Apply a moderate amount of good quality pipe

compound (DO NOT use Teflon tape) to pipe only,

leaving two end threads bare.

7.

Remove seal over gas inlet to pool heater.

LP gas installations

LP (propane) gas is heavier than air and

will remain at floor level if there is a leak.

Basements, crawl spaces, alcoves, and

areas below ground level will serve as

pockets for accumulation of leaking gas.

Before lighting, sniff at floor level. If you

smell gas, follow instructions on page 3

of this manual. Shut off gas at LP tank

outside of the building. DO NOT

operate appliance until leakage is

corrected.

ƽ WARNING

LP gas cylinders shall be located outdoors and away from

the pool structure in accordance with the latest edition of

the Standard for the Storage and Handling of Liquefied

Petroleum Gases, ANSI/NFPA 58, or CAN/CSA B149.2, and

applicable local codes.

Installation & Operation Manual

33

NOTICE

If an inline high gas pressure regulator is

used, it must be located a minimum of

10 feet from the appliance. Failure to do

so may result in insufficient gas volume

supplied to the appliance.