Sen so r s, Warning – Lochinvar 399 User Manual

Page 68

Hydronic Heating Boilers and

Domestic Water Heaters

68

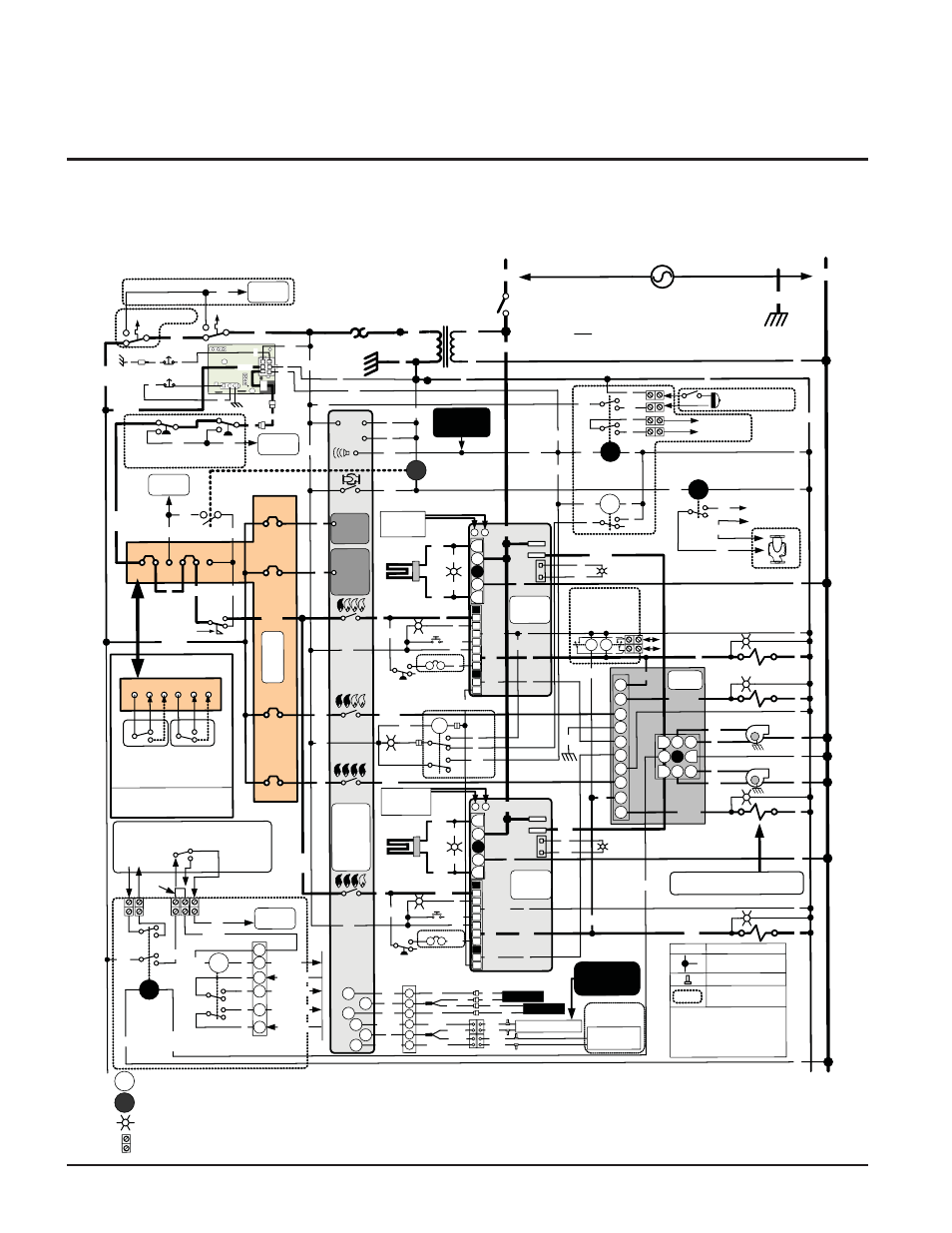

LADDER DIAGRAM 990,000 - 2,070,000 BTU/HR MODELS

24 VAC

CONTROL

J3

5

4

6

1

2

3

O.C.

J1

J2

3

2

1

J4

P

O

NC

BR/

W

ALARM INPUTS

1, 2, 3 & 4

JOIN HERE

S2/FS

F2

F1

LINE

S1

O/W

PRESSURE

SWITCH #2

RESET

PURGE

Y

P

T/W

S2/

FS

-

+

F2

F1

NEU

LINE

S1

O

G

R

PRESSURE

SWITCH #1

RESET

PURGE

GY

GY

PUMP RELAY

BK

BK

STAGE #2

BLOWER #1

W

W

W

Y

~~~~

~~~~

STAGE #1

16

15

18

17

22

21

20

19

HEAT

DEM

#1

EL

EC

TR

O

NI

C

TEMP

ERAT

U

RE

C

ON

TRO

LL

ER

OPTIONAL

RUN TIME

RELAY

CONTACTS

LBL20012 REV A

24 VAC

12

24

23

120 VAC

1

14

13

+

-

HD-

Y

Y

W

CHASSIS

GROUND

-

INTERMITTENT

ALARM ENABLE

RELAY

Y

Y

2NO

2C

4NO

4C

1NO

1C

3NO

3C

BK

BK

R

R

BK/W

G

W

Y

OPTIONAL

CONTACTS

ANY FAILURE

IGNITER

TRIAL

GY

GY

BK

P

BL

O

O

O/W

O/

W

R/O

BL

BR

BR

BK

G

NEU W

W

CIRCUIT BREAKER

BL

+

ALARM

CONTACTS

OPTIONAL ALARM

BELL 24V OUTPUT

SILENCE

BL

ALARM

G

BL

Y

C1

C2

NO1

NO2

PROVING RELAY

C1 NO1

A1

B1

A2 A3

B2 B3

CONTINUOUS INTERMITTENT

FLOW

SWITCH

O

STATUS

Y

CHASSIS

GROUND

CHASSIS

GROUND

SEN

SO

R

S

IGNITER

TRIAL

GY/

W

HI-LIMIT

AUX. HI-LIMIT

PR

ALARM

INPUT 4

BK

1

2

BK

L

A

R

T

U

E

N

E

N

I

L

GROUND

BL

ALARM

INPUT 3

O/

BK

BR

BL

PR/

BK

BL

PR/BK

STAGE #1

STAGE #4

STAGE #3

BLOWER #2

Y

Y

Y

Y

W

W

W

Y

R

R/O

R/O

R/BK

R/W

BL

R

120 VAC 15AMPS

60Hz

O/BK

R/

BK

R/

W

BL

Y

PR

PR

Y

PR

BK/

W

BR/W

BR/W

BR

BR

W

PR

PR

T

PR/BK

PR/BK

BR/W

BR/W

BR/W

PR /BK

PR /BK

BR/W

Y

Y

PROVING

SWITCH

MOTOR

CONTACTS

W

BK/W

BK/

W

W

BR

T

T

B

R

B

R

ON/OFF

POWER

SWITCH

PR

R/

O

LOUVER /

VENTER

ENABLE/

CONTACT

RELAY

FIELD SUPPLIED LOUVER /

POWER VENTER CONNECTIONS

TEST

SWITCH

T

RESET

PR

T

(1) WHERE POSSIBLE, ALL SWITCHES AND CIRCUITRY ARE SHOWN IN THEIR AT REST STATES

.

NOTES:

(2) ADDITION OF ENERGY MANAGEMENT SYSTEMS OR OPTIONAL LIMIT SWITCHES TO THE TERMINAL

(3) SCHEMATIC IS WIRING DIAGRAM, REFER TO ACTUAL COMPONENTS FOR EXACT TERMINAL LOCATIONS.

DOTTED LINE

INDICATES OPTIONAL

EQUIPMENT

ITEM

INDICATES

CLOSED END SPLICE

JUNCTION POINT

(ELECTRICALLY SAME)

T=TAN

Y=YELLOW

BR=BROWN

G=GREEN

GY=GRAY

W = WHITE

BK = BLACK

PR=PURPLE

BL=BLUE

P=PINK

O=ORANGE

(4) WHEN REPLACING DAMAGED WIRING, USE EQUIVALENT TYPE AND GAUGE.

TD

P

P

PROBE

BL/

BK

Y

PUMP

STAGE #2

STAGE #4

STAGE #3

AE

PU

LE

PR

HIGH

LOW

BL/W

OPTIONAL LOUVER/VENTER

CONTROL RELAYS

R

R

= RELAYS LO CATED O N CO NTRO L

PANEL

= RELAYS LO CATED IN W IRING BO X

OPEN

CLOSED

COM

PROVING RELAY

C2 NO2

R/O

Y/G = YELLOW WITH GREEN STRIPE

R=RED

RELAY

BOARD

HD#1

HD#2

ALARM

INPUT 1

OPTIONAL

PR

A1

B1

A2 A3

B

2 B3

CONTINUOUSLY

MONITORED

INTERMITTENTLY

MONITORED

FIELD INSTALLED

SAFETY DEVICES

NOTE:

SHOWN WITH SHORTING

BARS REMOVED AND ATTACHED

DEVICES IN NON-ALARM STATE.

CONTINUOUS INTERMITTENT

COM

COM

FAIL

OK

OK

FAIL

HIGH/LOW GAS, AUX. HI-LIMIT

AUX. LIMITS , EXT. FLOW SWITCH

EXAMPLE DEVICES:

BK

10

9

8

1

3

4

5

6

7

2

2

9

4 7

5

6

4

2

3

4

2

3

STAGE #1

STAGE #3

STAGE #2

STAGE #4

PR

BR

1

2

6

5

4

3

OUTLET

BR

BR

PR

PR

PR

24VAC

PI

RESET

PS

FF

TH

24COM

MV

M/S

1

2

4

5

6

7

8

9

11

3

10

24VAC

PI

RESET

PS

FF

TH

24COM

MV

M/S

1

2

4

5

6

7

8

9

11

3

10

-

+

LOW

HIGH

-

+

STATUS

-

+

BL/W

8

9

7

6

4

5

4

1

3

6

5

T

6

P-SW#1

IGN#1-PS

IGN#2-PS

P-SW#2

-24VAC

Y

Y

O/

BK

~~

~~

~~

~~

~~

~~

~

~

~

~

~

~

3

4 1

PROVING RELAY

BL

TE

R

M

IN

A

L

ST

R

IP

IGNITION

MODULE

#1

IGNITION

MODULE

#2

ALARM

INPUT 2

PR/BK

PR

P

BL/BK

GY/W

GY/W

GY/

W

SYSTEM/TANK

O.A.

SENSOR

FLAME

CURRENT

TEST PINS

FLAME

CURRENT

TEST PINS

RT1

RT2

BK

W

W

BK

GY

GY

BR/W

2

BL/

BK

PUMP OPTIONAL

ON BOILERS

BL

WARNING:

THIS HEATER MAY BE

CONNECTED TO ONE OR MORE BRANCH

CIRCUITS. TO PREVENT ELECTRICAL SHOCK,

ENSURE ALL BRANCH CIRCUITS ARE DE-

ENERGIZED BEFORE ATTEMPTING TO SERVICE

THIS EQUIPMENT.

OPTIONAL

BOILER ONLY

INLET

R/BK

R

R/W

2

RESET

OVERRIDE

3

HEAT

DEM

#2

R/

O

FIELD

INSTALL AS

NECESSARY

C

N.O.

REMOVE

JUMPER

STRIP REQUIRE THE REMOVAL OF SOME OF THE SHORTING BARS FROM THE TERMINAL STRIP.

NO TE :

SO ME STAG ES HAVE

MO RE THAN O NE G AS VALVES .

R

R

PR/BK

1

3

8

BL/BK

5

1

5

1

BL

Y

Y

OPTIONAL

PR

FFR

P

PR

AL

Y

P

Y

G

PR

PR

= LEDS LO CATED O N DISPLAY BO ARD

~~~~

~~~~

= O PTIO NA L DIN RAIL CO NNECTO RS

LO CATED IN ELECTRICAL W IRING BO X .

GND

C

C

NO

NO

PR

OPTIONAL HIGH-LOW GAS

PRESSURE SWITCHES

PR

LOW

HIGH

O/BK

INTERMITTENT

ALARM ENABLE

RELAY

C

C

NO

NO

C

NO

C

NO

C

NO

C

NO

W

TO POWER

SOURCE

RESET

O

BL/BK

BL

Y

PR

PR

T