Installation and service manual, Gas train and controls – Lochinvar 399 User Manual

Page 29

Installation and

Service Manual

29

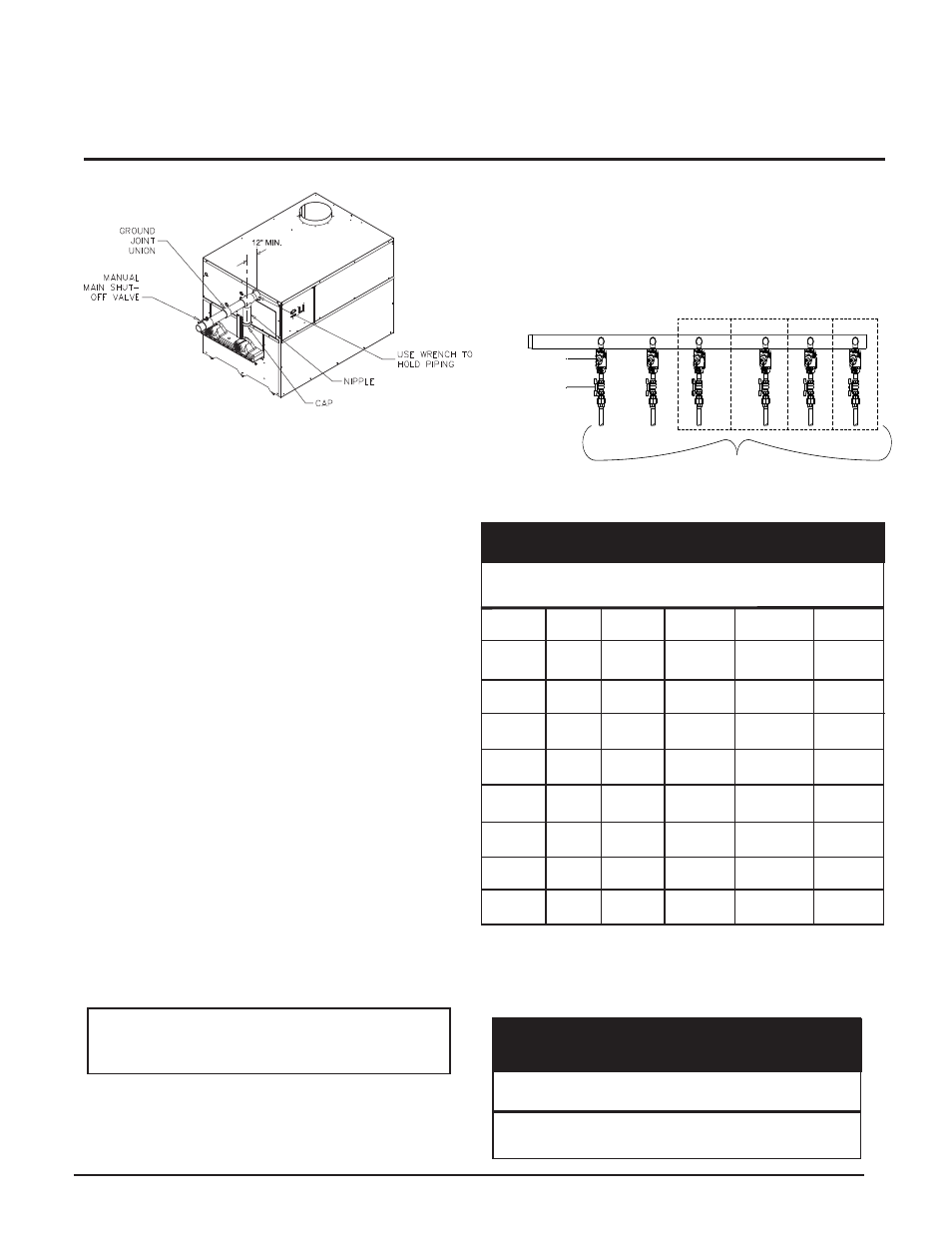

FIG. 28 Gas Line Connection

2. Use new, properly threaded black iron pipe free from

chips. If you use tubing, make sure the ends are cut square,

deburred and clean. Make all tubing bends smooth and

without deformation. Avoid flexible gas connections.

Internal diameter of flexible lines may not provide unit

with proper volume of gas.

3. Install a manual main gas shutoff valve at the unit’s gas

inlet, outside of the unit.

4. Run pipe or tubing to the unit’s gas inlet. If you use tubing,

obtain a tube to pipe coupling to connect the tubing to the

unit’s gas inlet.

5. Install a sediment trap in the supply line to the unit’s gas

inlet (see FIG. 28).

6. Apply a moderate amount of good quality pipe compound

(do not use Teflon tape) to pipe only, leaving two end

threads bare.

7. Remove seal over gas inlet to unit.

8. Connect gas pipe to inlet of unit. Use wrench to support

gas manifold on the unit.

9. For L.P. gas, consult your L.P. gas supplier for expert

installation.

10. Ensure that all air is completely bled from the gas line

before starting the ignition sequence. Start up without

properly bleeding air from the gas line may require

multiple reset functions of the ignition control module to

achieve proper ignition.

Gas Train and Controls

Note: The gas train and controls assembly provided on this unit

have been tested under the applicable American National

Standard to meet minimum safety and performance criteria

such as safe lighting, combustion and safety shutdown

operation.

FIG. 29 Typical Boiler Gas Train Drawing

For each elbow or tee, add equivalent straight pipe to total length from table

below.

Figure 29 on this page shows a typical boiler gas train.

ƽ

WARNING: Do not have any open flame

in proximity to the gas line when bleeding air

from the gas line. Gas may be present.

Btu/hr

Distance From Meter (in feet)

Input

0-50

51-100

101-200

201-300

301-500

399,999

1 1/4

"

1 1/4

"

1 1/2

"

2

"

2

"

500,000

1 1/4

"

1 1/2

"

2

"

2

"

2 1/2

"

650,000

1 1/2

"

2

"

2

"

2 1/2

"

2 1/2

"

750,000

1 1/2

"

2

"

2

"

2 1/2

"

3

"

990,000

2

"

2

"

2 1/2

"

2 1/2

"

3

"

1,260,000

2

"

2 1/2

"

2 1/2

"

3

"

3

"

1,440,000 2 1/2

"

2 1/2

"

3

"

3

"

3 1/2

"

1,800,000 2 1/2

"

3

"

3

"

3 1/2

"

3 1/2

"

2,070,000 2 1/2

"

3

"

3

"

3 1/2

"

4

"

TABLE-J

Suggested Gas Pipe Size for Single Unit Installations

Diameter Pipe (inches)

3/4

1

1 1/4

1 1/2

2

3

4

5

Equivalent Length of Straight Pipe (feet)

2

2

3

4

5

10

14

20

TABLE-K

Fittings to Equivalent Straight Pipe

COMBINATION VALVE

DOWNSTREAM

TEST VALVE

TO BURNERS

ADDITIONAL VALVES BASED

ON UNIT INPUTS