Installation, Boiler system piping, Continued – Lochinvar 399 User Manual

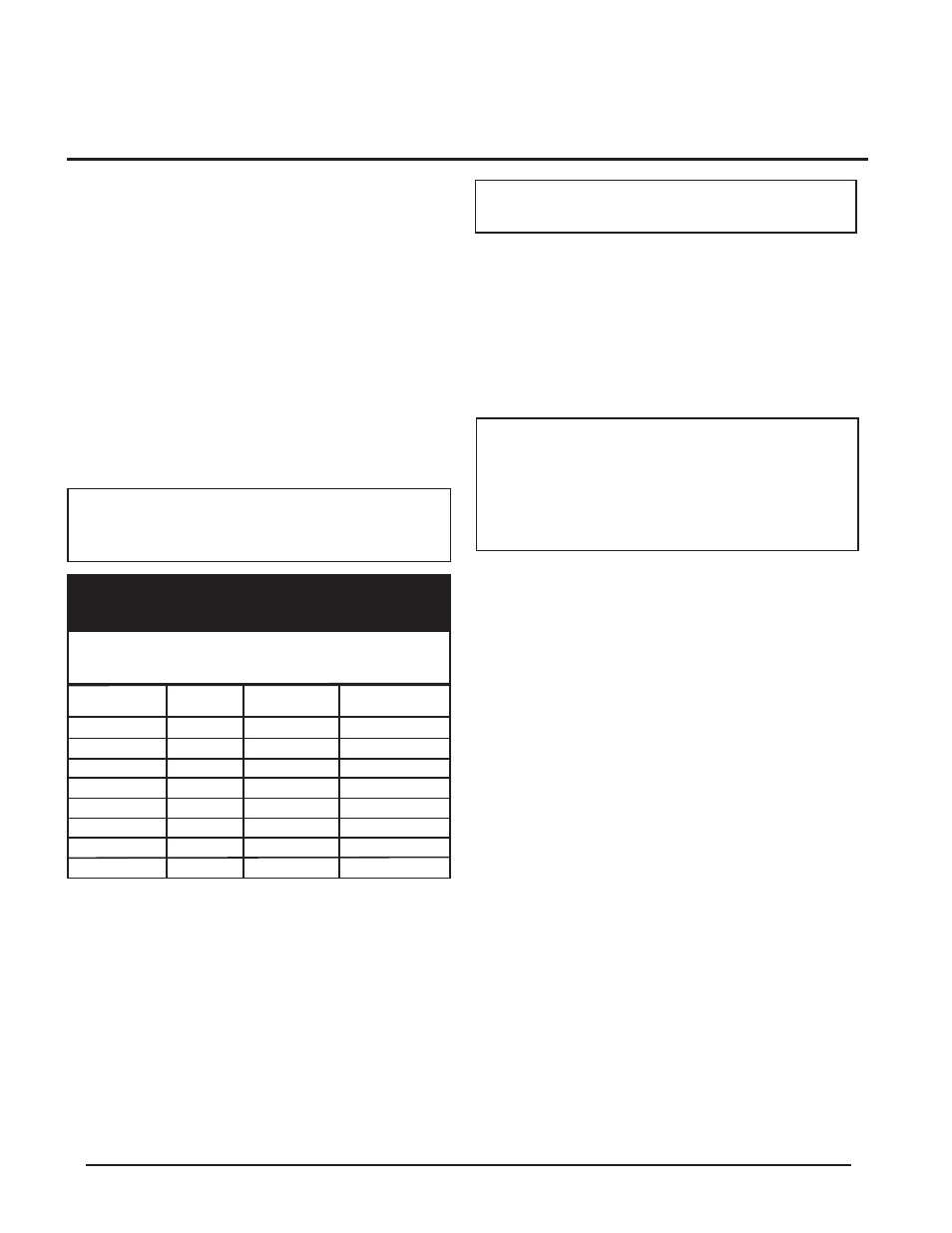

Page 34: Table-n amp draw data important

Hydronic Heating Boilers and

Domestic Water Heaters

34

INSTALLATION

Continued

1. Use only Type-T wire [63°F (35°C) rise] on all wiring

between the unit and field-installed devices.

2. Enclose line voltage wire exterior to the unit in approved

conduit or approved metal-clad cable.

3. The pump must run continuously when unit is being fired

(hot water heating boilers must use the optional pump

delay if the pump is to be cycled. See Freeze Protection,

page 7 when cycling the pump). Water heaters use the

pump delay as standard in accordance with ASHRAE 90.1

requirements.

4. To avoid serious damage, do not energize the unit until the

system is filled with water.

5. Provide the unit with proper overload protection.

BOILER SYSTEM PIPING

The drawings in this section show typical boiler piping

installations. Before beginning the installation, consult local

codes for specific plumbing requirements. Be sure to provide

unions and valves at the boiler inlet and outlet so it can be

isolated for service. You must install an air separation device in

the installation piping to eliminate trapped air in the system.

Locate a system air vent at the highest point in the system. The

system must also have a properly sized expansion tank

installed. Typically, an air charged diaphragm-type

compression tank is used. You must install the expansion tank

close to the boiler and on the suction side of the system pump

to ensure proper operation.

Provide suitable hangers or floor stands to support hot

water piping. The boiler alone should not support hot water

piping. Copper pipe systems are subject to considerable

expansion and contraction. Rigid pipe hangers could allow the

pipe to slide in the hanger resulting in noise transmitted into

the system. Use padding on rigid hangers installed with a

copper system. Pipe the boiler pressure relief valve to a

suitable floor drain. See the relief valve section in this manual.

General Plumbing Rules

1. Check all local codes.

2. For serviceability of boilers, always install unions.

3. Always pipe the pressure relief valve to an open drain.

4. Locate system air vents at the highest point of the system.

5. Expansion tank must be installed near the boiler and on

the suction side of the pump.

6. Support all water piping.

Water Connections: Heating Boilers Only

The 399,999 - 750,000 boilers have 2" NPT inlet and outlet

connections whereas the 990,000 - 2,070,000 boilers have

2 1/2" NPT inlet and outlet connections. Note: Field-installed

reducing bushings may decrease flow resulting in boiler noise

or flashing to steam.

Circulator Pump Requirements

This is a low mass, high efficiency hot water boiler which must

have adequate flow for quiet, efficient operation. Pump

selection is critical to achieve proper operation. A pump should

be selected to achieve proper system design water temperature

rise. A heat exchanger head-loss chart (FIG.’s 34 and 35) is

provided to assist in proper pump selection. Also provided is a

System Temperature Rise Chart (TABLE–P, page 37). This

table provides GPM and boiler head-loss at various

temperature rises for each boiler based on Btu/hr input.

Temperature rise is the difference in boiler inlet temperature

and boiler outlet temperature while the boiler is firing.

Btu/Hr

Approximate

Input

Controls

Fans Total Amps

399,999

3.6

2.7

6.3

500,000

3.6

2.7

6.3

650,000

5.4

3.4

8.8

750,000

5.4

3.4

8.8

990,000

7.3

3.2

10.5

1,260,000

7.3

3.2

10.5

1,440,000

7.3

6.7

14.0

1,800,000

7.3

6.7

14.0

2,070,000

7.3

6.7

14.0

TABLE-N

AMP Draw Data

IMPORTANT:

Do not block access to the

electrical cover plate when installing electrical

conduit.

ƽ

CAUTION: This boiler system should not

be operated at less than 12 PSIG.

ƽ

CAUTION: A leak in a boiler “system” will

cause the “system” to intake fresh water

constantly, which will cause the tubes to

accumulate a lime/scale build up. This will

cause a non-warrantable failure.