Installation and service manual, Gas manifold pressure adjustment – Lochinvar 399 User Manual

Page 31

Installation and

Service Manual

31

Check burner performance by cycling the system while you

observe burner response. Burners should ignite promptly.

Flame pattern should be stable, see Burner Flames, page 56.

Turn system off and allow burners to cool, then cycle burners

again to ensure proper ignition and flame characteristics.

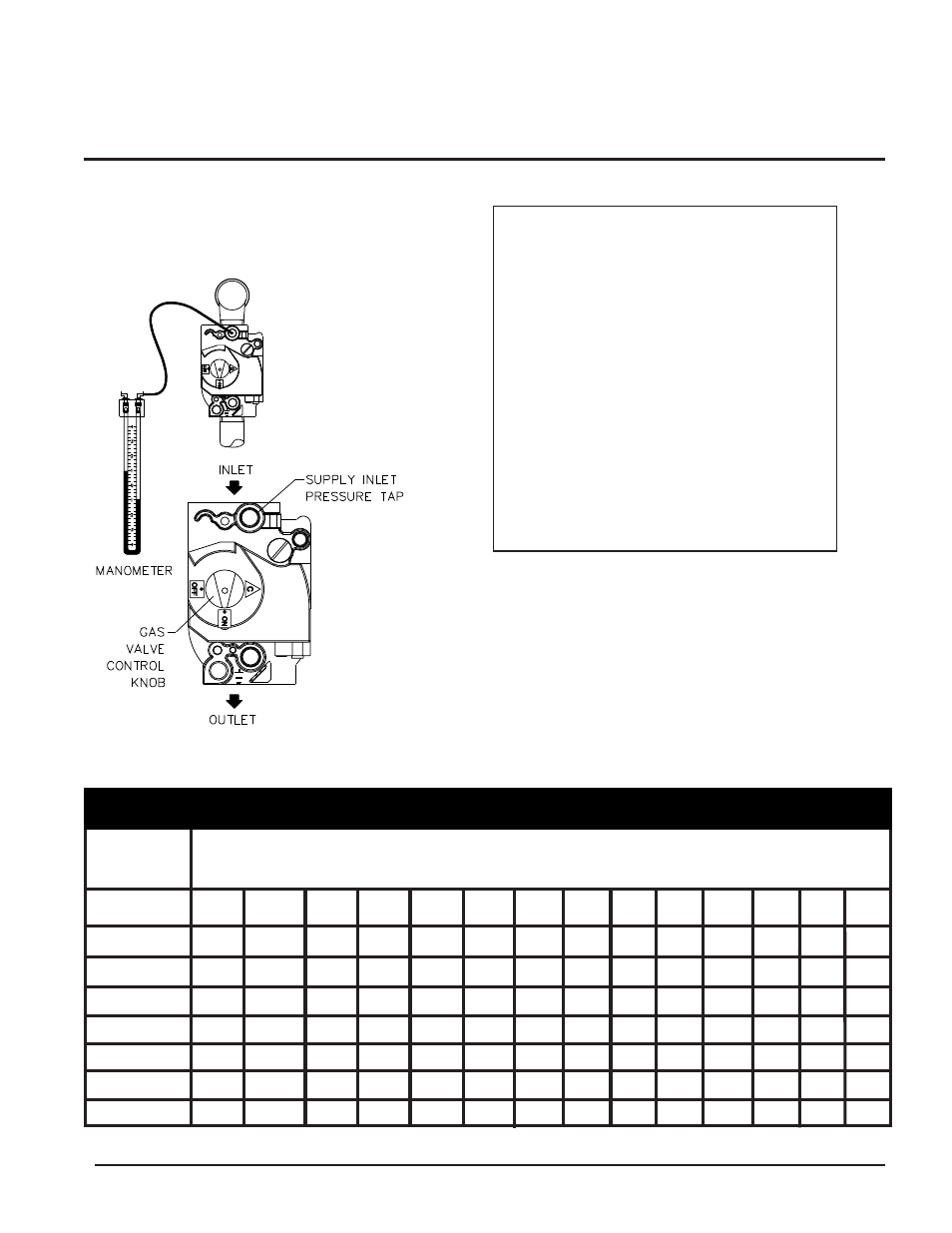

FIG. 30 Measuring Gas Supply Pressure at Combination

Gas Valve

Gas Manifold Pressure Adjustment

1. Loosen knurled knob that fastens the control panel access

door and pull out control panel.

2. Turn the power switch located in the lower left corner

behind the control panel access door to the “O” or “OFF”

position.

3. Remove the top front jacket access panels to access the gas

valves.

Nominal Iron

Length of Pipe In Straight Feet

Pipe Size,

(Inches)

10

20

30

40

50

60

70

80

90

100

125

150

175

200

TABLE - L

Multiple Unit Installations Gas Supply Pipe Sizing

3/4

"

369

256

205

174

155

141

128

121

113

106

95

86

79

74

1"

697

477

384

328

292

267

246

256

210

200

179

164

149

138

1 1/4

"

1,400

974

789

677

595

543

502

472

441

410

369

333

308

287

1 1/2

"

2,150

1,500

1,210

1,020

923

830

769

707

666

636

564

513

472

441

2"

4,100

2,820

2,260

1,950

1,720

1,560

1,440

1,330

1,250

1,180

1,100

974

871

820

2-1/2"

6,460

4,460

3,610

3,100

2,720

2,460

2,310

2,100

2,000

1,900

1,700

1,540 1,400

1,300

3"

11,200

7,900

6,400

5,400

4,870

4,410

4,000

3,800

3,540

3,300

3,000

2,720 2,500

2,340

4"

23,500

16,100

13,100

11,100

10,000

9,000

8,300

7,690

7,380

6,870

6,150

5,640 5,130

4,720

Maximum capacity of pipe in thousands of BTU’s per hour for gas pressures of 14 Inches Water Column (0.5 PSIG) or less and a total system

pressure drop of 0.5 Inch Water Column (Based on NAT GAS, 1025 BTU’s per Cubic Foot of Gas and 0.60 Specific Gravity).

IMPORTANT: The gas valves are

referenced to the fan pressurized

chamber by a hose connected from the

vent of the gas valve regulator to the

chamber pressure tap located on the front

inside portion of the jacket. Reference the

drawings in this section for component

and connection points for pressure

measurement. The procedure for

connecting a manometer or magnehelic

must be followed to obtain actual net

manifold pressure for normal operation. A

manometer or magnehelic gauge legible

in 0.1" increments up to 10 inches w.c. is

required to check and adjust the manifold

pressure. The regulator cover screw on

the gas valve must be in place and tight at

all times for the unit to operate properly.