Installation, Continued, Connecting to gas supply – Lochinvar 399 User Manual

Page 28: Gas pressure test, Gas piping, Connecting gas piping to unit

Hydronic Heating Boilers and

Domestic Water Heaters

28

INSTALLATION

Continued

CONNECTING TO GAS SUPPLY

Only supply gas type specified on the unit’s rating plate. This

unit is orificed for operation up to 2000 feet altitude. If

installing above 2000 feet elevation, consult the appliance

manufacturer.

INLET PRESSURE: Measure inlet pressure at the inlet

pressure tap located upstream of the combination gas valve(s).

See TABLE–I for maximum and minimum inlet pressures. Do

not exceed the maximum. Minimum inlet pressure is for the

purpose of input adjustment.

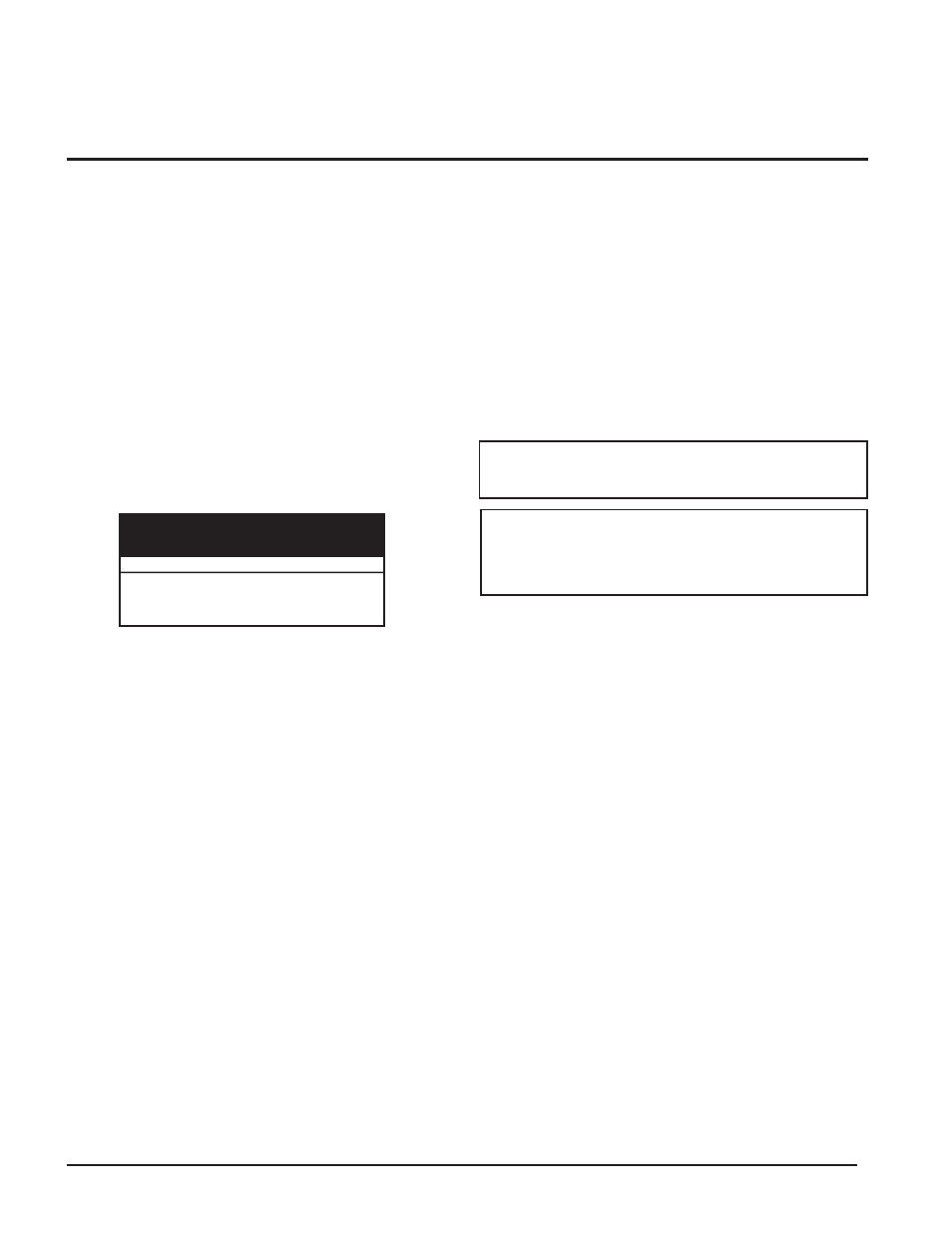

TABLE–H

Inlet P

MANIFOLD PRESSURE: Measure manifold pressure at the

pressure tap on the downstream side of the combination gas

valves. The gas regulator on the unit’s combination gas valve is

adjustable to supply proper manifold pressure for normal

operation. See TABLE–M, page 32 for net manifold pressure

settings.

If you must adjust regulator pressure, follow the instructions

under Gas Manifold Pressure Adjustment, page 31. Do not

increase regulator pressure beyond specified pressure setting.

Gas Pressure Test

1. Disconnect unit from the gas supply piping system during

any piping system pressure testing greater than 1/2 PSIG

(3.5kPa).

2. Isolate the unit from the gas supply piping system by

closing a manual shutoff valve during any piping system

pressure testing that is equal to or less than 1/2 PSIG

(3.5kPa).

3. Test all gas connections for gas leaks before placing unit in

operation.

Gas Piping

To safely operate this unit, you must properly size the gas

supply piping. See TABLES-J, K, & L for piping and fitting

requirements. Gas pipe size may be larger than heater

connection.

For ease of service, install a union.

Install a manual main gas shutoff valve, outside of the unit gas

connection within six feet of the unit in accordance with the

requirements of the National Fuel Gas Code, ANSI Z223.1.

You must provide a sediment trap (drip leg) in the inlet of the

gas connection to the unit.

The combination gas valves have an integral vent limiting

device and do not require venting to atmosphere, outside the

building. The unit will not operate properly if the reference

hose is removed or a vent to atmosphere is installed.

Optional gas controls may require routing of bleeds and vents

to the atmosphere, outside the building when required by local

codes.

Connecting Gas Piping to Unit

All gas connections must be made with pipe joint compound

resistant to the action of liquefied petroleum (L.P.) and natural

gases. All piping must comply with local codes and ordinances.

Piping installations must comply with approved standards and

practices.

1. Make sure gas line is a separate line direct from the meter

unless the existing gas line is of sufficient capacity. Verify

pipe size with your gas supplier.

Max.

Min.

Nat. Gas

10.5" w.c.

4.5" w.c.

LP Gas

13" w.c.

8" w.c.

TABLE-I

Inlet Pressure

NOTE: It is the installer’s responsibility to supply

the sediment trap (drip leg).

IMPORTANT: Do not block access to the electrical

cover plate when installing the sediment trap. The

sediment trap must be a minimum of 12 inches

from the appliance.