3 operation, 1 conveyance speed control, 2 synchronizing roller control – Konica Minolta 5430 DL 5440 DL 5450 User Manual

Page 124: 3 operation -87, 1 conveyance speed control -87, 2 synchronizing roller control -87

Main Unit Theory of Operation

Conveyance Section

2-87

II Comp

osition

/O

p

eration

15.3 Operation

15.3.1

Conveyance speed control

• The Intermediate Transport Motor (M3) provides drive for the conveyance section.

• The conveyance speed is variable in three steps and the appropriate one is selected

according to the media type and print mode as detailed below.

• For the first print, the machine makes the above decision before starting a print/media

feed sequence and, based on the established speed, starts the print/media feed

sequence.

15.3.2

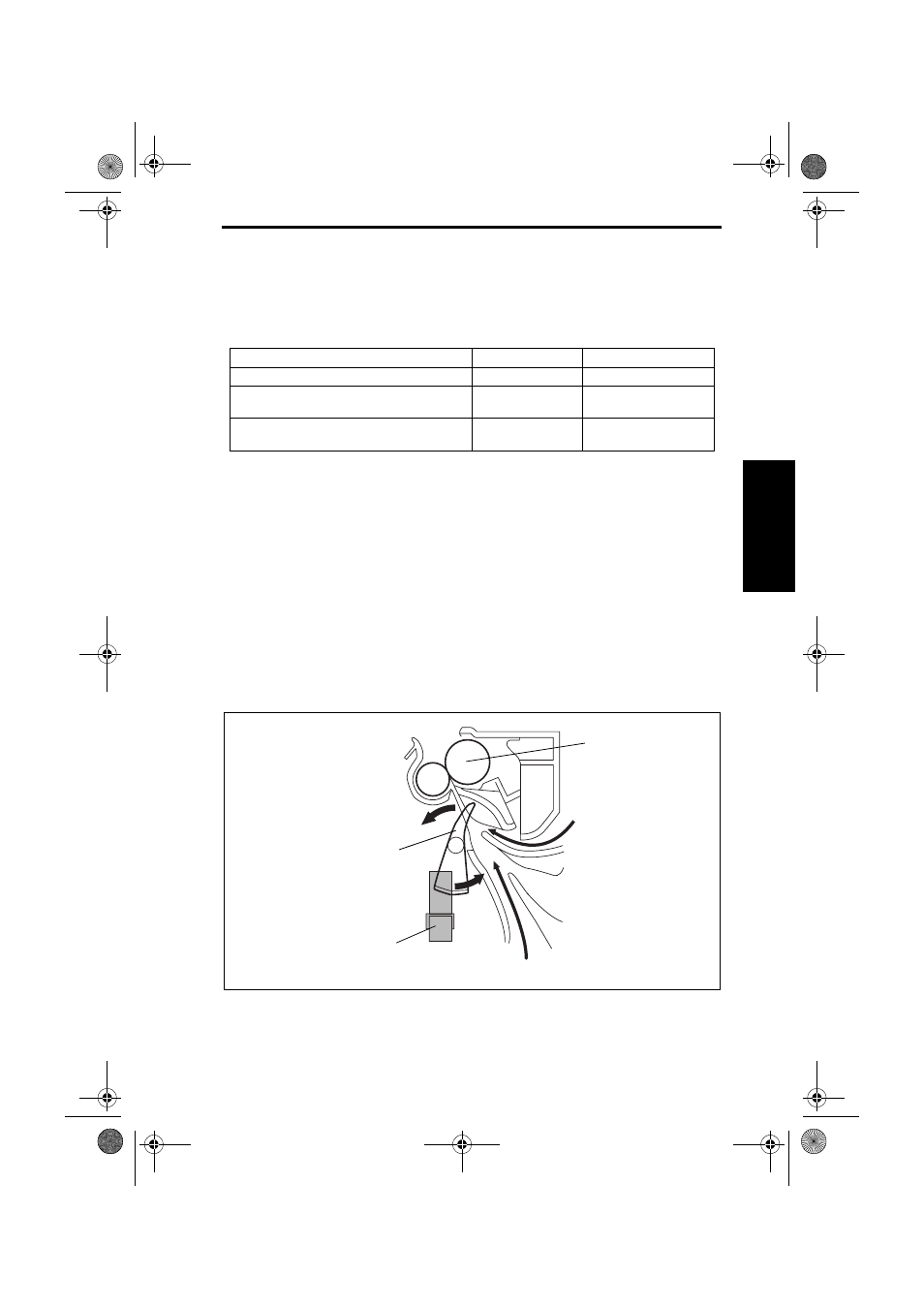

Synchronizing Roller control

• When the media taken up and fed in by the Feed Roller reaches the Synchronizing

Roller, a loop is formed in the media and media conveyance is temporarily stopped. Con-

veyance skew is corrected by this loop.

• The Synchronizing Roller Sensor (PC4) detects whether or not the media has reached

the Synchronizing Roller.

• The media fed in is synchronized with the image before media conveyance is restarted.

A. Media detection control

• When the media fed from the Feed Roller pushes up the actuator of the Synchronizing

Roller Sensor (PC4), the sensor is unblocked. With this event occurring, the machine

determines that the media has reached the position before the Synchronizing Roller.

Media type/print mode

Conveyance speed

Reason

Plain paper

1 (standard)

Thick stock, envelopes, postcards, label OHP film

(monochrome print)

1/2 (one-half speed)

To ensure good fusing

performance

OHP film (color print)

1/3 (one-third speed)

To ensure good light

transmission performance

4138to2099c0

Synchronizing Roller

Paper (fed from Duplex)

Media (from Tray 1/2/3)

Synchronizing Roller Sensor

(PC4)

Actuator

5430DL_5440DL_5450_TO_PDF.book 87 ページ 2005年4月12日 火曜日 午後4時49分