Direct venting - for gpv models – State GPG/GPV-540A User Manual

Page 9

9

DirECT VENTiNG - FOr GPV MODELS

All exhaust vent terminal, flue reducer, and intake vent terminal

are supplied with any unit intended for direct venting. These parts

must be installed without alteration.

This heater is category III appliance when used in a direct

vent application. All national and local codes pertaining to the

installation of such an appliance must be followed.

Horizontal portions of the exhaust vent system must be installed

with a minimum upward slope of 1/4” (6.35 mm) per foot of

length.

Selkirk metalbestos model PS or G vent is approved for use as

exhaust venting on these models. Model PS is a double-wall

vent with a 1” (25.4 mm) air space between pipes. Model G is

a single-wall variation of model PS for use where combustible

clearance is not a concern, see Table 4.

TABLE 4.

Selkirk Metalbestos Model PS

Clearance to Combustibles

Interior

6” (152.4 mm)

Exterior

6” (152.4 mm)

8” diameter PVC or galvanized pipe is approved for use as

intake venting on these models. Class 63, 100, 125, 200, and

schedule 40 pipe may be used for PVC pipe. Intake venting

must be adequately supported to avoid unnecessary stress on

vent hood, venting, or burner.

See Table 5 limitations on venting system design for direct vent

installations.

TABLE 5.

Dimension in

GPV

inches (mm)

540A -740A

Flue Outlet Dia.

9 (229)

Flue Reducer Dimension

9 x 8

(Supplied)

(229 x 203)

Min. Exhaust Vent Dia. Inch (mm)

8 (203)

Min. Intake Vent Dia. Inch (mm)

8 (203)

Maximum Number Of

90°

4

Elbows, Intake

45°

8

Maximum Number Of

90°

4

Elbows, Exhaust

45°

8

Total Intake Vent

Max.

75 (23 m)

Length, Equiv. Ft.

Min.

3 (1 m)

Total Exhaust Vent

Max.

75 (23 m)

Length, Equiv. Ft.

Min.

6 (1.8)

Note: Barometric draft control is not used in direct vent installations

as the venting system must be sealed.

When calculating the equivalent length of a venting system each

90 elbow is equivalent to 10 feet of straight pipe. Each 45 elbow

is equivalent to 5 feet (1.5 m) of straight pipe. Do not exceed the

maximum number of elbows as shown in Table 5. In no case may

the sum of the straight pipe lengths and the equivalent lengths of

the elbows exceed the valves in Table 5.

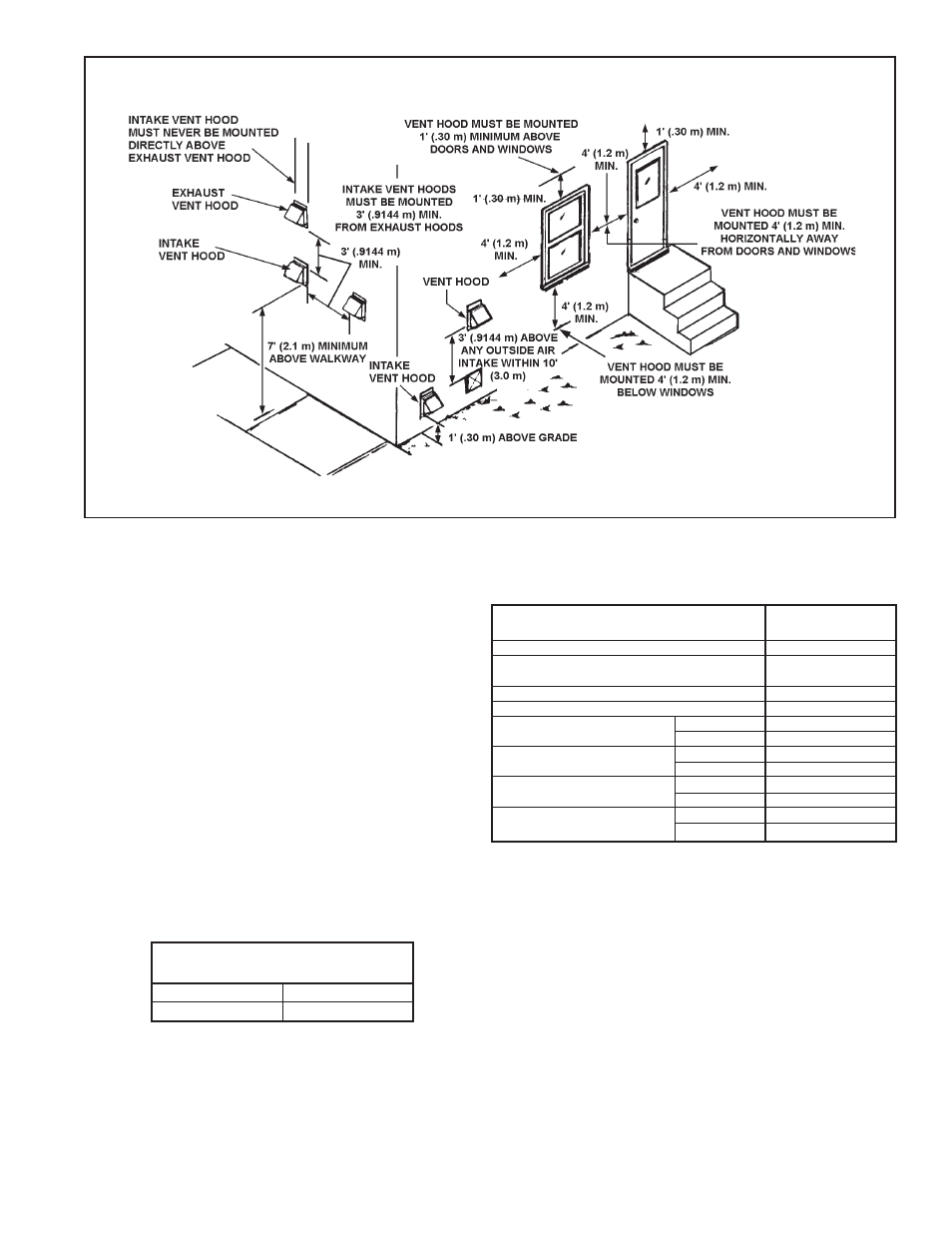

VENT TErMiNAL LOCATiONS-EXHAUST

See “Horizontal Venting” in this manual for acceptable locations

for exhaust hoods.

VENT TErMiNAL LOCATiONS-iNTAkE

When considering locations for the intake terminal, bear in mind

that the terminal:

FiGUrE 6.