State GPG/GPV-540A User Manual

Page 8

8

Refer to Table 2 for limitations of venting system design for

horizontal venting.

TABLE 2

GPV-540A-740A

Flue Outlet Dia. (Inches/mm)

9” (228.6)

Flue Reducer

9” x 8”

Dimensions -Supplied (Inches/mm)

228.6 x 203.2

Minimum Outlet Vent Dia. (Inches/mm)

8” (203.2)

Maximum Number

90°

4

Of Elbows

45°

8

Maximum Total Vent System

75

Length, Equiv. Feet/Meters

(23 m)

When calculating the equivalent length of a venting system each

90° elbow is equivalent to 10 feet (3 m) of straight pipe. In no case

45° elbow is equivalent to 5 feet (1.5 m) of straight pipe. In no

case may the sum of the straight pipe lengths and the equivalent

length of the elbows exceeds 80 feet (24.3 m).

Note the minimum vent diameter in Table 2.

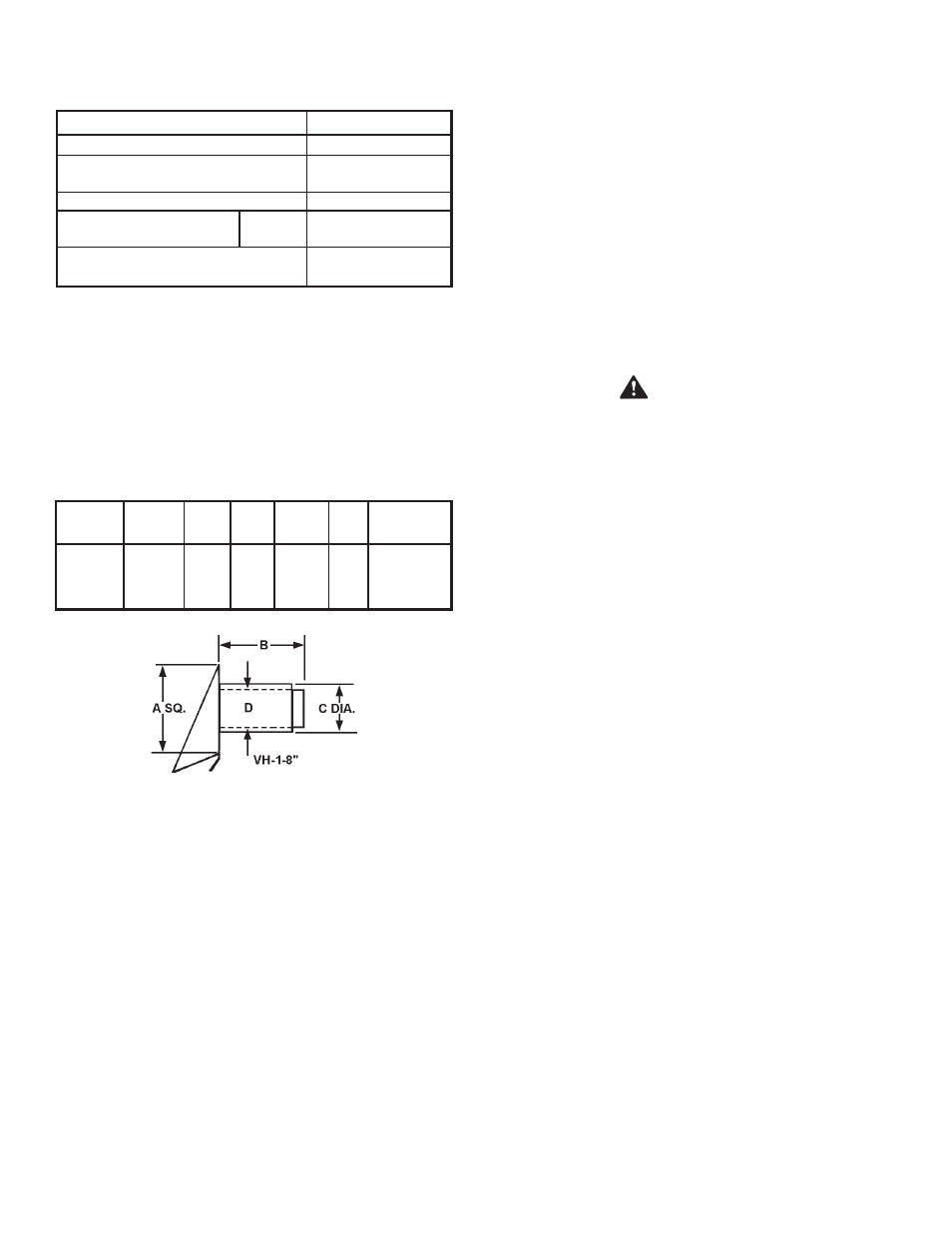

Refer to Table 3 for the correct vent terminal size for each heater.

The dimensions noted in Table 3 refer to Figure 5.

TABLE 3

Heater Terminal

rough-in

Model

Model

A

B

C

D Dimensions

GPV

540A-

VH-1-8” 19-7/8” 13” 10-9/16” 8-5/8”

11-1/16”

740A

FiGUrE 5

Use only the sidewall vent terminal supplied with the heater.

These terminals are specifically listed for use on these

State heaters.

VENT TErMiNAL LOCATiONS-EXHAUST

When considering location for sidewall vent terminals refer to the

latest edition of the National Fuel Gas Code which recommends

that vent terminals:

1. Shall be located not less than 12” (304.8 mm) above grade.

2. Shall be located not less than 7 feet (2.1 m) above grade when

adjacent to a public walkway.

3. Shall terminate at least 3 feet (0.9 m) above any forced air inlet

within 10 feet (3 m).

4. Shall terminate at least 4 feet (1.2 m) below, 4 feet (1.2 m)

horizontally from or 1 foot above any door, window or gravity

air inlet into any building.

5. Shall not be closer than 3 feet (0.9 m) from the inside corner

of an L- shaped structure.

6. Shall be located above the snow line in geographical areas

where snow accumulates.

VENT SySTEM iNSTALLATiON

This heater is a category III appliance when horizontally vented

through a wall using the supplied sidewall vent terminal. All

national and local codes pertaining to the installation of such

venting systems must be followed.

Horizontal portions of the vent system must be installed with a

minimum upward slope of 1/4” per foot of length.

All joints and seams in the venting system must be sealed gas

tight. If a silicone sealer is used, it must have a continuous

temperature rating of at least 500°F (260°C); Dow Corning

736 or equivalent must be used.

CAUTiON

Use only the vent hood supplied with this kit. Only supplied

hood provides required clearances from combustibles, both

through the wall and the exterior siding. Termination of a

sidewall vent system with a device other than the supplied

vent hood could affect system performance and result in a

safety hazard.

iMPOrTANT

Plan the layout of the vent system backward from the vent

termination to the water heater.

1. Use the layout of the vent system backward from the vent

termination to the water heater.

BEwArE OF CONCEALED wiriNG AND PiPiNG iNSiDE

OF wALL. rEFEr TO TABLE 5 FOr THE MAXiMUM wALL

THiCkNESS “B” FOr EACH MODEL.

2. Slide hood through opening from outside. Fasten hood to

exterior wall with anchors and screws supplied.

3. Install covers plate and fasten to inside wall with 4 screws.

4. Attach a seal ring (Meltalbestos SR or equivalent) to the

vent hood collar, see Figure 7. Attach Selkirk Metalbestos

model PS or model G venting to the seal ring following the

venting manufacturer’s instructions. For total safety, it is

recommended that only venting listed for use with category

III appliances (positive vent pressure, non-condensing)

should be used between the heater and the vent hood, even

through national or local codes may allow the use of type B

or single-wall vent.

5. Install the remaining vent sections back to the heater, following

the venting manufacturer’s instructions on assembling and

sealing joints. Follow good venting practice regarding properly

supporting vent system and keeping the number of offsets to

a minimum. See Table 2 for the maximum allowable number

of elbows in venting system.

6. Install the flue reducer included with the exhaust hood between

the vent system and the heater.

7. Seal all vent connections and venting with sealants supplied

by vent pipe manufacturer or with a high-temperature silicone

sealant suitable for continuous temperatures of 500°F

(260°C). Acceptable sealant include Dow Corning 736

or equivalent.