General information, Maintenance, Power burner – State GPG/GPV-540A User Manual

Page 27: Thermostat, High limit, General, Maintenance schedule, Electrical servicing, Flushing

27

GENErAL iNFOrMATiON

POwEr BUrNEr

The initial start-up procedure of the gas power burner is provided

on page 18 thru 21. Refer to Figure 12, burner exploded view for

burner components location.

The sequence of operation of the power burner is provided on

page 15. For detailed Power Burner Operation, Maintenance

and Troubleshooting refer to the separate Power Burner Manual

provided with this water heater.

THErMOSTAT

It is suggested the thermostat be turned to the lowest setting,

which satisfies the hot water requirements of the system. This

helps minimize scale formation in the heater.

HiGH LiMiT

The high limit (not adjustable) is factory set to cutout at 205°F

(96°C). The high limit switch must be manually reset by depressing

the reset button on front of the control when water temperature

drops to about 180°F (82°C).

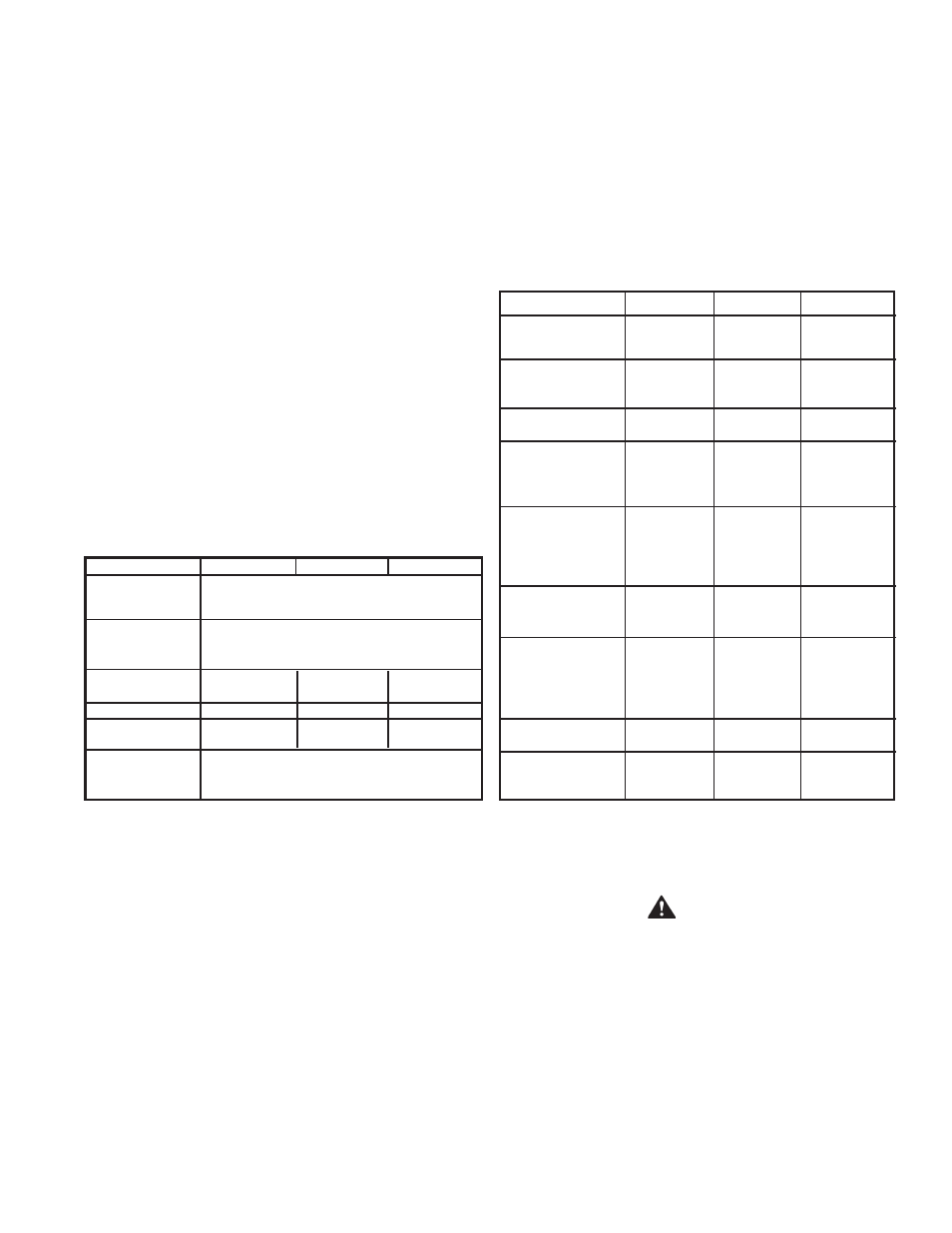

GAS AND Air SUPPLy SPECiFiCATiONS TABLE 10

Model

GPG/GPV-540A GPG/GPV-650A GPG/GPV-750A

Min. Dynamic Gas

Supply Line 8” w.c. (2 kPa) When heater is ON

Pressure

Max. Static Gas

Supply Line 14” w.c. (3.5 kPa) When heater is OFF

Pressure

Gas Manifold

Pressure

Gas Orifice Size

1/2”

11/16”

N/A

Air Inlet Damper

Dial Setting

Combustion

Emissions

Range

* Note: Flue gas excess O

2

below 3% may cause combustion

chamber premature failure; flue gas excess O

2

above 7%

may cause rough operation or incomplete combustion. Final

manifold pressure settings should be based on flue O

2

/CO

2

reading!

**

Note: Air inlet damper setting needs to be adjusted at field for

direct vent and/or high elevation installations.

MAiNTENANCE

GENErAL

kEEP APPLiANCE ArEA CLEAr AND FrEE FrOM COMBUSTiBLE

MATEriALS, GASOLiNE AND OTHEr FLAMMABLE VAPOrS

AND LiQUiDS. (SEE wArNiNG PAGE 6).

Water heater maintenance includes periodic tank flushing and

cleaning, and removal of lime scale. The power burner should

be inspected and adjusted to maintain proper combustion. Refer

to the following table. A periodic inspection of the venting system

should be made. Where used the water heating system circulating

pump should be oiled.

MAiNTENANCE SCHEDULE

Following are the instructions for performing some of the

recommended maintenance. Power burner inspection and

adjustment should be performed by a competent technician.

MAiNTENANCE SCHEDULE

Component

Operation

interval

required

Sediment

Tank

Removal

Monthly

Flushing

Lime Scale

UN-LIME®

Removal

Semi-Annually

Delimer

Relief Valve

Inspect

Semi-Annually

SAE No. 20

Circulating Pump(1)

Oiling

Four Months non-detergent

motor oil

Clean Inlet

Power Burner Blower Screen and

As Required

Soft Brush

Blower Wheel

Power Burner and

Ignition Device(2)

Inspection Semi-Annually

Make sure gate

Barometric Damper

Inspect

Every 3

swings freely,

Months

no spillage

into room

Flue

Cleaning

As Required

Wire Brush

Every 3

Joints should

Vent System

Inspect

Months

be sealed

(1) If furnished with oiling provisions.

(2) If flange gasket is damaged, it must be replaced.

ELECTriCAL SErViCiNG

CAUTiON

LABEL ALL wirES PriOr TO DiSCONNECTiON wHEN

SErViCiNG CONTrOLS. wiriNG ErrOrS CAN CAUSE

iMPrOPEr AND DANGErOUS OPErATiON.

VEriFy PrOPEr OPErATiON AFTEr SErViCiNG.

FLUSHiNG

1. Turn off the heater electrical disconnect switch.

2. Open the drain valve and allow water to flow until it runs

clean.

3. Close the drain valve when finished flushing.

4. Turn on the heater electrical disconnect switch.

Flue Gas O2: 5 - 6.5%**

(or CO2 reading 8 - 9%)

4.7”w.c. (1.1 kPa)

(Ref.)*

4.7”w.c. 1.1 kPa)

(Ref.)*

4.7”w.c. (1.1 kPa)

(Ref.)*

4.5**

5.6**

3**