Gas meter size – city gases only, Gas pressure regulation, Gas valves – State GPG/GPV-540A User Manual

Page 12

12

TABLE 9A

MAXiMUM CAPACiTy OF PiPE iN CUBiC FEET OF GAS PEr HOUr

(Based upon a Pressure Drop of 0.5 inch water Column

and 0.5 specific Gravity Gas and max. gas press. of .5 psig)

LENGTH

iN

Nominal iron Pipe Sizes, Millimeters

METErS 1/2” 3/4” 1” 1 1/4” 1 1/2” 2” 2 1/2”

3”

4”

3.0

51 105 199 410

615

1160 1845

3221

6735

6.1

35

73 142 278

428

805 1277

2255

4626

9.1

28

59 110 225

346

644 1031

1830

3748

12.2

24

50

94

193

290

556

878

1552

3192

15.2

21

44

83

170

264

492

776

1391

2840

18.3

19

40

76

155

237

445

703

1259

2577

21.3

18

37

70

143

220

410

659

1142

2372

24.4

17

35

64

135

202

381

600

1083

2196

27.4

16

32

60

126

190

357

571

1010

2108

30.5

15

30

57

117

182

337

542

952

1962

38.1

13

27

51

105

161

299

483

864

1757

45.7

12

25

47

95

146

278

439

776

1610

53.3

11

23

42

88

135

249

401

717

1464

61.0

10

21

40

82

126

234

375

688

1347

wArNiNG

THE HEATEr iS NOT iNTENDED FOr OPErATiON AT HiGHEr

THAN 14” (3.5 kPa) wATEr COLUMN (1/2 POUND PEr SQUArE

iNCH) SUPPLy GAS PrESSUrE. HiGHEr GAS PrESSUrES

rEQUirE SUPPLEMENTAL rEDUCiNG SErViCE rEGULATiON.

EXPOSUrE TO HiGHEr GAS SUPPLy PrESSUrE MAy

CAUSE DAMAGE TO THE GAS CONTrOLS wHiCH COULD

rESULT iN FirE Or EXPLOSiON. iF OVErPrESSUrE HAS

OCCUrrED SUCH AS THrOUGH iMPrOPEr TESTiNG OF

GAS LiNES Or EMErGENCy MALFUNCTiON OF THE SUPPLy

SySTEM, THE GAS VALVE MUST BE CHECkED FOr SAFE

OPErATiON. MAkE SUrE THAT THE OUTSiDE VENTS ON

THE SUPPLy rEGULATOrS AND THE SAFETy VENT VALVES

ArE PrOTECTED AGAiNST BLOCkAGE. THESE ArE PArTS

OF THE GAS SUPPLy SySTEM, NOT THE HEATEr. VENT

BLOCkAGE MAy OCCUr DUriNG iCE STOrMS.

iT iS iMPOrTANT TO GUArD AGAiNST GAS VALVE FOULiNG

FrOM CONTAMiNANTS iN THE GAS wAyS. SUCH FOULiNG

MAy CAUSE iMPrOPEr OPErATiON, FirE Or EXPLOSiON.

iF COPPEr SUPPLy LiNES ArE USED THEy MUST BE

iNTErNALLy TiNNED AND CErTiFiED FOr GAS SErViCE.

BEFORE ATTACHING THE GAS LINE, BE SURE THAT ALL GAS

PIPE IS CLEAN ON THE INSIDE.

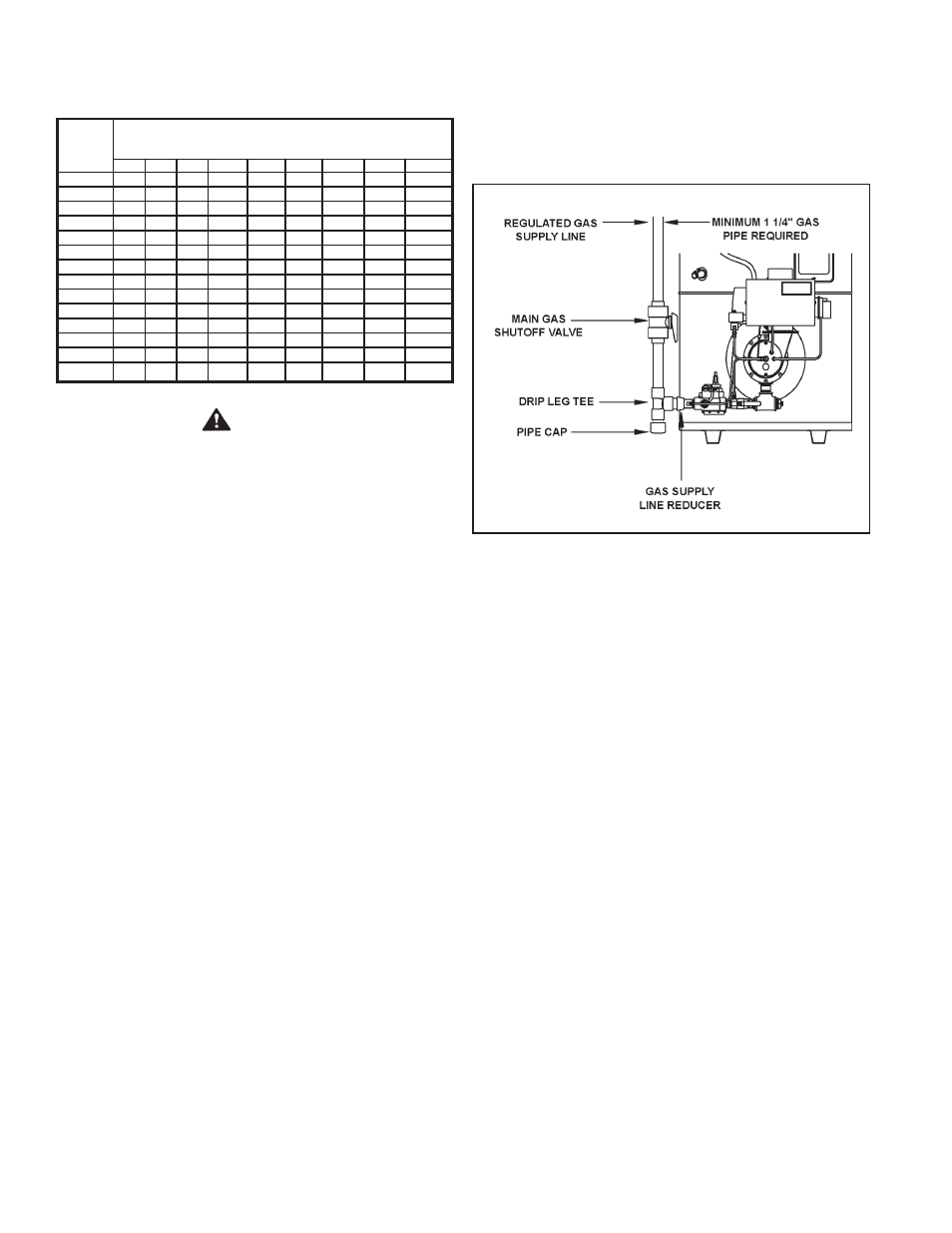

TO TrAP ANy DirT Or FOrEiGN MATEriAL iN THE GAS

SUPPLy LiNE, A DirT LEG (SOMETiMES CALLED A SEDiMENT

TrAP Or DriP LEG) MUST BE iNCOrPOrATED iN THE PiPiNG

(SEE FiG. 10) THE DirT LEG MUST BE rEADiLy ACCESSiBLE

AND NOT SUBJECT TO FrEEZiNG CONDiTiONS. INSTALL IN

ACCORDANCE WITH RECOMMENDATIONS OF SERVING GAS

SUPPLIERS. REFER TO THE NATIONAL FUEL GAS CODE.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply to gas valve inlet.

Apply joint compounds (pipe dope) sparingly and only to the

male threads of pipe joints. Do not apply compound to the first

two threads. Use compounds resistant to the action of liquefied

petroleum gases.

DiSCONNECT THE APPLiANCE AND iTS MANUAL GAS

SHUT-OFF VALVE FrOM THE GAS SUPPLy PiPiNG SySTEM

DUriNG ANy SUPPLy PrESSUrE TESTiNG EXCEEDiNG

1/2 PSiG. GAS SUPPLY LINE MUST BE CAPPED WHEN

DISCONNECTED FROM THE HEATER. FOR TEST

PRESSURES OF ½ PSIG OR LESS, THE APPLIANCE NEED

NOT BE DISCONNECTED, BUT MUST BE ISOLATED FROM

THE SUPPLY PRESSURE TEST BY CLOSING THE MANUAL

GAS SHUT-OFF VALVE.

GAS PiPiNG AND DirT LEG iNSTALLATiON

FiGUrE 9.

BEFOrE PLACiNG THE HEATEr iN OPErATiON, CHECk FOr

GAS LEAkAGE. USE SOAP AND WATER SOLUTION OR OTHER

MATERIAL ACCEPTABLE FOR THE PURPOSE IN LOCATING GAS

LEAKS.

DO NOT USE MATCHES, CANDLES, FLAME Or OTHEr

SOUrCES OF iGNiTiON FOr THiS PUrPOSE.

GAS METEr SiZE – CiTy GASES ONLy

Be sure that the gas meter has sufficient capacity to supply the

full rated gas input of the water heater as well as the requirements

of all other gas fired equipment supplied by the meter. If the gas

meter is too small, request the gas company to install a larger

meter having adequate capacity.

GAS PrESSUrE rEGULATiON

Main line gas pressure to the water heater should be between

8” w.c. (2 kPa) minimum (dynamic pressure or net pressure)

and 14” (3.5 kPa) maximum w.c. (static pressure). The inlet

gas pressure must not exceed the maximum value. A service

regulator is necessary if higher gas pressures are encountered,

see Table 10.

Due to pressure drop along gas supply line, to maintain

8” w.c. (2 kPa) minimum dynamic pressure, initial gas inlet pressure

must be set at higher than 8” w.c. (2 kPa). The gas regulator

must be properly sized to prevent unstable control or excessive

pressure drop.

GAS VALVES

Figure 10 shows the gas control valve that is supplied on

these heaters.