State GPG/GPV-540A User Manual

Page 7

7

Heater must be protected from freezing downdrafts during

shutdown periods.

The GPG 540A, 650A and 750A water heater are classified as a

category I appliance (non-positive vent pressure, non-condensing)

when installed with the supplied barometric draft control assembly

in a vertical vent installation.

The GPV 540A through 740A heater is classified as a category III

appliance (positive vent pressure, non-condensing) when installed

with supplied sidewall vent kits or direct vent kit.

All regulations pertaining to the venting of these heaters must

be followed.

The following vent installation instructions cover vertical, horizontal,

and direct vent applications.

VErTiCAL VENTiNG - FOr GPG MODELS

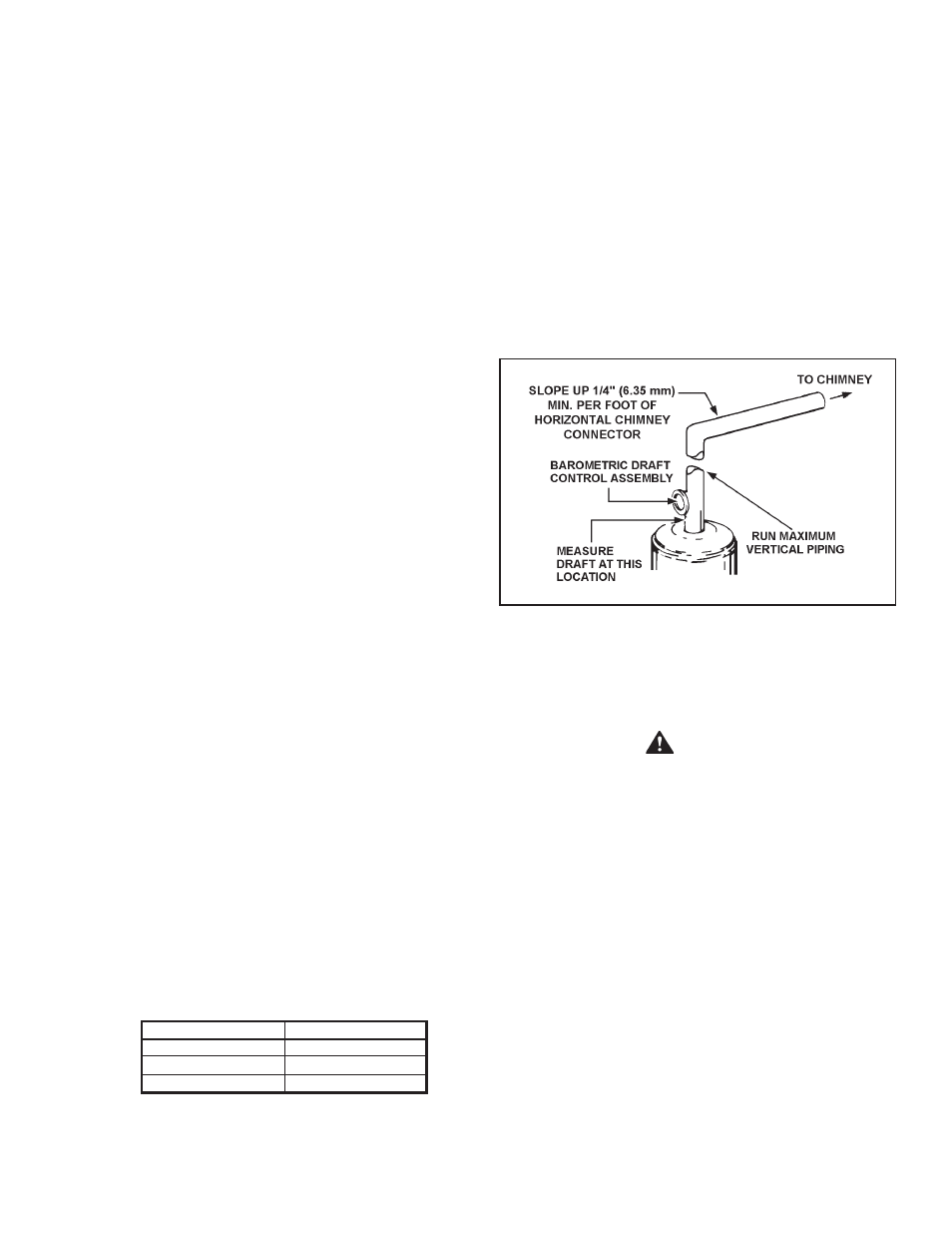

BArOMETriC DrAFT CONTrOL ASSEMBLy

A double-acting barometric draft control assembly is provided with

any unit intended for chimney venting. The purpose of this draft

control is twofold. During downdrafts it acts as a pressure relief

control to prevent the downdraft from blowing into the heater. It

also allows for makeup air to enter the chimney without being

drawn through the heater. In both cases the control prevents the

heater performance from being adversely affected by conditions

within the chimney.

The draft control assembly must be installed without alteration.

This assembly is factory adjusted for horizontal application only

and must be attached to the heater as shown in Figure 4. The

direction in which the outlet to the draft controls assembly faces

is arbitrary. The assembly must be fitted to the jacket cover such

that it is plumb and level to the ground. Fasten the draft control

assembly to the top cover using sheet metal screws at three

locations, or more, as required.

Damper or other obstructions must not be installed between the

heater and the barometric draft control assembly.

Do not adjust settings on gate.

When installed, the damper gate must pivot freely in the ring

guides. This gate will automatically adjust to regulate the chimney

draft imposed on the heater.

VENT CONNECTiONS

Vent connections must be made to an adequate stack or

chimney. Refer to the National Fuel Gas Code or to the vent pipe

manufacturer’s gas vent and chimney sizing table to properly

design and size the venting system. Refer to Table 1 for the vent

pipe size required for installation to the barometric draft control

assembly outlet.

TABLE 1.

Model

Flue Outlet

GPG-540A

9” (228.6 mm)

GPG-650A

9” (228.6 mm)

GPG-740A

9” (228.6 mm)

Single-wall or type B venting may be used with these heaters in

vertical vent installations. All local and utility regulations on venting

must be followed.

NOTE: A NEGATIVE DRAFT MUST BE MAINTAINED IN

VENTING.

A negative draft of 0.02” to 0.04” w.c. Must be maintained in

venting system. Measure draft at the location illustrated in

Figure 4. Adjust the control counter-weights if necessary as shown

in the MAINTENANCE portion of this manual.

Where an existing chimney or vent is to be used, be sure that the

chimney or vent has adequate capacity for the number and sizes

of gas appliances being vented through it. Inspect the chimney

or vent and remove all soot or other obstructions, which will retard

free draft.

Vent connectors making horizontal runs must have a minimum

upward slope toward the chimney or vent of ¼ inch per foot. Vent

connector length should be kept as short as possible. Be sure

that the vent pipe does not extend beyond the inside wall of a

chimney, see Figure 4.

FiGUrE 4.

In venting systems where a continuous or intermittent back

(positive) draft is found to exist, the cause must be determined and

corrected. In some cases, a special vent cap may be required.

wArNiNG

Failure to correct back drafts may cause air contamination

and unsafe conditions.

Do not connect the heater to a common vent or chimney with solid

fuel burning equipment. This practice is prohibited by many local

building codes as is the practice of venting gas fired equipment

to the ductwork of ventilation systems.

Connectors shall not be connected to a chimney, vent or venting

system served by a power exhauster, unless the connection is

made on the negative pressure side of the exhauster.

Do not connect any heater vented by natural draft to any vent

serving mechanical draft equipment operating under positive vent

pressure such as category III or category IV appliances.

HOriZONTAL (SiDE-wALL) VENTiNG -

FOr GPV MODELS

An exhaust vent hood, vent hood and a flue reducer are supplied

with any unit intended for through-the-wall horizontal venting.

These parts must be installed without alteration. The vent hood

adapter is designed for use with Selkirk Metalbestos Model PS

or Model G venting, see Figure 7 on page 10.