Table elevation leadscrew, Power feed gears – Southbend South Bend SB1027 User Manual

Page 48

-46-

For Machines Mfg. Since 8/09

Model SB1027

M A I N T E N A N C E

Table Elevation Leadscrew

Grease Type .........................NLGI 2 or Equivalent

Grease Amount ...................................... Thin Coat

Check/Add Frequency ............40 hrs. of Operation

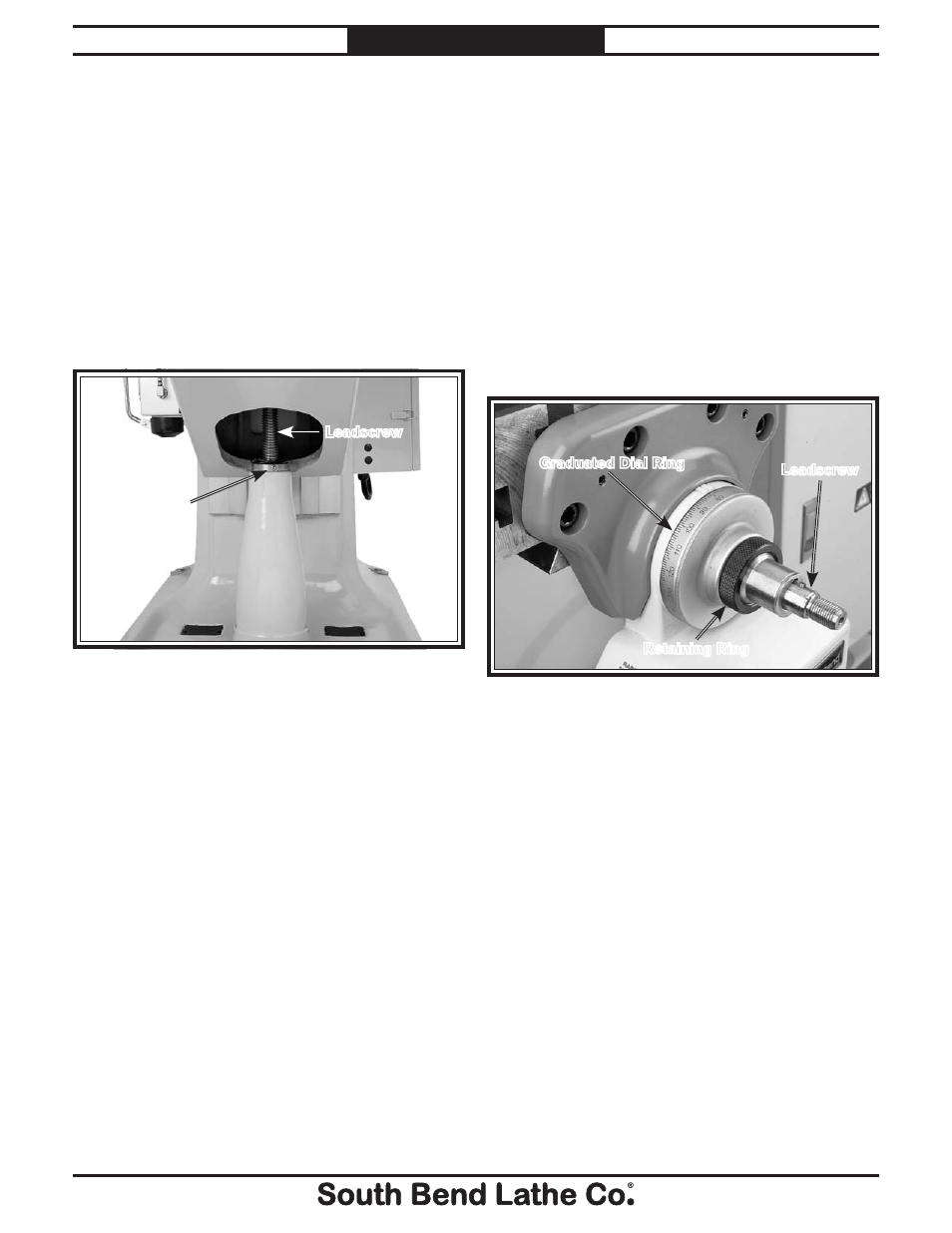

Elevate the table all the way up, then use

mineral spirits to clean any debris and built-up

grime from the elevation leadscrew threads. Add

one pump from a grease gun to the leadscrew

grease fitting shown in Figure 52, then run

the knee up and down to distribute the grease.

Repeat this process until the entire leadscrew is

covered with a thin coat of lubricant.

Power Feed Gears

Grease Type .......Medium-Weight Lithium Grease

Grease Amount ...........Two Pumps of Grease Gun

Check/Add Frequency ............40 hrs. of Operation

Tool Needed

Qty

Wrench 19mm .......................................................1

To lubricate the power feed gears:

1. DISCONNECT MACHINE FROM POWER!

2. Remove the hex nut and ball handle from the

power unit end of the longitudinal leadscrew

(see Figure 53).

Figure 52. Table elevation leadscrew and grease

fitting.

Grease

Fitting

Leadscrew

Figure 53. Power feed ball handle removed.

Graduated Dial Ring

Retaining Ring

Leadscrew

3. Unthread and remove the knurled retaining

ring and graduated dial ring from the end of

the leadscrew.