Lubrication, Cleaning, Unpainted & machined surfaces – Southbend South Bend SB1027 User Manual

Page 45

For Machines Mfg. Since 8/09

Model SB1027

-43-

M A I N T E N A N C E

Lubrication

The mill has numerous moving metal-to-

metal contacts that require regular and proper

lubrication to ensure efficient and long-lasting

operation, and to protect your investment.

Other than the lubrication points covered in

this section, all other bearings are internally

lubricated and sealed at the factory. Simply leave

them alone unless they need to be replaced.

Before performing any lubrication task,

DISCONNECT THE MILL FROM POWER!

Important: Before adding lubricant, clean the

debris and grime from the oil cup or grease

fitting and the immediate area to prevent

contamination of the oil cups, grease fittings, or

new lubricant.

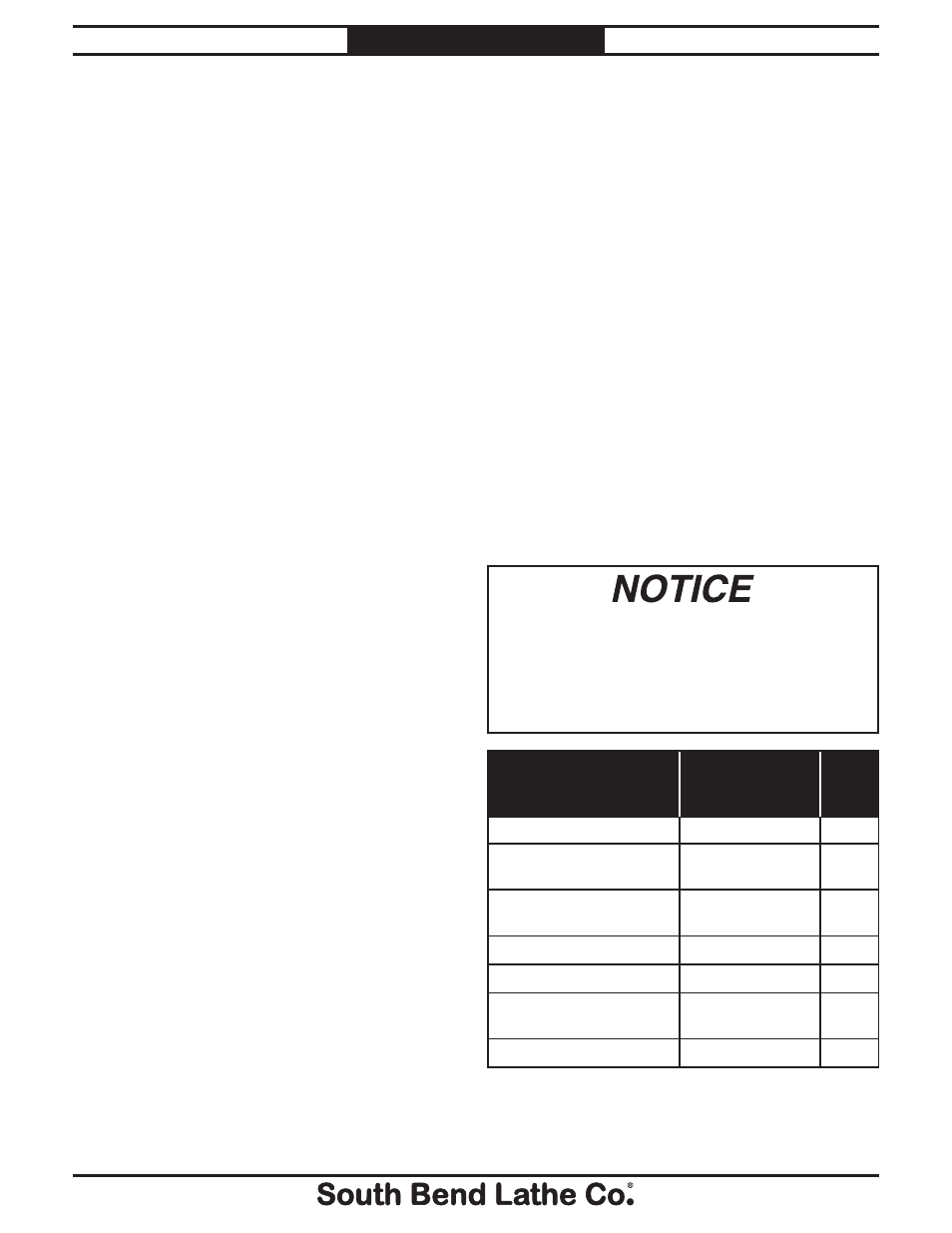

Use the schedule and information in Figure 45

as a daily guide for lubrication tasks.

The following recommended lubrication

schedule is based on light to medium mill

usage. Keeping in mind that lubrication helps

to protect the value and operation of the mill,

you may need to perform the lubrication tasks

more frequently depending on your usage.

Lubrication Task

Frequency

(Hours of

Operation)

Page

Ref.

Quill

3–4 hrs.

44

Table Ways (One-Shot

Oiler)

4–8 hrs.

44

Speed Range Bearing

Sleeve

40 hrs.

45

Headstock Gearing

40 hrs.

45

Ram Ways

40 hrs.

45

Table Elevation

Leadscrew (Z-Axis)

40 hrs.

46

Power Feed Gears

160 hrs.

46

Figure 45. Recommended lubrication tasks,

schedules, and instruction page references.

Cleaning

Regular cleaning is one of the most important

steps in taking good care of this machine. Each

operator is responsible for cleaning the machine

immediately after using it or at the end of the

day. We recommend that the cleaning routine

be planned into the workflow schedule, so that

adequate time is set aside to do the job right.

Typically, the easiest way to clean swarf from the

ways and table is to use a wet/dry shop vacuum

that is dedicated for this purpose only. The small

chips leftover after vacuuming can be wiped up

with a slightly oiled rag. Avoid using compressed

air to blow off chips, as it may drive them deeper

into moving surfaces and could cause sharp chips

to fly into your face or hands.

All visible swarf should be removed from the mill

during cleaning. Remember, personal neatness

gives you personality!

Unpainted & Machined Surfaces

Besides the ways and elevation leadscrew, all

other unpainted and machined surfaces should

be wiped down daily to keep them rust-free

and in top condition. This includes surface you

can find that could be vulnerable to rust if left

unprotected (this especially includes any parts

that may be exposed to water soluble cutting

fluids). Typically with these parts, a thin film of

oil is all that is necessary for protection.