Leveling & mounting, Bolting to concrete floors, Leveling – Southbend South Bend SB1027 User Manual

Page 19

For Machines Mfg. Since 8/09

Model SB1027

-17-

P R E P A R A T I O N

Bolting to Concrete Floors

Leveling & Mounting

Leveling

Figure 6. Example of a precision level.

Leveling machinery helps precision components,

such as bed ways, remain straight and flat

during the lifespan of the machine. Components

on an unleveled machine may slowly twist due to

the dynamic loads placed on the machine during

operation.

To level a machine, place metal shims under

the contact points where the machine rests on

the floor. For best results, use a precision level

that is at least 12" long and sensitive enough to

show a distinct movement when a 0.003" shim

(approximately the thickness of one sheet of

standard newspaper) is placed under one end of

the level. See the figure below for an example of a

high precision level.

We strongly recommend securing your

machine to the floor if it is hardwired to the

power source. Consult with your electrician to

ensure compliance with local codes.

Although not required, we recommend that

you level your machine and mount it to the

floor. Because this is an optional step and floor

materials may vary, mounting hardware is not

included. Generally, you can either bolt your

machine to the floor or mount it on machine

mounts.

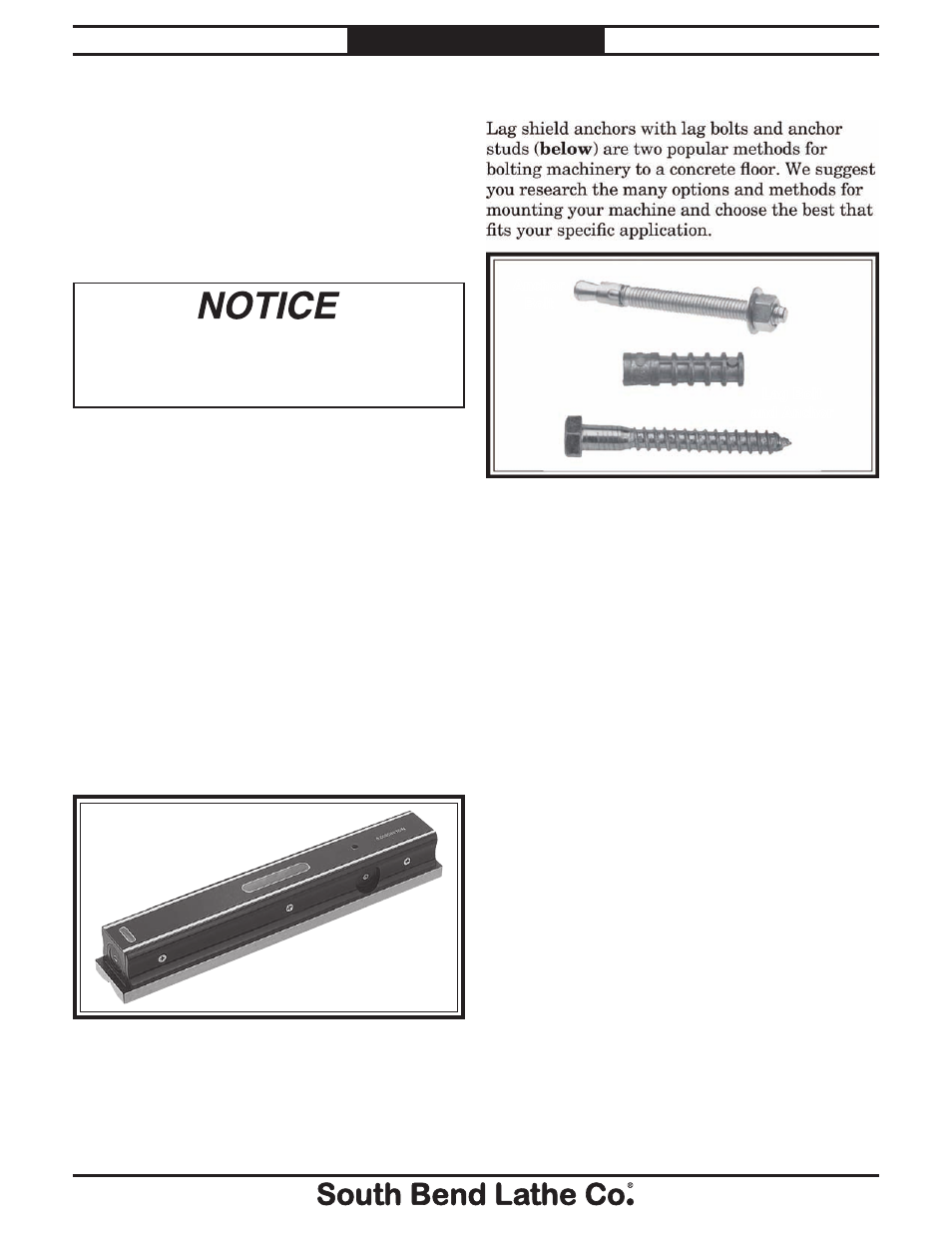

Figure 7. Common types of fasteners for bolting

machinery to concrete floors.

Lag Bolt

and Anchor

Anchor

Bolt