Parts, Se rv ic e – Woodstock M1109 User Manual

Page 45

-43-

M1109 Combo Lathe/Mill

SE

RV

IC

E

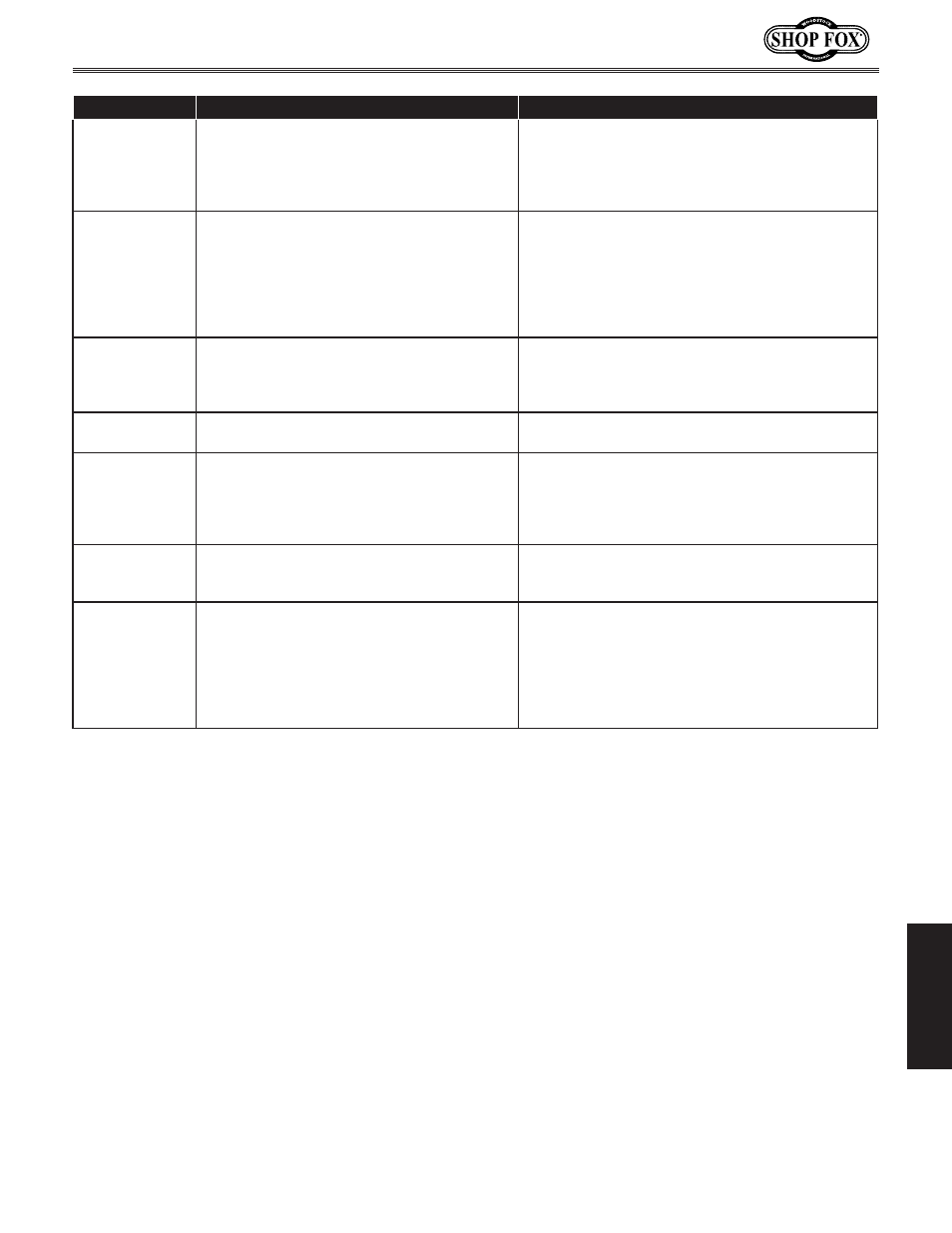

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Loud, repetitious

noise coming

from machine

at or near the

motor.

1. Pulley setscrews or keys are missing or loose.

2. Motor fan is hitting the cover.

1. Inspect keys and setscrews. Replace or tighten if

necessary.

2. Tighten fan or shim cover, or replace items.

Carriage hard to

move.

1. Carriage lock is tightened down.

2. Chips have loaded up on bedways.

3. Bedways are dry and in need of lubrication.

4. Longitudinal stops are interfering.

5. Gibs are too tight.

1. Check to make sure table locks are fully released.

2. Frequently clean away chips that load up during

turning operations.

3. Lubricate bedways and handles.

4. Check to make sure that stops are floating and not

hitting the center stop.

5. Loosen gib screw(s) slightly.

Gear change

levers will not

shift into posi-

tion.

1. Gears not aligned in headstock.

1. Rotate spindle by hand until gear falls into place.

Motor overheats. 1. Motor overloaded.

2. Air circulation through the motor restricted.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

Loud, repetitious

noise coming

from machine.

1. Gears not aligned in headstock or no back-

lash.

2. Broken gear or bad bearing.

3. Workpiece is hitting stationary object.

1. Adjust gears and establish backlash.

2. Replace broken gear or bearing.

3. Stop lathe immediately and correct interference

problem.

Tailstock quill

will not feed out

of tailstock.

1. Quill lock lever is tightened down.

1. Turn lever counterclockwise.

Motor is loud

when cutting.

Overheats or

bogs down in the

cut.

1. Excessive depth of cut or feed rate.

2. RPM or feed rate wrong for cutting

operation.

3. Cutting tool is dull.

4. Gear setup is too tight, causing them to

bind.

1. Decrease depth of cut or feed rate.

2. Refer to RPM feed rate chart for appropriate rates.

3. Sharpen or replace the cutting tool.

4. Readjust the gear setup with a small amount of

backlash so the gears move freely and smoothly

when the chuck is rotated by hand.

PARTS