Service, Cross slide backlash – Woodstock M1109 User Manual

Page 38

-36-

M1109 Combo Lathe/Mill

SE

RV

IC

E

SERVICE

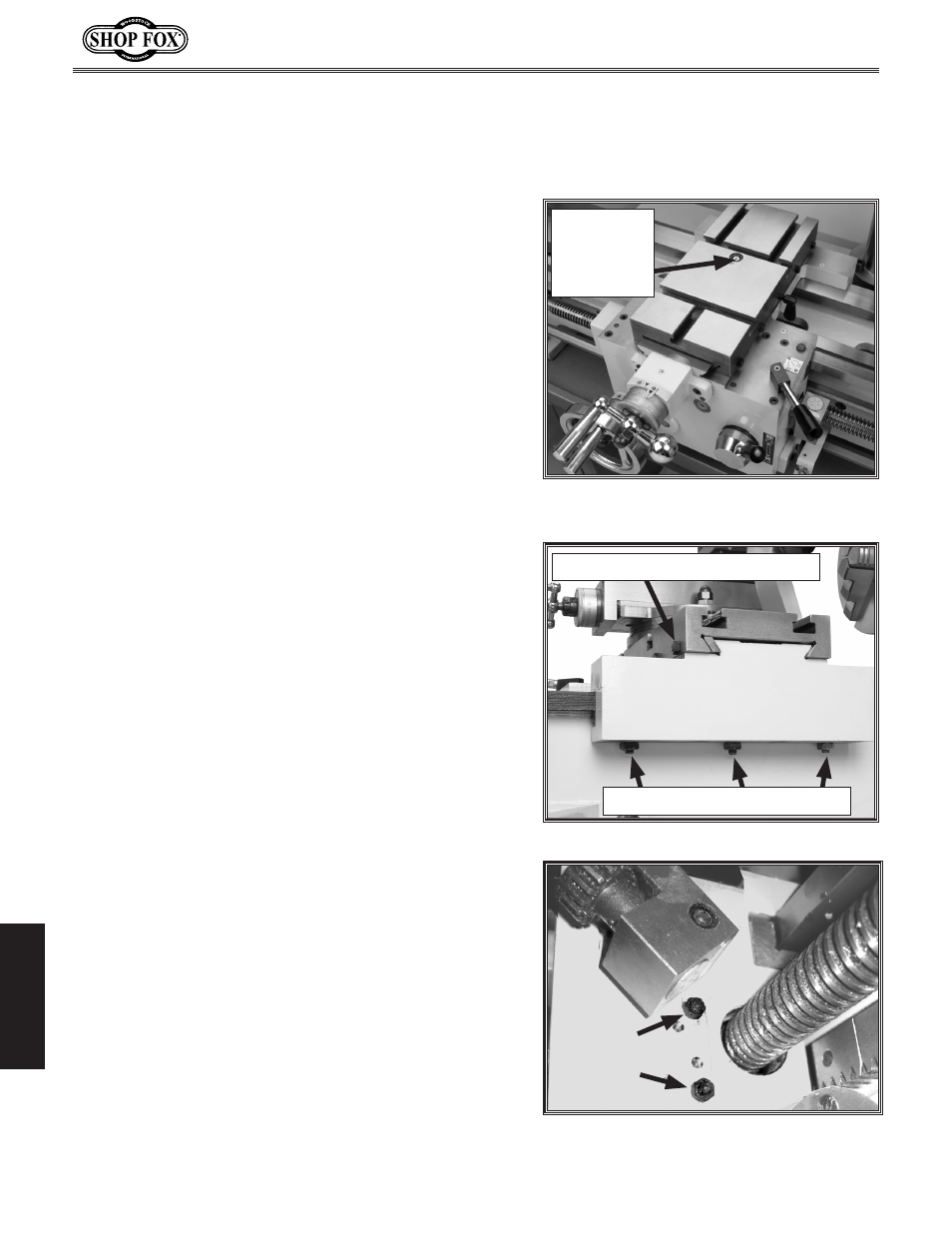

Figure

59

. Cross slide backlash

adjustment cap screw.

Figure 60. Gib adjustment points.

Cross Feed

Backlash

Adjustment

Cap Screw

Saddle Gib Adjustment Points

Cross Slide Gib Adjustment Point

Figure 61. Half-nut gib adjustment

location (thread dial is swung out of the

way for gib adjustment).

Cross Slide Backlash

Backlash is the amount of play found in a lead screw.

It can be found by turning the cross slide handwheel in

one direction, and then turning the handwheel the other

direction. When the cross slide begins to move, the back-

lash has been taken up.

Note: Avoid the temptation to overtighten the cross slide

backlash screw. Overtightening will cause excessive wear

to the sliding block and lead screw.

Backlash is adjusted by tightening or loosening the screw

shown in

Figure 59. This screw draws a wedge-type nut

against the lead screw and main nut. If you get it too

tight, loosen the screw a few turns and tap the cross feed

a few times with a rubber or wooden mallet. Then turn

the handle slowly back and fourth until the handle turns

freely. To readjust the backlash, rock the handle back and

fourth and tighten the screw slowly until the backlash

is at approximately 0.001" to 0.002" as indicated on the

handwheel dial.

Note: Reducing backlash to less than 0.001" is impractical

and reduces the life of the cross slide.

Cross Slide, Half-Nut,

and Compound Slide Gib

Adjustments

When adjusting these gibs (

Figures 60 and 61), keep in

mind that the goal is to remove sloppiness in the ways

without causing the slides or half nut to bind. Loose gibs

will cause a poor finish on the workpiece and may cause

undue wear on the slide. Over-tightening may cause pre-

mature wear on the slide, lead screw, and half-nut. The

cross slide gib is a tapered piece of iron. When the oppos-

ing front and rear gib adjustment screws are turned in

opposing directions, the screws force the tapered gibs to

fill the loose void in the way, thus tightening the play in

the cross slide. If more play is needed turn the screws the

other direction.

For the four saddle gibs, (

Figure 60) loosen the jam nuts

and turn the three set screws until there is slight tension

felt and the gib plates are slightly preloaded against the

underside of the flat-way. Tighten the jam nuts when fin-

ished.