Chuck and faceplate mounting – Woodstock M1109 User Manual

Page 17

-15-

M1109 Combo Lathe/Mill

O

PE

R

AT

IO

N

S

Chuck and Faceplate

Mounting

The three-jaw scroll chuck has hardened steel jaws that

self-center the workpiece within 0.002"-0.003". An extra

set of jaws is included for machining larger workpieces.

The four-jaw chuck also has hardened steel jaws but are

adjusted independently to hold an off-center workpiece.

Each jaw can be removed from the chuck body and

reversed for special clamping applications.

The cast-iron faceplate has slots for T-bolts that hold

clamping fixtures. This face plate and aftermarket clamp-

ing hardware will hold non-cylindrical parts such as cast-

ings for many types of turning operations.

Both chucks and the faceplate are removed and installed

the same way.

To remove and install the chuck or face plate, do these

steps:

1. DISCONNECT POWER TO THE LATHE/MILL!

2. Lay a chuck cradle or protective layer of plywood

over the bedways to prevent your fingers from being

pinched and to protect the precision-ground surfaces

(see

Figure 15).

3. Use a 14mm wrench and loosen the three hex bolts

that secure the chuck to the spindle

Figure 16.

4. Support the chuck, and while anticipating the heavy

weight of the chuck, remove the three hex bolts and

then the chuck.

5. Clean the mating surfaces of the spindle and the

new chuck or faceplate with a clean oiled rag.

6. Position the other chuck or faceplate on the spindle

flange making sure it is fully seated, and tighten the

hex bolts in several alternating sequences.

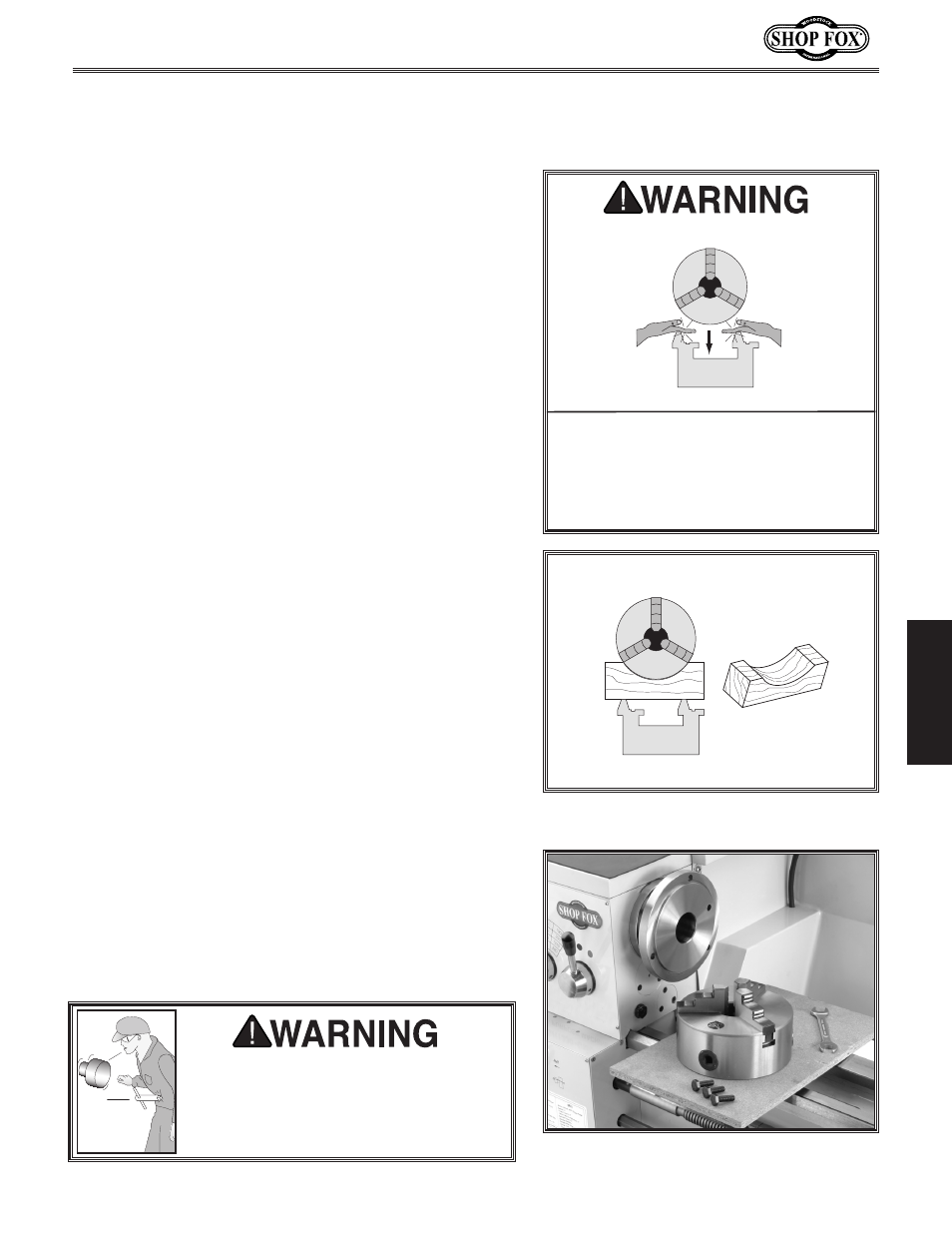

PINCH HAZARD! Protect your hands

and precision ground bedways with

plywood when removing lathe/mill

chuck! The heavy weight of a fall-

ing chuck can cause serious injury.

Figure 15. Simple chuck cradle made of

scrap lumber.

Figure 16. Chuck, hex bolts, and spindle

flange.

Securely clamp your workpiece and

remove the chuck key! Thrown objects

from a lathe/mill can cause serious injury

or death to the operator and to bystand-

ers many feet away.