Maintenance – Woodstock M1109 User Manual

Page 36

-34-

M1109 Combo Lathe/Mill

M

A

IN

TE

N

A

N

CE

MAINTENANCE

Regular periodic maintenance of your lathe/mill will

ensure optimum performance. Make a habit of inspecting

your machine each time you use it.

Check for the following conditions and repair or

replace when necessary:

• Loose mounting bolts and chuck.

• Worn switch or safety features.

• Worn or damaged cords and plugs.

• Any other condition that could hamper the safe

operation of this machine.

Clean your machine every day or more often as needed.

Make sure to unplug the lathe/mill before cleaning it.

Never blow the lathe/mill off with compressed air, oth-

erwise you will force metal shavings deep into mecha-

nisms. Remove chips as they accumulate with rags,

brushes, and a shop vacuum. Chips left on the machine

soaked with water-based coolant will eventually invite

oxidation and a gummy residue build up around moving

parts. Cleaning will help keep your lathe/mill running

smoothly. Always be safe and responsible with the use

and disposal of cleaning products.

Never use acetone, gasoline, or lacquer thinner to

remove stains or oil from painted surfaces. These chemi-

cals will melt the paint. Use mineral spirits or mild

household degreasers.

General Cleaning

General Maintenance

General Lubrication

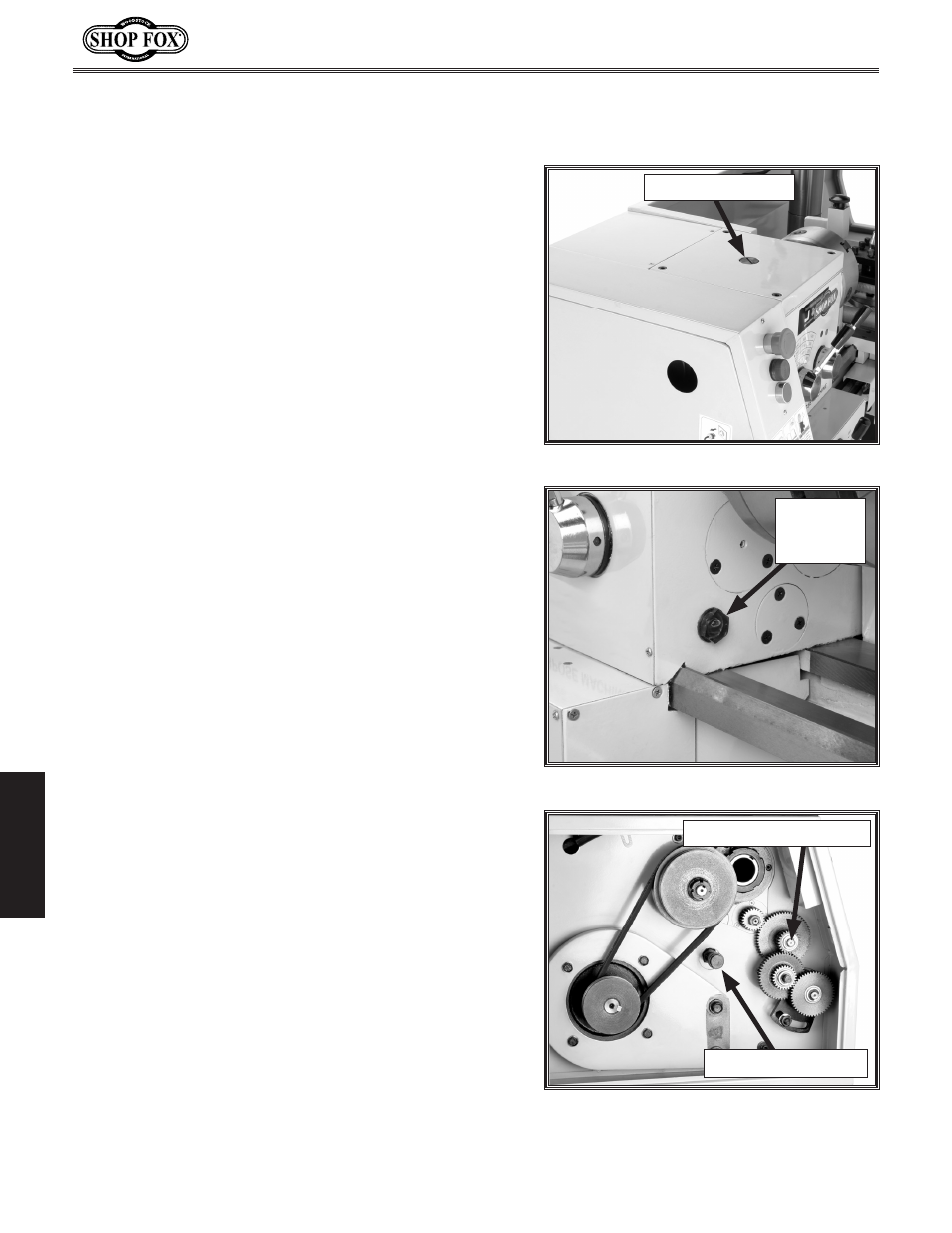

Keep the headstock oil level at

3

⁄

4

full (

Figure 54). After

break-in, change the oil in the headstock with Mobil

®

DTE

®

Heavy-Medium or an equilivant grade of oil immediately

and then again after three months. After that, change the

oil at the same time on an annual basis or more frequent-

ly if extreme machine use requires it.

To control surface rust on machined surfaces, wipe the

unprotected metal as required with a rust inhibiting oil.

Paint all gears in

Figure 55 with a good quality automo-

tive wheel bearing grease as required to keep lubricated.

Figure 55. Headstock and gear box drain

locations.

Figure 54. Headstock oil level sight glass.

Figure 53. Headstock fill plug.

Headstock

Oil Level

Sight Glass

Gear Spindle Ball Oiler

Headstock Oil Drain

Headstock Oil Fill