Notice, Adjusting/replacing the v-belt – Woodstock M1109 User Manual

Page 37

-35-

M1109 Combo Lathe/Mill

M

A

IN

TE

N

A

N

CE

For daily lubrication, use a manual oil gun with a general

10W machine oil to lubricate the following 15 ball oiler fit-

tings. See

Figure 56 for some typical locations. Wipe off

all oil ball fittings with a rag, and then oil the following

locations:

• Cross Feed Table (1 ball oiler on top)

• Cross Feed Handwheel (1 ball oiler on top)

• Saddle Ways (2 ball oilers on top)

• Apron Handwheel Gear Axle (1 ball oiler on apron face)

• Compound Rest (1 ball oiler on top)

• Tailstock Barrel (1 ball oiler on top)

• Tailstock Handwheel (1 ball oiler on right side)

• Lead Screw Endcap Bushing (1 ball oiler, see

Figure 57)

• Change Gear Spindle (1 ball oiler on end of shaft)

• Gear Spindle Ball Oiler (1 ball oiler, see

Figure 55)

• Gearbox (4 ball oilers on top)

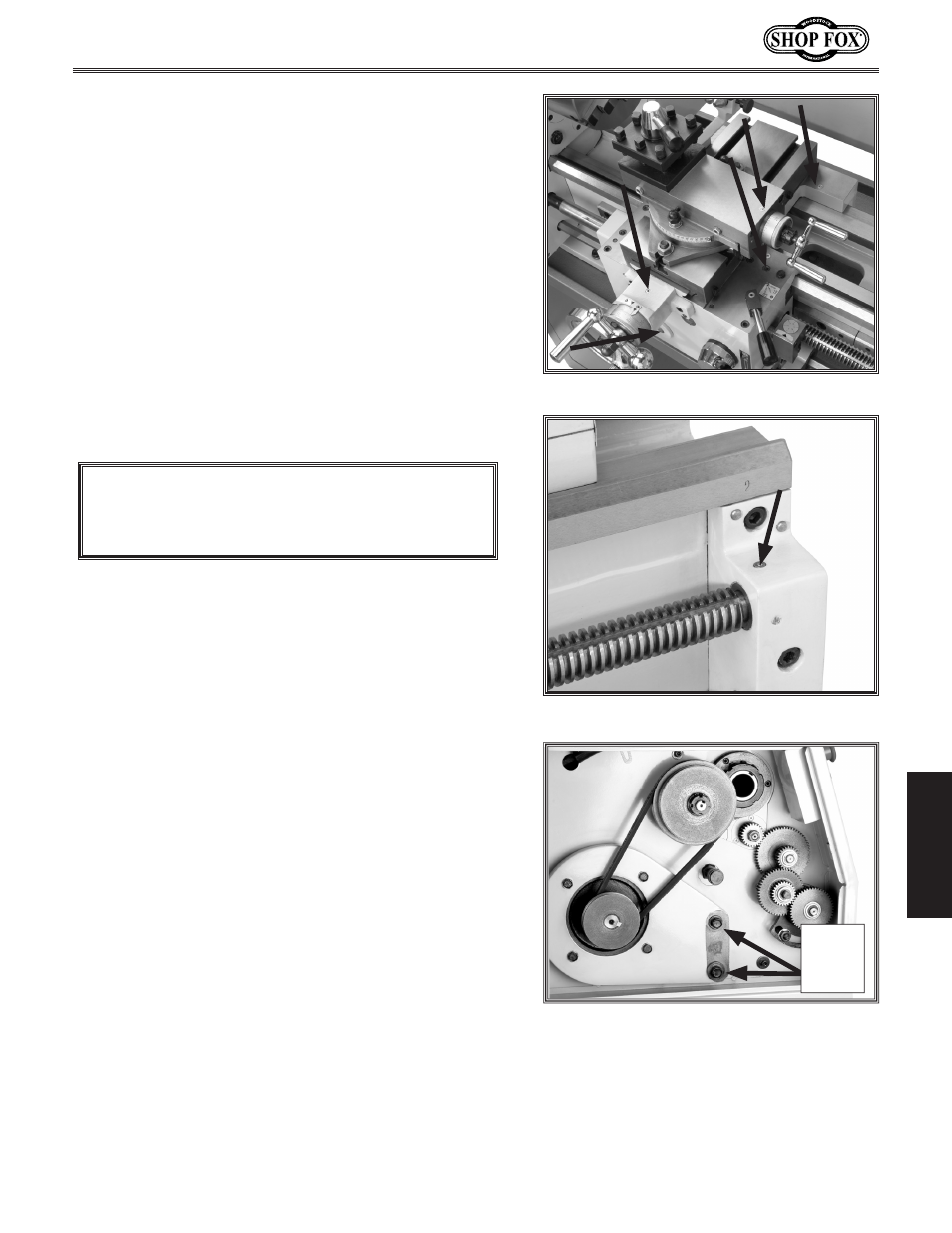

Figure 56. Typical ball fitting locations.

Failure to follow lubrication guidelines will lead

to rapid deterioration of lathe/mill components.

NOTICE

Figure 57. Lead screw end cap bushing.

Figure 58. Motor mount bolts.

Adjusting/Replacing

the V-Belt

To replace or adjust the V-belts, do these steps:

1. DISCONNECT POWER TO THE LATHE/MILL!

2. Open the change gear access door (Figure 58).

3. Loosen the four motor access cover screws, and lift

the cover off (

Figure 58).

4. Using a 17mm wrench, loosen the two motor mount

bolts shown in

Figure 58.

5. Grasp the motor and lift upward to de-tension the

belt and remove the belt.

6. Use solvent to clean the pulleys of oil and install the

new belt.

7. Let the motor hang to tension the belt, and tighten

the two motor mount bolts.

8. Close the access door and latch it shut.

Motor

Mount

Bolts