2 basic operation, Front panel controls & basic operation english, 1 general – Siemens G85139 User Manual

Page 15: 2 initial testing

3. FRONT PANEL CONTROLS & BASIC OPERATION

English

© Siemens plc 1997

G85139-H1750-U049-B

15

26/09/97

3.2 Basic Operation

Refer to section 5 for a full description of each parameter.

3.2.1 General

(1) The inverter does not have a main power switch and is live when the mains supply is connected. It waits,

with the output disabled, until the RUN button is pressed or for the presence of a digital ON signal at

terminal 5 (rotate right) or terminal 6 (rotate left) -

see parameters P051 - P053.

(2) If output frequency is selected to be displayed (P001 = 0), the corresponding setpoint is displayed

approximately every 1.5 seconds while the inverter is stopped.

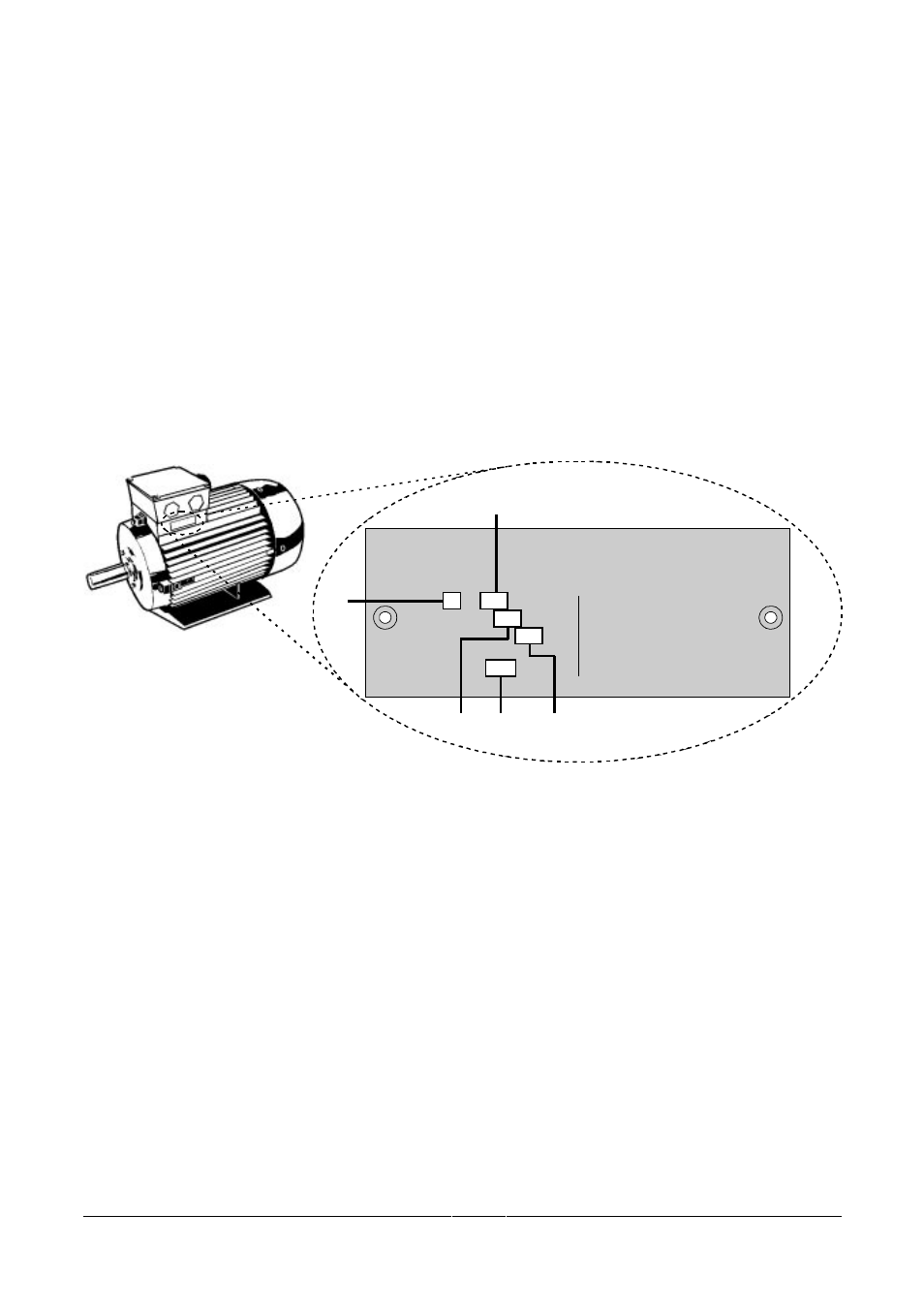

(3) The inverter is programmed at the factory for standard applications on Siemens four-pole standard

motors. When using other motors it is necessary to enter the specifications from the motor’s rating plate

into parameters P081 to P085

(see Figure 10). Note: Access to these parameters is not possible

unless P009 has been set to 002 or 003.

3 Mot

IEC 56

IM B3

cos

ϕ

0,81

cos

ϕ

0,81

1LA5053-2AA20

Nr. E D510 3053

IP54

Rot. KL 16

I.Cl.F

12 022

60 Hz

440 V Y

0,34 A

0,14 kW

3310 /min

220/380 V

∆

/Y

0,12

2745

VDE 0530

S.F. - 1,15

/min

P081

P084

P083 P082

P085

0,61/0,35 A

50 Hz

kW

Figure 10: Typical Motor Rating Plate Example

Note:

Ensure that the inverter is configured correctly to the motor, i.e. in the above example delta

terminal connection is for 220 V.

3.2.2 Initial Testing

(1) Check that all cables have been connected correctly

(section 2) and that all relevant product and

plant/location safety precautions have been complied with.

(2) Apply mains power to the inverter.

(3) Ensure that it is safe to start the motor. Press the RUN button on the inverter. The display will change to 5.0

and the motor shaft will begin to turn. It will take one second for the inverter to ramp up to 5 Hz.

(4) Press the STOP button. The display will change to 0.0 and the motor slow to a complete stop within one

second.